Cheese type honey product and preparation method thereof

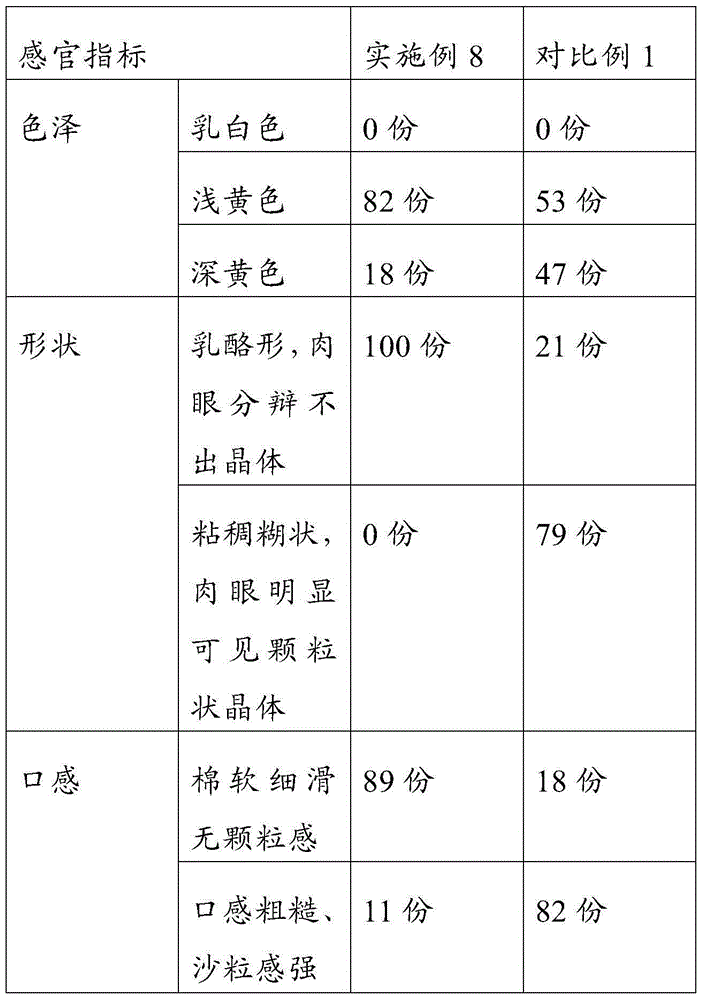

A technology of honey and cheese, which is applied in the field of food processing, can solve the problems of rough taste, inconsistent quality of cheese-like crystallized honey products, strong sandy feeling of cheese-like crystallized honey, etc., and achieve smooth taste, stable crystallization, and soft crystallization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of cheese-type honey product in the present embodiment, comprises the following steps,

[0028] (1) Mix natural wolfberry honey and milk vetch honey (mass ratio 1:1), filter through a 150-mesh filter, concentrate the filtrate to a water content of 15wt%, cool to 39°C to obtain liquid honey, and measure the The content of glucose in the liquid honey is 40.60wt%, the content of fructose is 32.92wt%;

[0029] (2) filling the liquid honey with compressed air until the liquid honey is filled with air bubbles to obtain the second liquid honey, the volume ratio of the liquid honey to the gas filled is 1:1;

[0030] (3) Put the second liquid honey in an environment of 12°C, and add glucose while stirring at a speed of 90r / min to obtain a honey mixture, wherein the amount of glucose added is 0.03g / g honey mixture (that is, every gram of honey mixture Glucose 0.03g was added in), so that after the glucose addition process was completed, when the water cont...

Embodiment 2

[0034] The preparation method of cheese-type honey product in the present embodiment, comprises the following steps,

[0035] (1) Filter the linden tree honey through a 180-mesh filter, concentrate the filtrate to a water content of 18wt%, cool to 29°C to obtain liquid honey, and determine that the content of glucose in the liquid honey is 35.82wt%, and the content of fructose is 35.82wt%. The content is 37.52wt%;

[0036] (2) filling the liquid honey with compressed air until the liquid honey is filled with air bubbles to obtain the second liquid honey, the volume ratio of the liquid honey to the gas filled is 2:1;

[0037] (3) Put the second liquid honey in an environment of 14°C, and add glucose while stirring at a speed of 50r / min to obtain a honey mixture, wherein the amount of glucose added is 0.1g / g honey mixture (that is, every gram of honey mixture Glucose 0.1g was added in), so that after the glucose addition process was completed, when the water content of the hone...

Embodiment 3

[0041] The preparation method of cheese-type honey product in the present embodiment, comprises the following steps,

[0042] (1) Filter the natural Vitex twig honey through a 200-mesh filter, concentrate the filtrate to a water content of 16wt%, and cool it to 35°C to obtain liquid honey, and determine the content of glucose in the liquid honey to be 33.94wt%, and the content of fructose The content is 36.90wt%;

[0043] (2) filling the liquid honey with compressed air until the liquid honey is filled with air bubbles to obtain the second liquid honey, the volume ratio of the liquid honey to the gas filled is 3:1;

[0044] (3) Put the second liquid honey in an environment of 13°C, and add glucose while stirring at a speed of 60r / min to obtain a honey mixture, wherein the amount of glucose added is 0.15g / g honey mixture (that is, every gram of honey mixture Glucose 0.15g was added in), so that after the glucose addition process was completed, when the water content of the hon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com