Cable trench automatic inspection device

An automatic inspection and ditch automatic technology, applied to measuring devices, two-dimensional position/channel control, instruments, etc., can solve problems such as difficult work, aging and brittle organic insulating materials, and easy fire caused by cable operating temperature. Achieve the effect of improving the level of automation and intelligence, improving the working environment of personnel, and improving the efficiency of monitoring work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

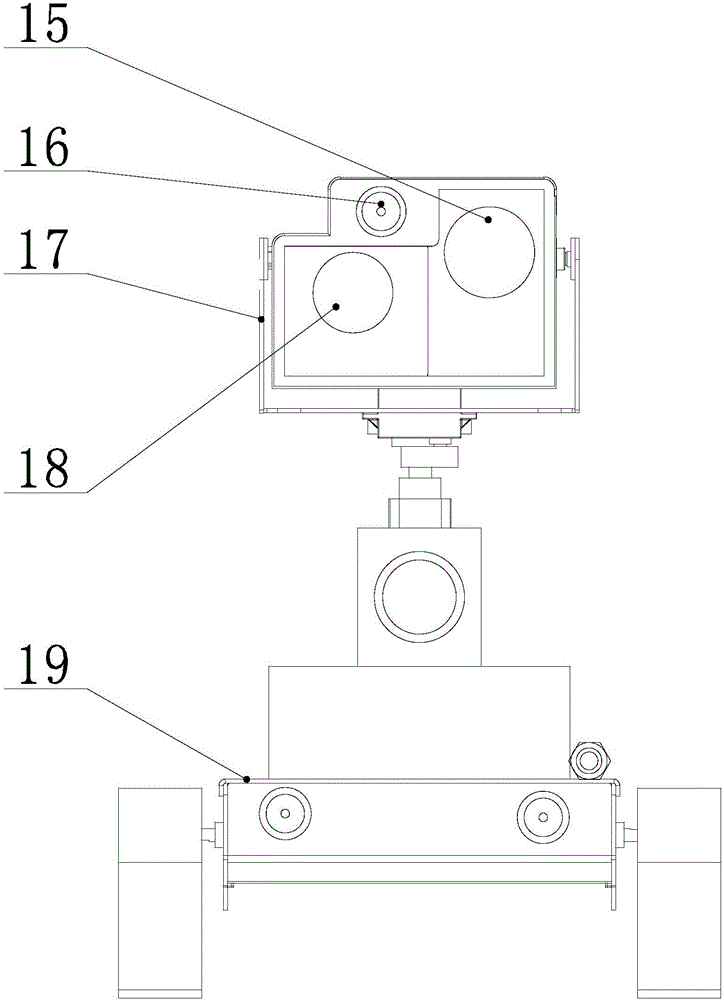

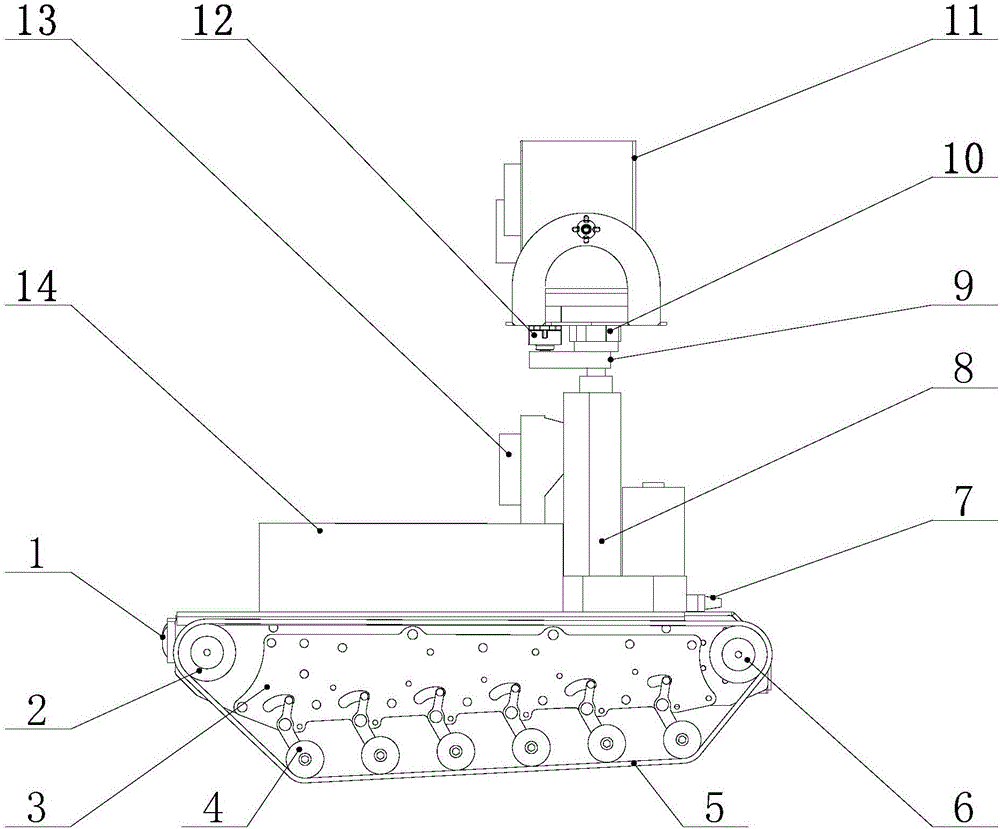

[0020] see figure 1 and figure 2 , the cable ditch automatic inspection device of the present invention comprises a mobile chassis, the mobile chassis adopts a crawler trolley, and a temperature and humidity sensor 7, a road detection camera 13, a data storage device and a power supply for the entire automatic inspection device are installed on the dolly body. Power supply, the front end of the car body is also equipped with an illuminating lamp 1, and an electric push rod 8 is installed vertically on the car body. There are two pan-tilt motors 12, the top of the electric push rod 8 is equipped with a synchronous toothed wheel 9, and the pan-tilt motor 12 is engaged with the synchronous toothed wheel 9 through a reduction gear to drive the pan-tilt 10 to rotate freely in the horizontal direction; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com