High efficiency red jujube coring machine capable of continuous transmission

A high-efficiency technology for red dates, which is applied in the fields of fruit de-pitting device, food science, application, etc., can solve the problems of low jujube loading rate, the conveyor belt cannot continuously feed materials and pitting efficiency, etc., and achieves the improvement of filling rate and pitting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

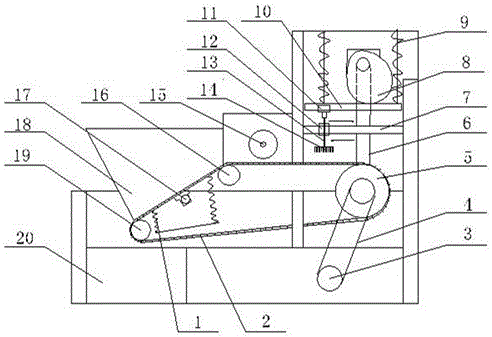

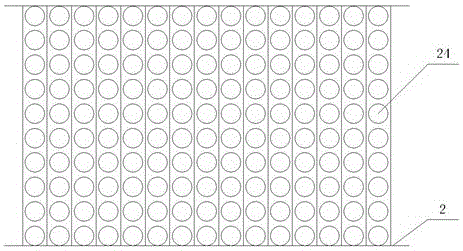

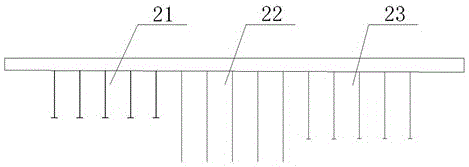

[0022] Such as figure 1 Shown, the efficient jujube pitting machine of continuous transmission comprises frame 20, and driving wheel, transition wheel 5, first driven wheel 16, second driven wheel 19 are installed on frame 20, and described second driven wheel 19 Located within the range of 25° to 35° on the lower left side of the first driven wheel 16, the first driven wheel 16 is located on the left side of the transition wheel 5, and the upper edge of the first driven wheel 16 and the upper edge of the transition wheel 5 are located on the same horizontal plane, A rolling device 16 is installed above the loading conveyor belt 2 between the first driven wheel 16 and the transition wheel 5, and the rolling device 16 is a roller, and the lowest point of the roller is at the height of the upper side of the conveying material. Less than jujube height; Driving wheel 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com