Explosion-proof dust collector and explosion-proof control method

A dust collector and control valve technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of no active fire extinguishing device, unfavorable safety production, dust collector explosion, etc., to eliminate potential safety hazards and increase safety. Reliability, eliminate the effect of secondary explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

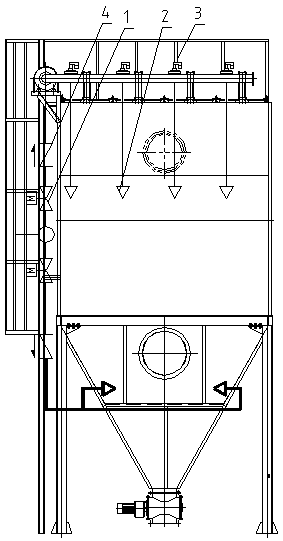

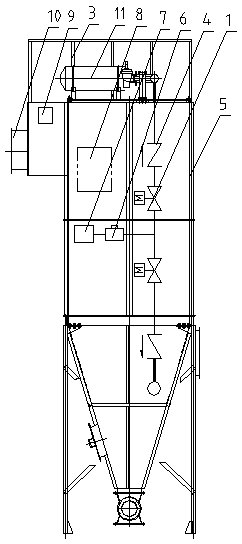

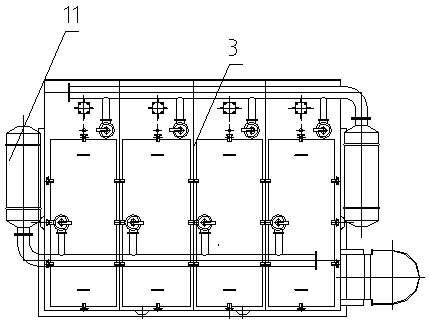

[0028] Such as Figure 1 to Figure 3 The shown explosion-proof dust collector includes a dust collector body 3 for collecting combustible dust, and the explosion-proof dust collector has a CO nozzle extending into the interior of the dust collector body 3. 2 Injection system; detection system for detecting CO concentration or / and temperature inside the dust collector body 3; controlling CO 2 Control system for the injection system. CO 2 The injection system includes two CO installed on the top of the dust collector body 3 2 Buffer tank 11, several through the pipeline respectively with CO 2 The control valve 1 connected to the buffer tank 11, several one-way valves 4 connected to each control valve 1 through pipelines, and several inerting valves respectively located on the top or bottom of the dust collector body 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com