Full-operating pre-coagulating type heat-source tower device

A technology of heat source tower and full working conditions, applied in the direction of machine operation, direct contact heat exchangers, heating methods, etc., can solve problems such as large energy consumption, frosting in heating, and increased solution regeneration load. Achieve the effects of improving overall performance, reducing consumption, and reducing the load of solution regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

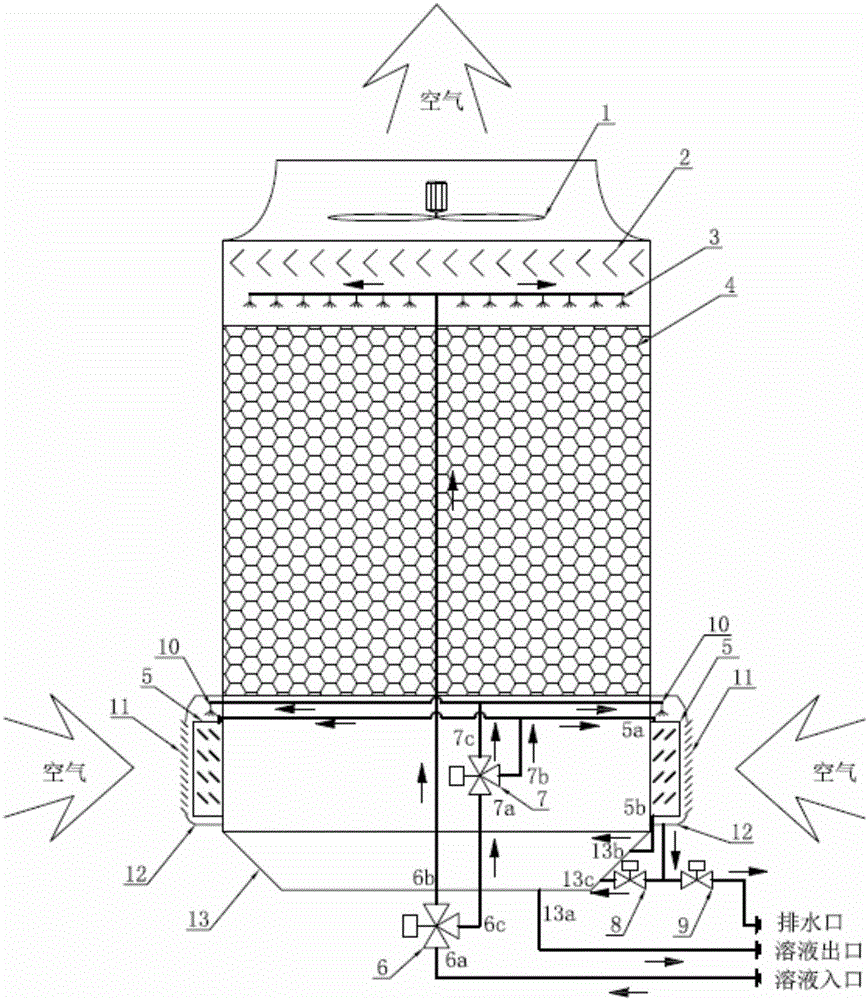

[0020] The present invention provides a pre-condensation type heat source tower device operating under all working conditions, the principle diagram of which is as follows figure 1 As shown, the heat source tower includes a heat source tower body and a main solution circuit, a precondensation and spray frost suppression circuit and an air circuit arranged in the tower body.

[0021] The main solution circuit includes the liquid distributor 3, the filler 4, the liquid collection tank 13, the first electric three-way valve 6 and its connecting pipes arranged sequentially from top to bottom; in the main solution circuit, the solution inlet port of the heat source tower is connected to the first The inlet 6a of the electric three-way valve, the first outlet 6b of the first electric three-way valve are connected to the inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com