Test bed valve sealing and operation characteristic detection system and detection method

A technology of valve sealing and detection system, which is applied in the direction of liquid tightness measurement, measuring device, and mechanical component testing using liquid/vacuum degree, which can solve the problems of interference mixed with unreliable data, low accuracy and efficiency, and poor stability. , to achieve the effect of improving work efficiency and accuracy, high degree of automation and precision, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Preferred modes of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0042] 1. System composition and working principle

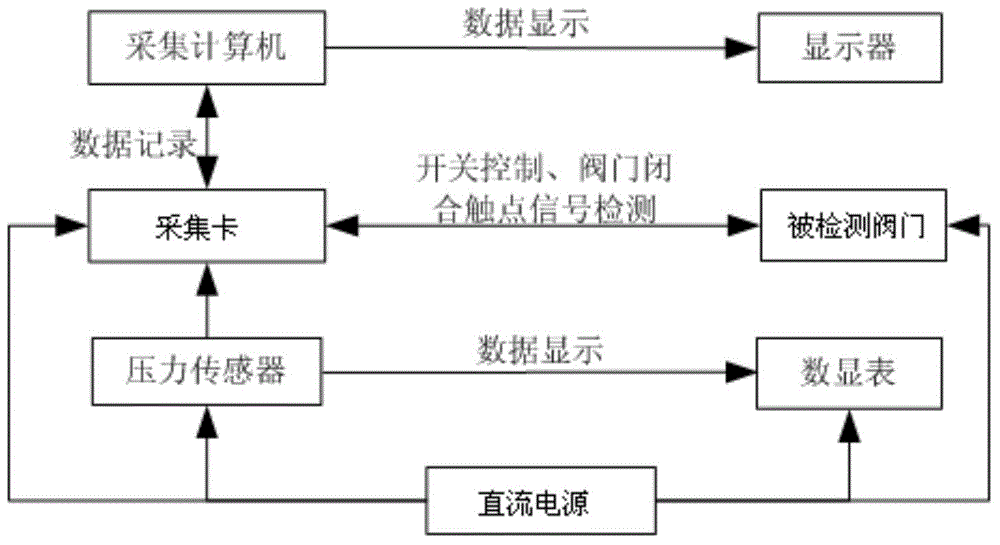

[0043] This system is used to test the performance of the valves used in the test bench, control the solenoid valve of the process system, measure and record the relevant pressure and valve closing detection signal at the same time, and realize the valve action performance test and sealing test of the test bench. The measurement accuracy reaches 0.2%, the control ability range is wide, and the control time accuracy is 1ms.

[0044] 1.1 System composition

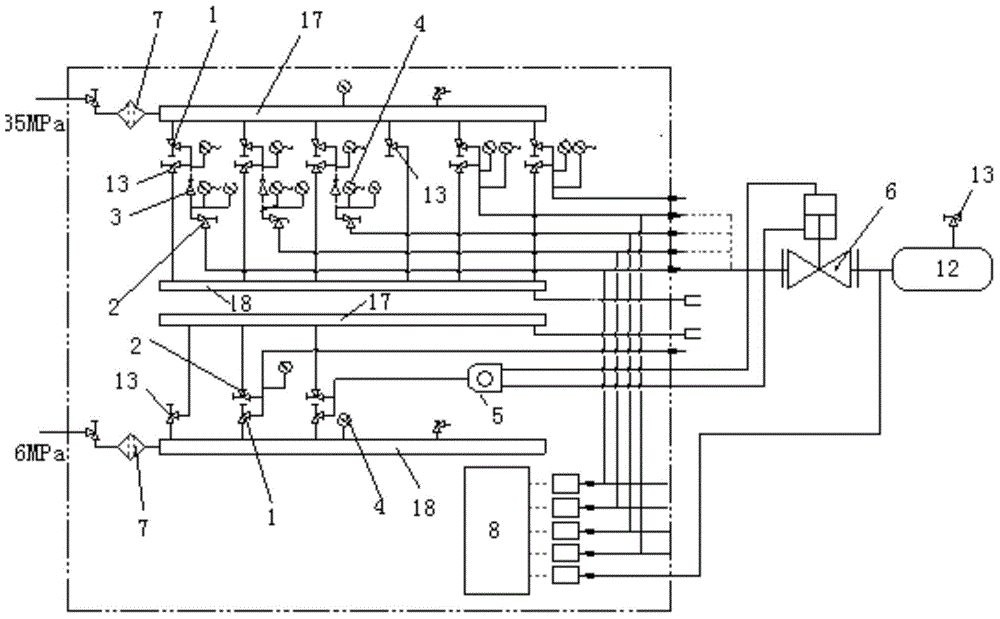

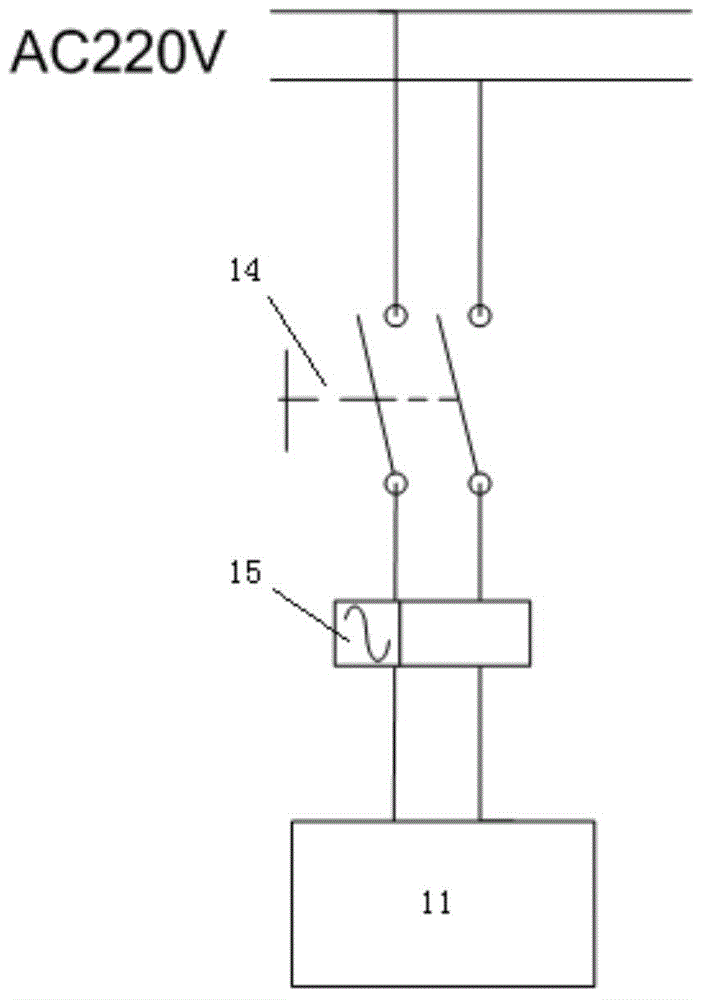

[0045] The valve sealing and action characteristic detection system of the test bench is composed of a gas circuit system and a measurement and control system, see figure 1 . Among them, the gas circuit system consists of gas source (the gas source pressure includes 35MPa high-pressure gas and 6MPa control gas, both of which are delivered to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com