Blade spring structure made of composite materials and equal in sectional area

A composite material plate and cross-sectional area technology, applied in leaf springs, springs/shock absorbers, elastic suspensions, etc., can solve the problems of high cost and high environmental pollution risk, and achieve significant lightweight and weight reduction effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

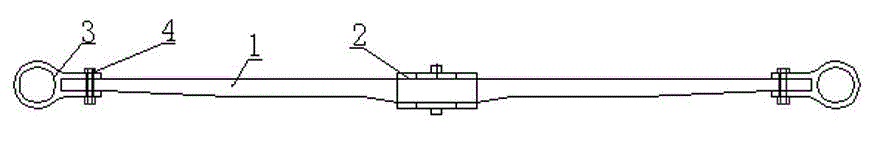

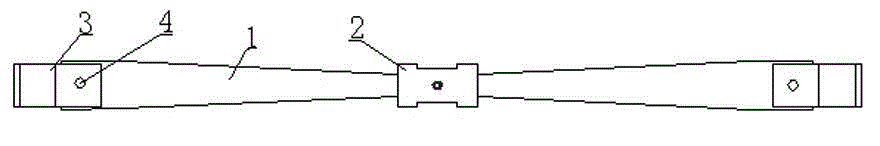

[0017] The present invention as figure 1 , 2 shown.

[0018] A composite material leaf spring structure of equal cross-sectional area, including a composite material leaf spring body 1, the composite material leaf spring body 1 part is gradually widened along the length direction from the middle to both ends; the thickness gradually becomes thicker Thin so that its cross-sectional area is always equal.

[0019] The middle part of the composite leaf spring body 1 is fixedly connected to the composite leaf spring body 1 by a clamp 2 structure; the lifting lugs 3 are fixedly connected at both ends by bolts and nuts 4 and glued.

[0020] The composite material leaf spring assembly is composed of a composite material leaf spring main body 1, an intermediate clamp structure 2, lifting lugs 3, and bolts and nuts 4 to form an assembly.

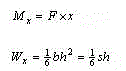

[0021] The cross-sectional area of the composite leaf spring body 1 along the length direction is equal everywhere; and according to the stress ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com