A vehicle track changing device

A technology for locomotives and carriages, applied in the field of on-board rail changing devices for railway engineering vehicles, which can solve the problems of high labor intensity for operators, inability to operate flat cars, and high maintenance costs, and achieve the effects of reasonable design structure, rapid replacement, and maintenance safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

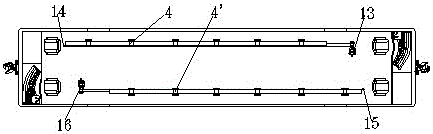

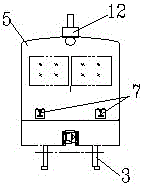

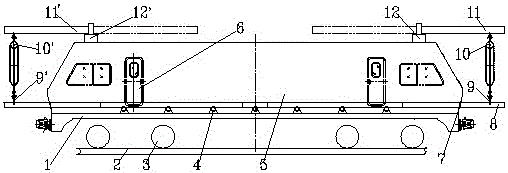

[0018] given in the present invention figure 1 , figure 2 , image 3 In the shown embodiment, the locomotive car 5 is installed and fixed on the locomotive chassis 1, and the power unit is installed on the locomotive chassis 1 (in the car), and the wheelset 3 installed under the locomotive chassis 1 is located on the track 2, and the two ends of the car are respectively A cab and a locomotive control mechanism are provided, and doors 6 are respectively provided on the front and rear sides of the compartment; the first row of guide wheel devices 4 and the second row of guide wheel devices 4' with the same structure are respectively provided on both sides of the locomotive chassis 1 in the compartment; On the car body of the front of the first row of guide wheel devices 4 and the two ends of the second row of guide wheel devices 4', rail inlets and outlets 7 are respectively provided; On the first row of guide wheel devices 4 and the second row of guide wheel devices 4'.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com