Preparation method of composition-controlled directional crystallization of near-stoichiometric lithium niobate crystals

A near-stoichiometric, directional crystallization technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as poor symmetry, stay, and no industrialized production, and achieve low crystal dislocation density and energy. The effect of reducing energy consumption and stabilizing the growth environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

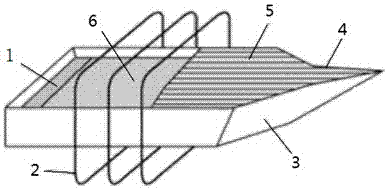

[0048] Example 1: N-SLN crystal

[0049] Weigh a portion of Li with a Li / Nb molar ratio of 58.5 / 41.5 2 CO 3 and Nb 2 o 5 90g of high-purity powder raw material, and then weighed a Li / Nb molar ratio of 50 / 50 Li 2 CO 3 and Nb 2 o 5 Powder raw material 1950g. Mix these two kinds of powder raw materials in a mixer for 10 hours, then press them into cakes with a mold, then put the cakes into rectangular Pt crucibles, and pre-fire them in a muffle furnace at 1250°C for 2 hours. melts and emits CO 2 After cooling, a polycrystalline pre-crystallization material is formed, and the size of the pre-fired crucible is the same as that of the equal width part of the crystal growth crucible, which is 300mm×60mm×30mm. The prepared pre-crystal material is loaded into the alcohol-washed boat-shaped Pt crucible, the proportion of the pre-crystal material placed on the shoulder is 58.5 / 41.5 (Li / Nb molar ratio), and the pre-crystal material placed in the equal width zone is The proportio...

Embodiment 2

[0050] Example 2: N-SLN crystal doped with MgO

[0051] Weigh a portion of Li with a Li / Nb molar ratio of 58.5 / 41.5 2 CO 3 and Nb 2 o 590g of high-purity powder raw material, and add 0.42g of high-purity MgO raw material; then weigh a Li / Nb molar ratio of 50 / 50 Li 2 CO 3 and Nb 2 o 5 Powder raw material 1950g, and add high-purity MgO raw material 9.3g. Mix these two kinds of powder raw materials in a mixer for 10 hours, then press them into cakes with a mold, then put the cakes into rectangular Pt crucibles, and pre-fire them in a muffle furnace at 1250°C for 2 hours. melts and emits CO 2 After cooling, a polycrystalline pre-crystallization material is formed, and the size of the pre-fired crucible is the same as that of the equal width part of the crystal growth crucible, which is 300mm×60mm×30mm. The prepared pre-crystal material is loaded into the alcohol-washed boat-shaped Pt crucible, the proportion of the pre-crystal material placed on the shoulder is 58.5 / 41.5 ...

Embodiment 3

[0052] Example 3: CLN crystal

[0053] Weigh the Li / Nb molar ratio of 48.6 / 51.4 Li 2 CO 3 and Nb 2 o 5 Put 2050g of high-purity powder raw material into a mixing tank and mix for 10 hours, then press it into a cake with a mold, then put the cake into a Pt boat-shaped crucible, pre-fire it in a muffle furnace at 1280°C for 2 hours, and melt the raw material and discharge CO 2 After cooling, a polycrystalline pre-crystallization material is formed. The size of the pre-fired crucible is exactly the same as that of the crucible used for crystal growth, which is 330mm×60mm×30mm. Put the boat-shaped crucible filled with pre-crystallization material in the furnace, and put the heat preservation porcelain, and heat up after closing the furnace. When the temperature in the high temperature zone rises to ~1250°C, the liquid flow line of the melt is observed, and the heating power is properly adjusted to make the solid-liquid transformation phenomenon of orderly convection just appe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com