Separable hydraulic sliding sleeve for oil and gas wells

A hydraulic sliding sleeve and separation technology, which is used in wellbore/well components, wellbore/well valve devices, and production fluids, etc., can solve the problem of not being able to separate the tubing from the completion tool, and achieve simple structure and high performance. Reliable and easy-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

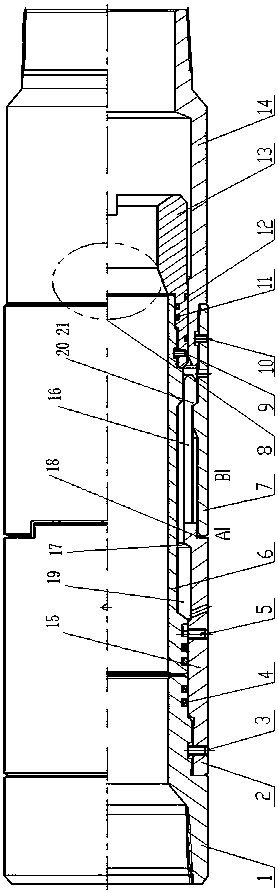

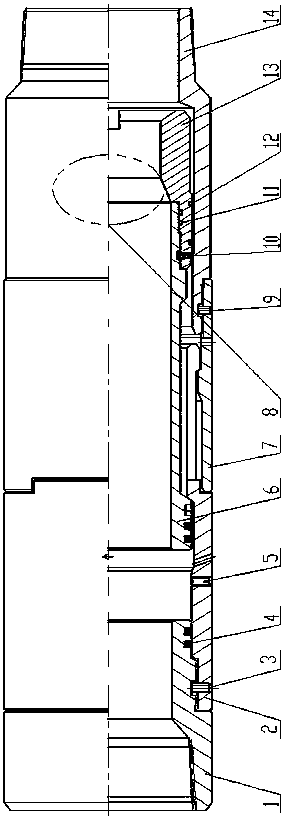

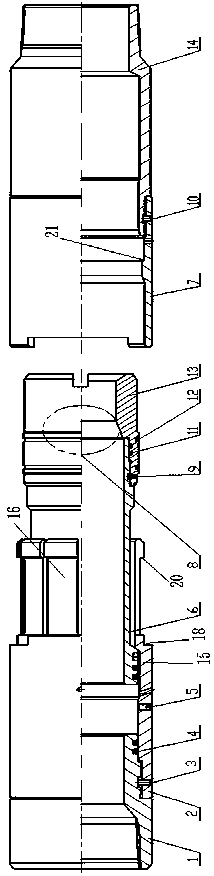

[0030] With reference to the drawings in the description, as the most basic embodiment of the present invention, it includes an upper joint 1, a lower joint 14, a ball seat 13, a throwing claw 2, an anti-rotation connecting cylinder 7 and a limit tube 6. The upper joint 1 It is fixedly connected with the throwing claw 2; the ball seat 13 and the limit tube 6 are fixedly connected to form a moving part, and is fixed in the inner cavity of the throwing claw 2 by a safety shear nail 5; the throwing claw 2 It includes a hollow cylindrical segment 15 and a claw segment 16 surrounded by a plurality of claw pieces. The hollow cylindrical segment 15 and the claw segment 16 are connected as one and formed with an upper step 17 and a lower step 18. The anti-rotation connection One end of the barrel 7 is fixedly connected to the lower joint 14, and the other end of the anti-rotation connecting barrel 7 is fastened to the lower step 18 formed between the hollow cylindrical section 15 and t...

Embodiment 2

[0033] On the basis of the above embodiments, the best implementation mode of the present invention is that the upper end of the claw slope 20 is inclined towards the end of the upper joint 1 . The upper joint 1 is fixedly connected with the throwing claw 2 by threads, and is fixed by set screws. The ball seat 13 is fixedly connected with the limit tube 6 through threads, and is fixed by set screws. The anti-rotation connecting cylinder 7 is fixedly connected with the lower joint 14 by threads, and fixed by set screws. Between the throwing claw 2 and the upper joint 1, between the throwing claw 2 and the limit tube 6, between the limit tube 6 and the ball seat 13, and between the ball seat 13 and the lower joint 14, there are At least one sealing ring. The other end of the anti-rotation connecting cylinder 7 is fastened to the lower step 18 formed between the hollow cylindrical section 15 and the claw segment 16 through the anti-rotation pin and the anti-rotation groove. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com