In-situ heat regeneration device for layered heating, raking and moving mixed asphalt pavement

A technology of asphalt pavement and regeneration device, which is applied in the direction of roads, roads, road repairs, etc. It can solve the problems of a large amount of asphalt smoke, uneven heating, fuel waste, etc., and achieve the effects of improved heating efficiency, uniform heating, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

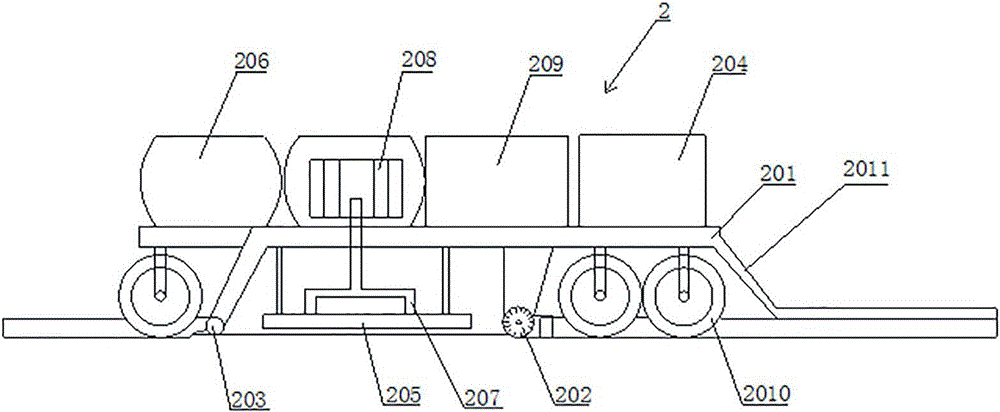

[0027] With reference to the accompanying drawings, an in-situ thermal regeneration device for layered heating, raking and moving mixing asphalt pavement includes a first heating machine 1 , a second heating machine 2 and a regenerative mixing paver 3 . The first heating machine 1, the second heating machine 2 and the regenerative mixing paver 3 are continuously working together in sequence, such as Figure 7 shown.

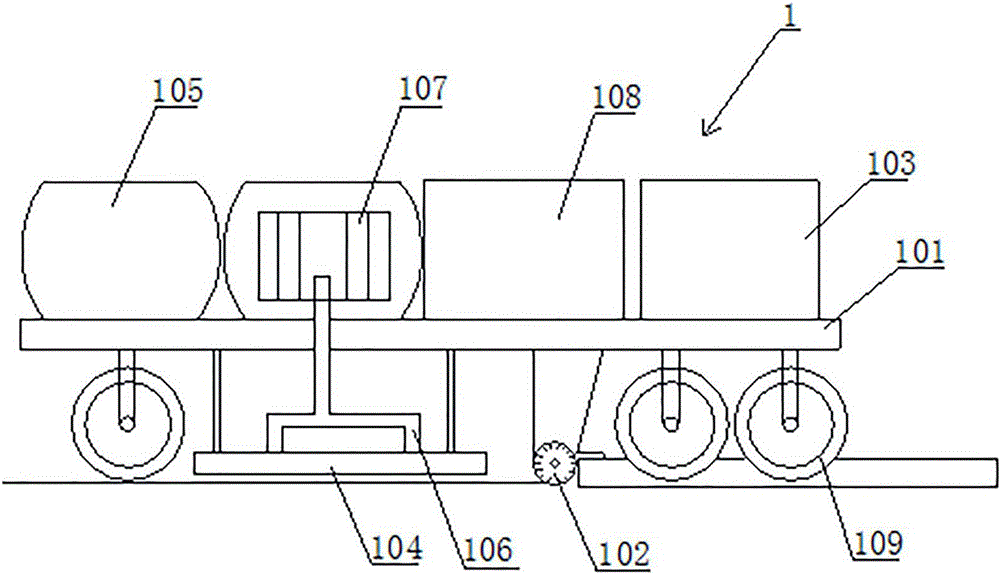

[0028] Such as figure 1 As shown, the first heating machine 1 includes a vehicle body 101 on which a heating device, a raking device 102 , a power traveling device and an operating system 103 are installed. The heating device includes a heating plate 104 and a heating fuel chamber 105 , and the heating fuel chamber 105 is used for transferring heat to the heating plate 104 . The heating plate 104 is installed at the middle and lower part of the vehicle body, a smoke and dust conveying pipe 106 is arranged above the heating plate 104 , and a smoke and dust proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com