Automatic take-out method and mechanical arm based on cam mechanism

A technology of robotic arms and cam guide rails, applied in container manufacturing machinery, transportation and packaging, paper/cardboard containers, etc., can solve problems such as being unsuitable for large-scale industrial production, difficult to maintain and repair, affecting aesthetics, etc., to achieve easy upgrades and maintenance. , long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

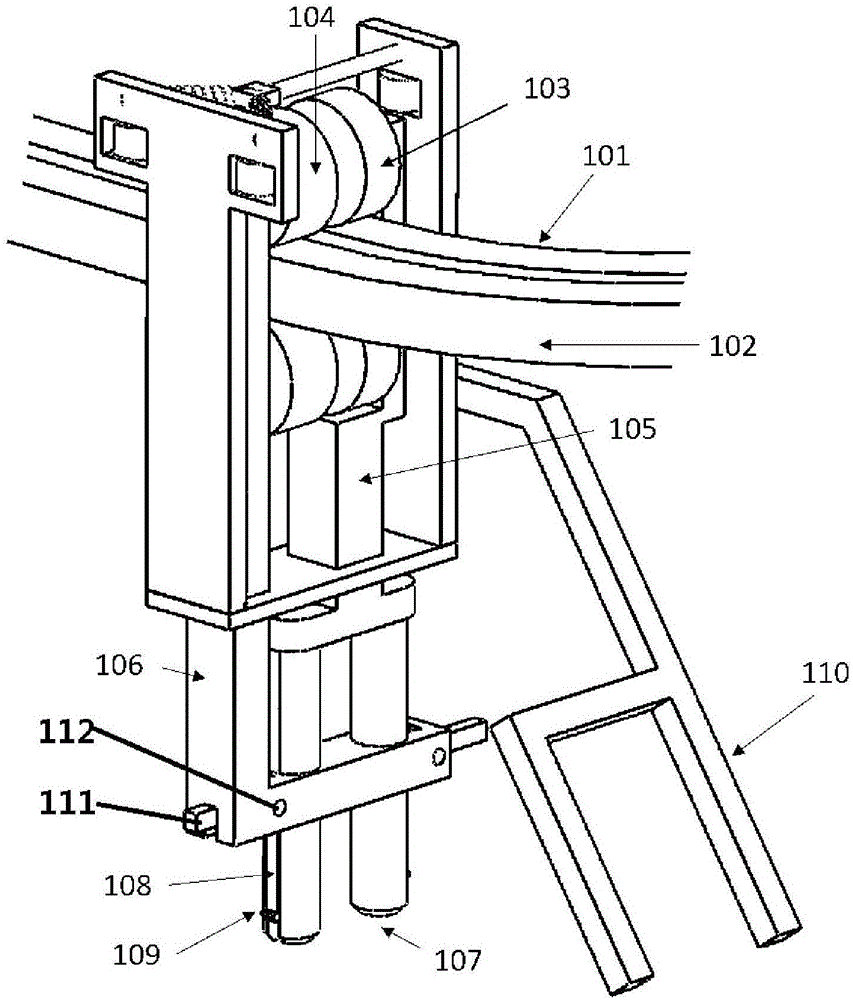

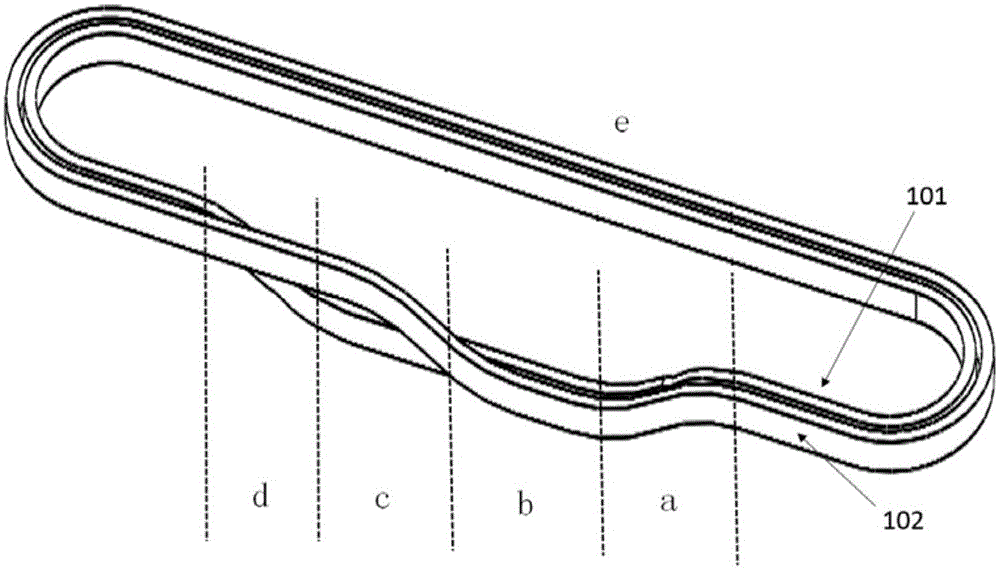

[0026] Such as Figure 1-2 As shown, the model taking mechanical arm mechanism includes guiding components: a first cam guide rail 101 and a second cam guide rail 102; positioning components for positioning: a first cam roller 103, a first driven rod 105, one or more guide rails Post 107 and pushing part 110, have straight groove 108 on this one or more guiding post 107; The part that is used to take the impression of taking impression action: the second cam roller 104, the second follower rod 106 and barb 109, The barb 109 is connected with the second driven rod 106 and can move with it, and can be received in the straight groove 108 of the guide column 107 under the action of the spring. One end of the pushing member 110 is mounted on the first follower rod 105 through a hinge, and the pushing member 110 is maintained at the maximum upward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com