Method and system for risk level evaluation of fuel gas polyethylene pipeline

A technology of risk level and evaluation method, which is applied in the field of level evaluation method and system, can solve the problems of non-applicability of risk evaluation method for gas polyethylene pipeline, influence on the accuracy of evaluation results, incompatibility with the development trend of gas polyethylene pipeline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

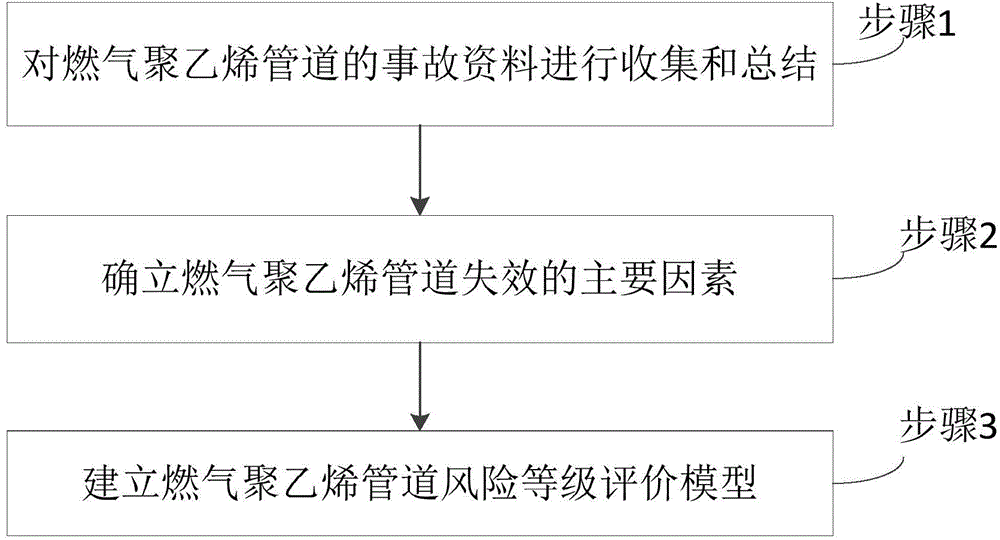

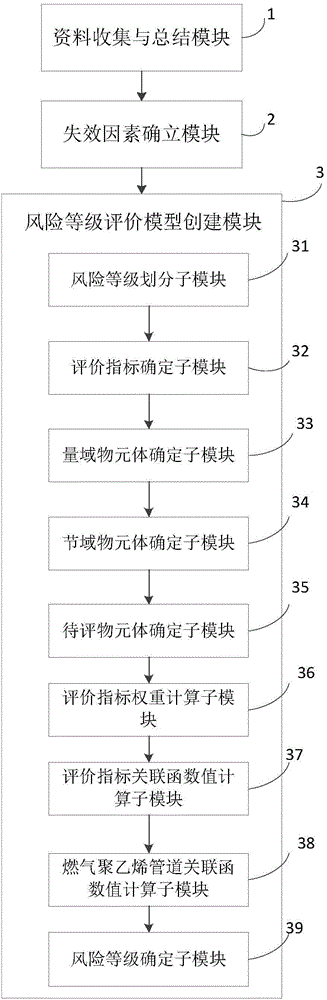

[0063] Such as figure 1 As shown, it is a flow chart of the gas polyethylene pipeline risk level evaluation method in the present invention, and the method includes the following steps:

[0064] Step 1. Collect and summarize the accident data of the gas polyethylene pipeline.

[0065] Step 2, establishing the main factors of failure of the gas polyethylene pipeline;

[0066] According to the American Plastics Pipeline Council and my country's in-service gas polyethylene pipeline accident statistics, the main factors of gas polyethylene pipeline accidents are determined to be: third-party damage, brittle cracking, creep failure, aging and leakage.

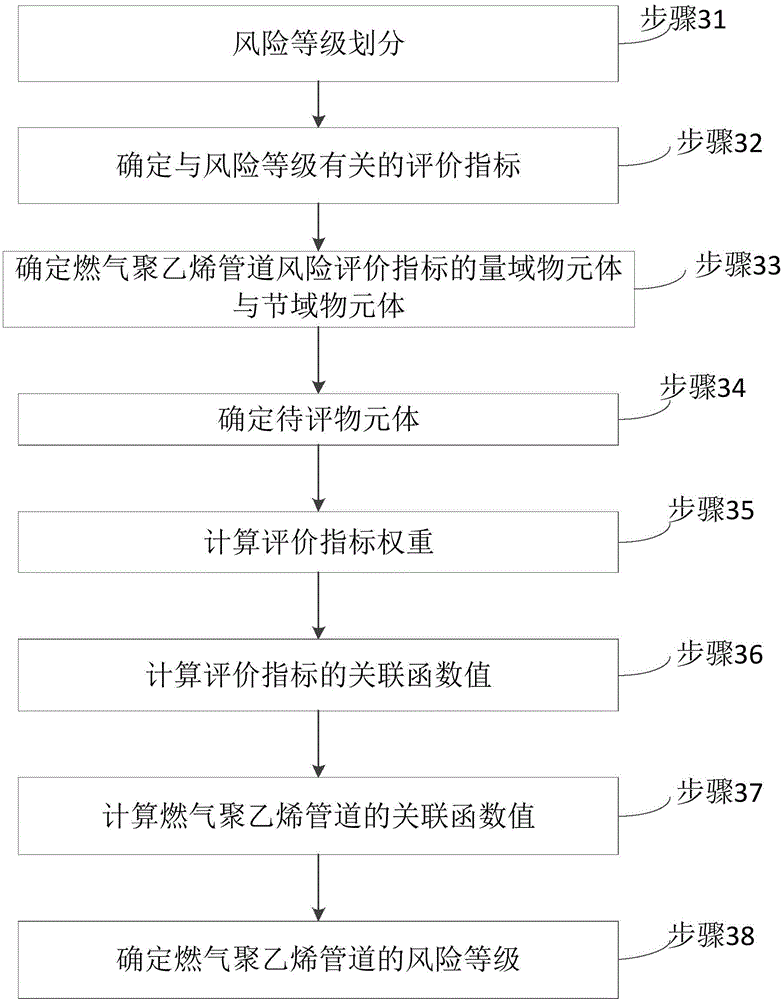

[0067] Step 3, establish the risk level evaluation model of the gas polyethylene pipeline, such as figure 2 As shown, it is a flow chart of step 3 in the gas polyethylene pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com