A Servo Pressure Control System

A servo pressure and control system technology, applied in the field of control, can solve problems such as poor real-time performance and complicated programming, and achieve the effect of low cost, simple control method, and good real-time continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

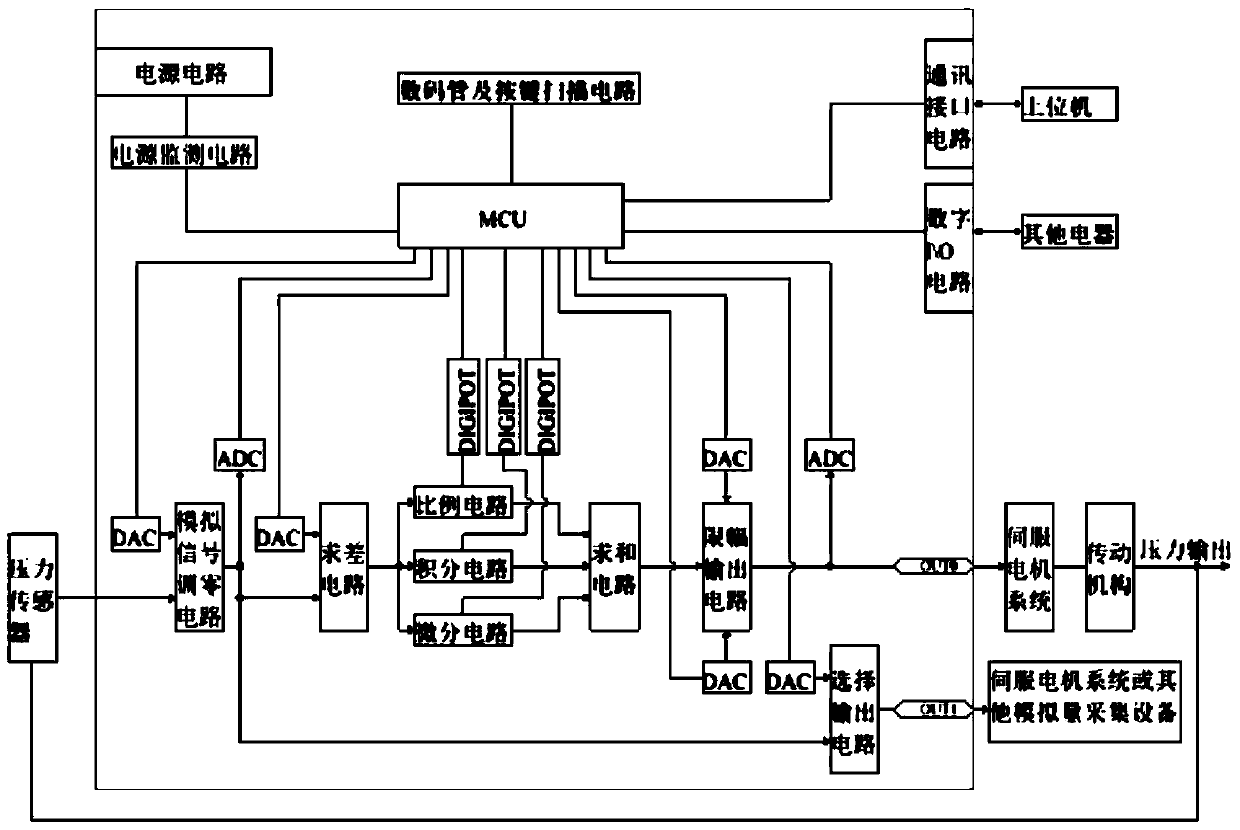

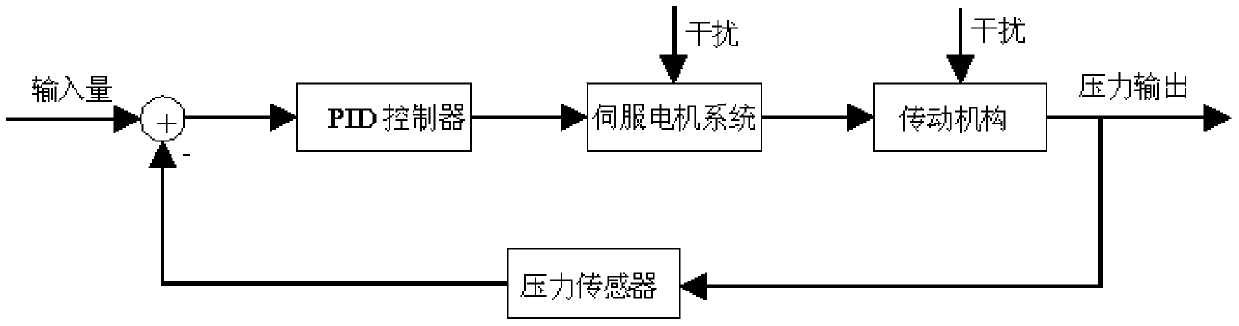

[0033] Such as figure 1 , a servo pressure control system, including a servo pressure controller, a pressure sensor, and a servo motor.

[0034] Such as figure 1 , the servo pressure controller includes MCU and single chip microcomputer minimum system circuit, digital tube and button scanning circuit, communication interface circuit, analog signal zero adjustment circuit, ADC circuit, DAC circuit, analog signal PID adjustment circuit, digital potentiometer circuit, analog Signal limiting output circuit, signal selection output circuit, digital I / O circuit.

[0035] Such as figure 1 , in the above servo pressure controller, the servo pressure controller is connected to the upper computer through a communication interface circuit.

[0036] Such as figure 1 , in the above servo pressure controller, the servo pressure controller is connected to the control panel through a digital tube and a button scanning circuit.

[0037] Such as figure 1 , in the above servo pressure cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com