Deep spray coating rotary cup

A multi-layer, internal and external rotation technology, applied in the direction of coating, spraying device, device for coating liquid on the surface, etc., can solve the problems of unbalanced outward force, uneven surface thickness, waste of raw materials, etc., and achieve the balance of outward force , uniform coating and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

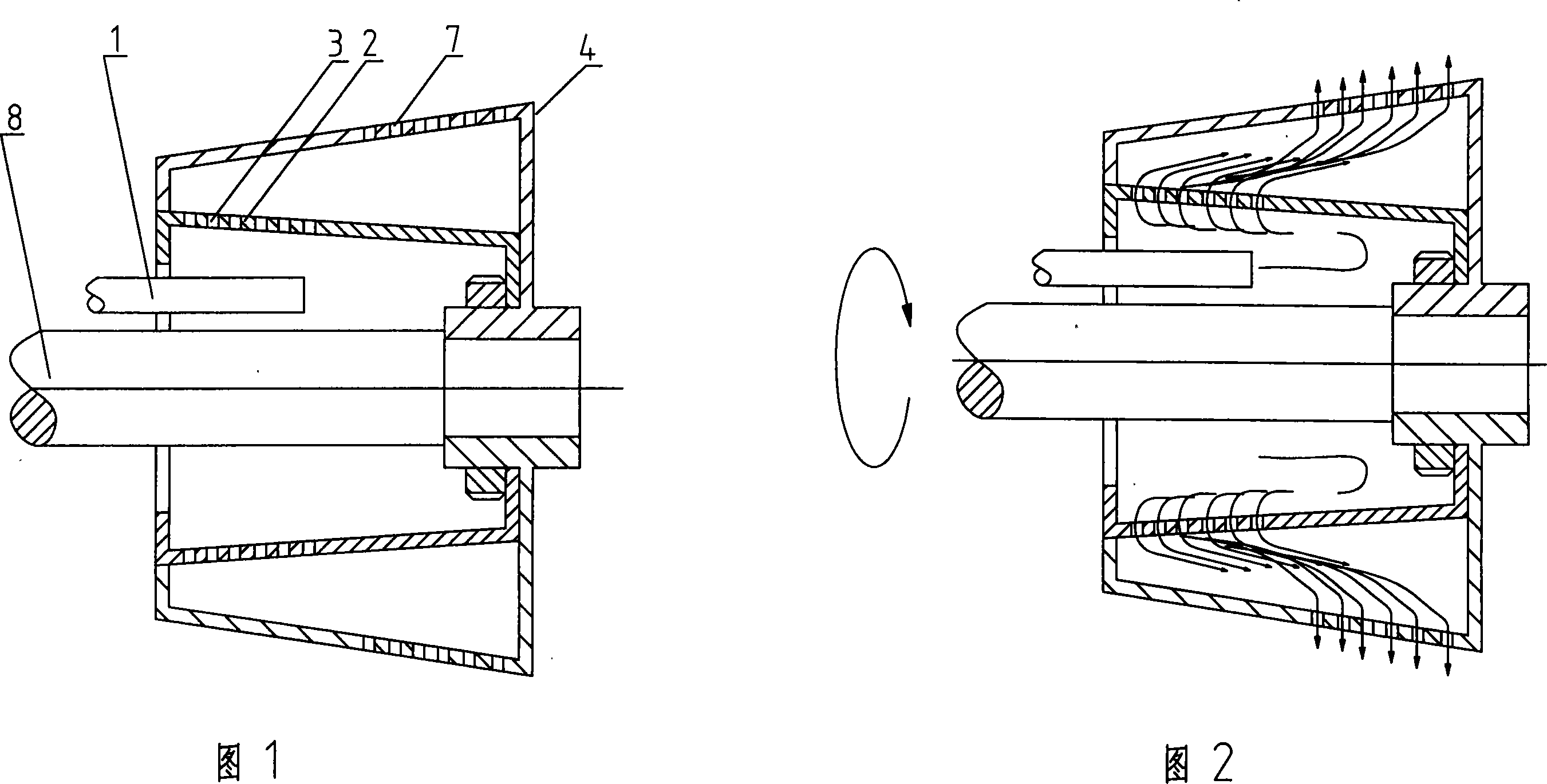

[0016] Example 1, as shown in Figure 1-2, the paint is injected into the inner rotating cup 2 through the feeding pipe 1, and the paint is evenly distributed in the inner rotating cup under the high-speed rotation of the motor shaft 8, and then sprayed out through the discharge micropores 3 on its surface , the paint enters the outer rotating cup 4, and the paint is evenly distributed in the outer rotating cup under the high-speed rotation of the motor shaft, and then sprayed out again through the discharge micropores 7 on the surface, so that the paint is sprayed on the inner wall of the steel pipe in a mist form, forming Uniform coating.

Embodiment 2

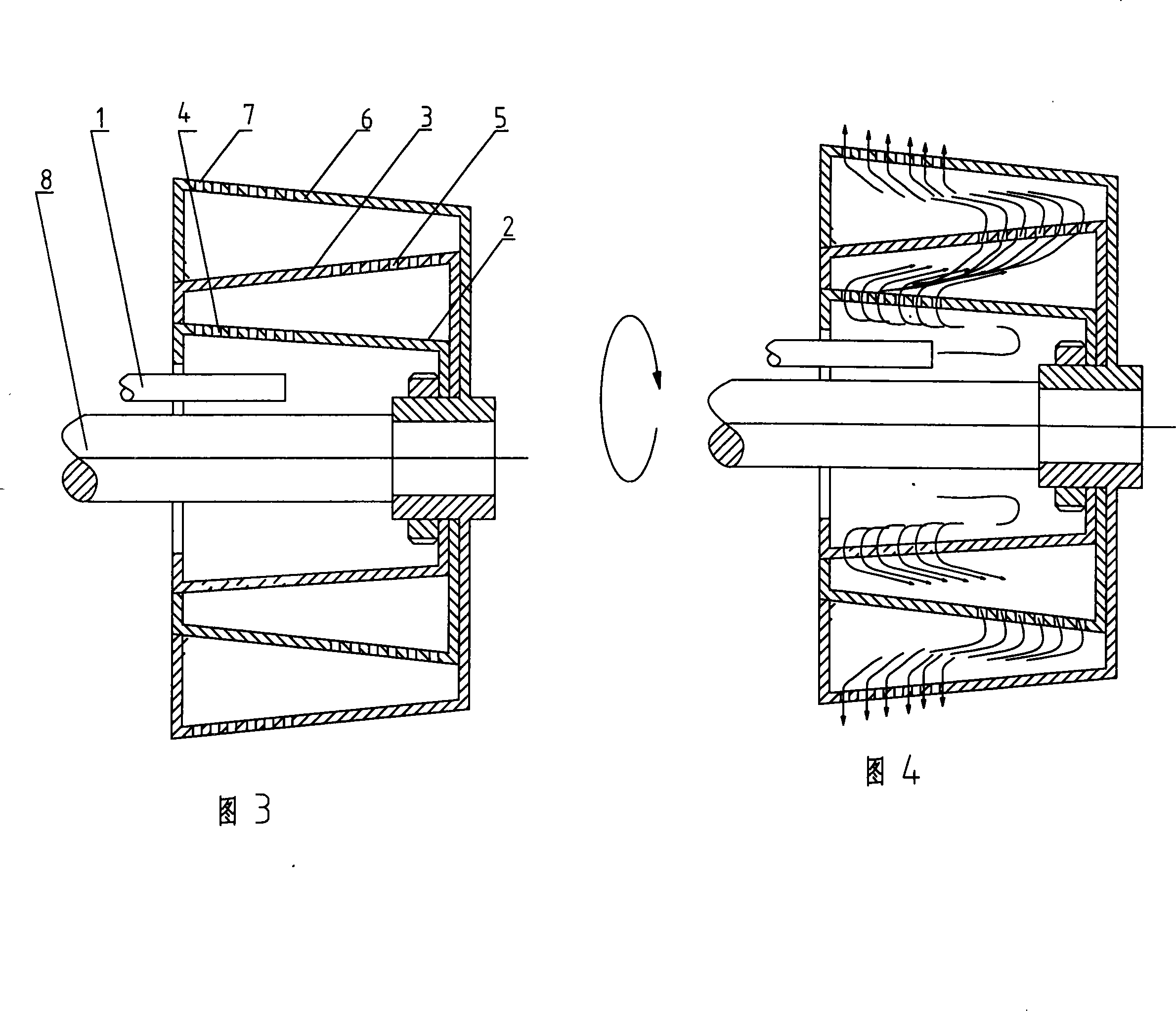

[0017] Example 2, as shown in Figure 3-4, is the working principle of the three-layer rotary cup: the paint is injected into the inner rotary cup 2 from the delivery pipe 1, and the paint passes through the surface of the inner rotary cup after the motor shaft 8 rotates at a high speed The discharge microholes 4 are sprayed into the middle rotary cup 3, and the paint is evenly distributed in the middle rotary cup 3 under the high-speed rotation of the motor shaft, and then sprayed out again into the outer rotary cup 6 through the discharge microholes 5 on its surface Under the high-speed rotation of the motor shaft, the paint is evenly distributed in the outer rotary cup 6 and then sprayed out again through the discharge micropores 7 on its surface, so that the paint is sprayed on the inner wall of the steel pipe in a mist form to form a uniform coating. When spraying, the paint is uniformly mixed and dispersed through the inner rotary cup cavity and then sprayed into the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com