Method for calibrating focal plane of invisible light transmission optical system through supplementary lens

A technology for attaching lenses and optical systems, applied in the field of optical detection, can solve the problems of difficult operation, difficult to meet, low efficiency, etc., and achieve the effect of strong operability, strong adaptability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] The present invention provides a method for calibrating the focal plane of an invisible light transmission optical system with an additional lens, specifically comprising the following steps:

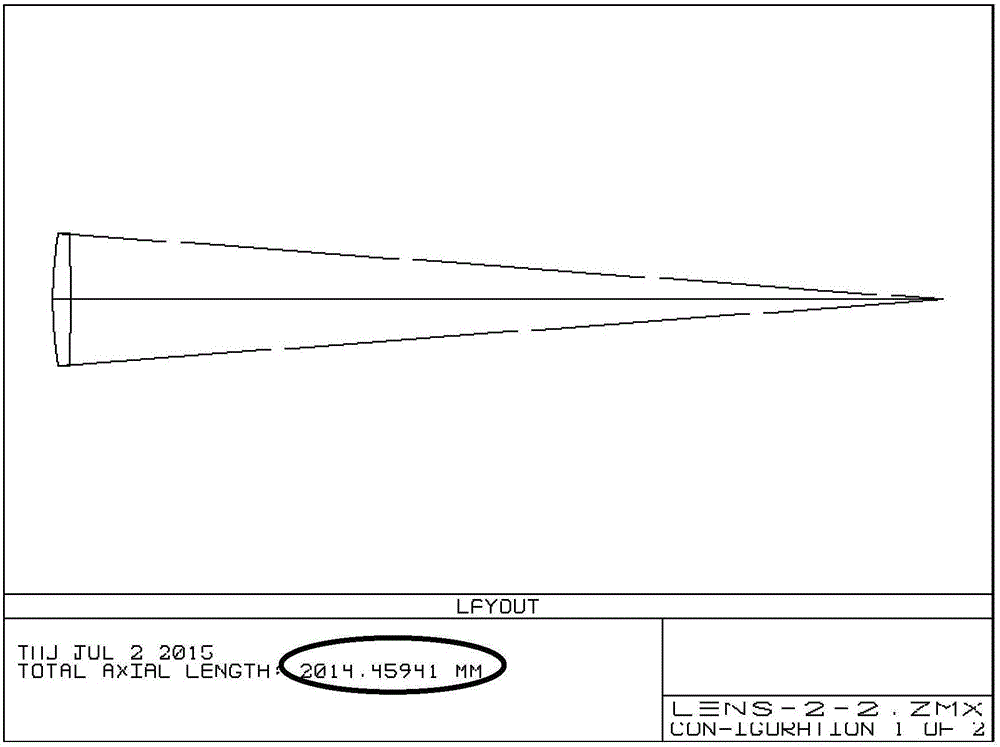

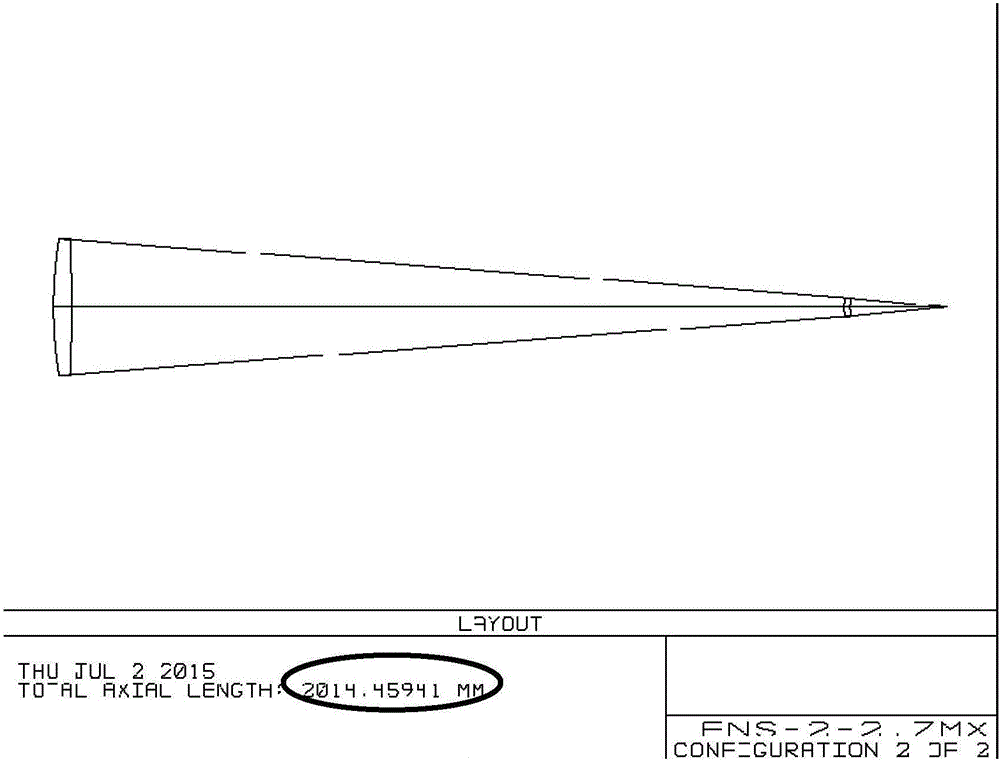

[0024] 1. ZEMAX software calculates the focal plane position or optical total length of the lens or optical system to be calibrated in the invisible light working band (see figure 1 , ellipse circle);

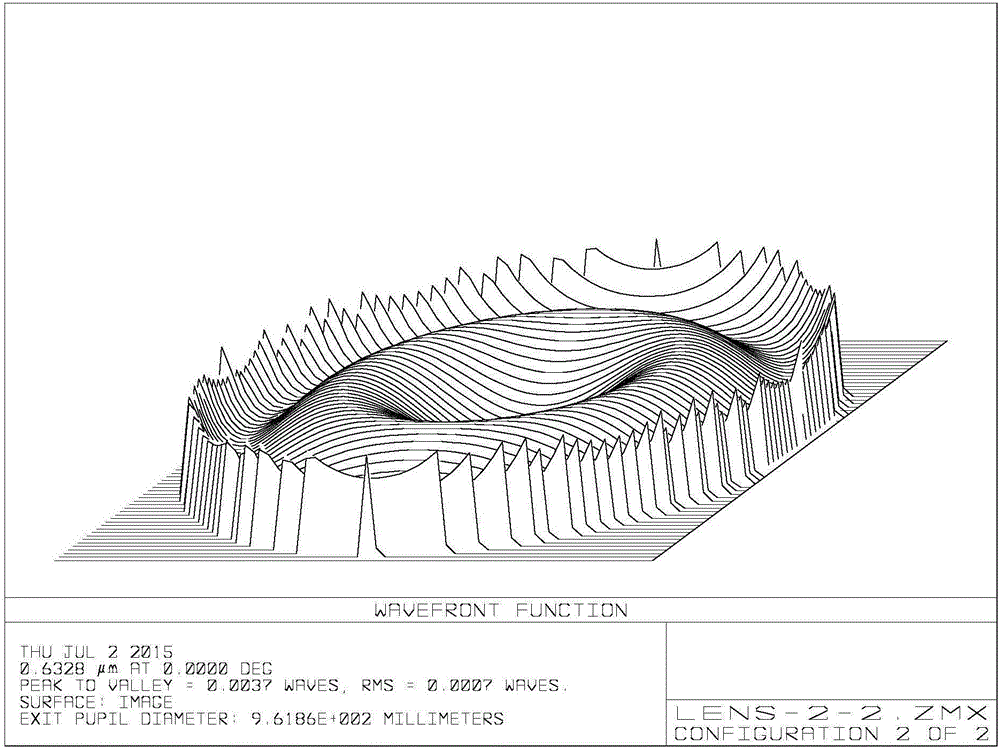

[0025] 2. Use the ZEMAX multi-structure module to design additional lenses, requiring the total optical length of the system or the additional back intercept "total optical thickness" to be equal to the back intercept of the lens or system to be calibrated, see figure 1 and figure 2 At the place marked with a red circle, it is also required that the image quality of the combined system should be better (the image quality requirement should not be lower than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com