Improved structure of engine oil-gas separator

A technology of oil-gas separator and oil-gas separation chamber, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., which can solve the problems of inability to meet higher emission limit requirements, complete vehicles that cannot be sold on the market, and bloated layout, etc., to achieve improved Oil and gas separation effect, beneficial to landing, and beneficial to collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

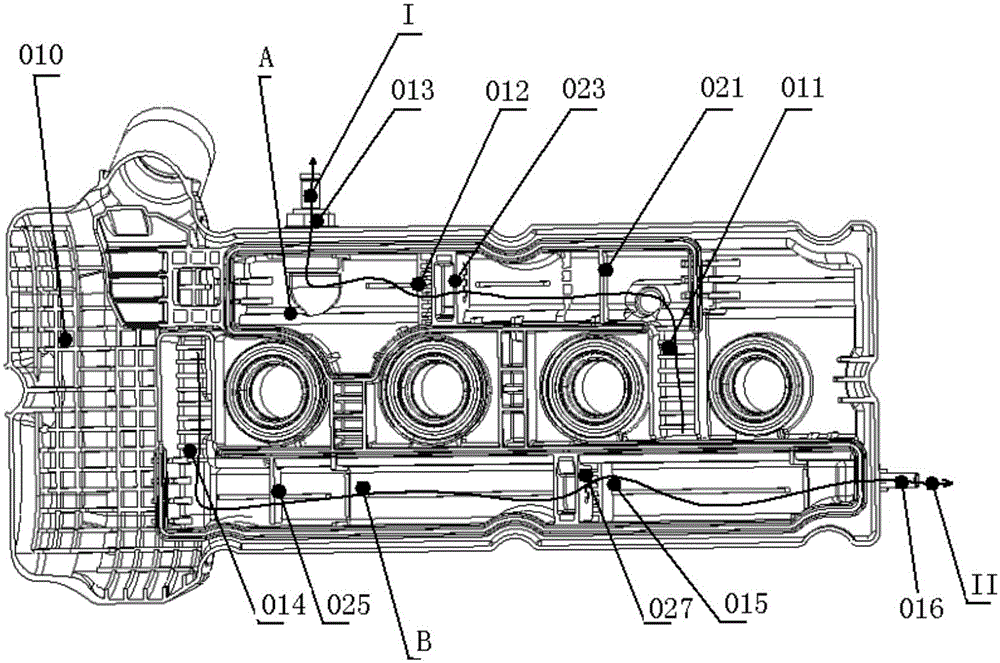

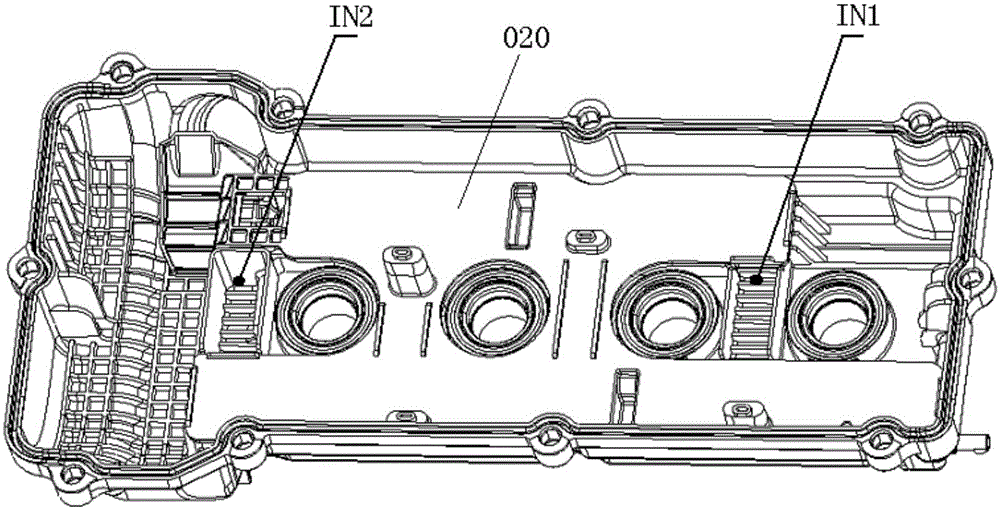

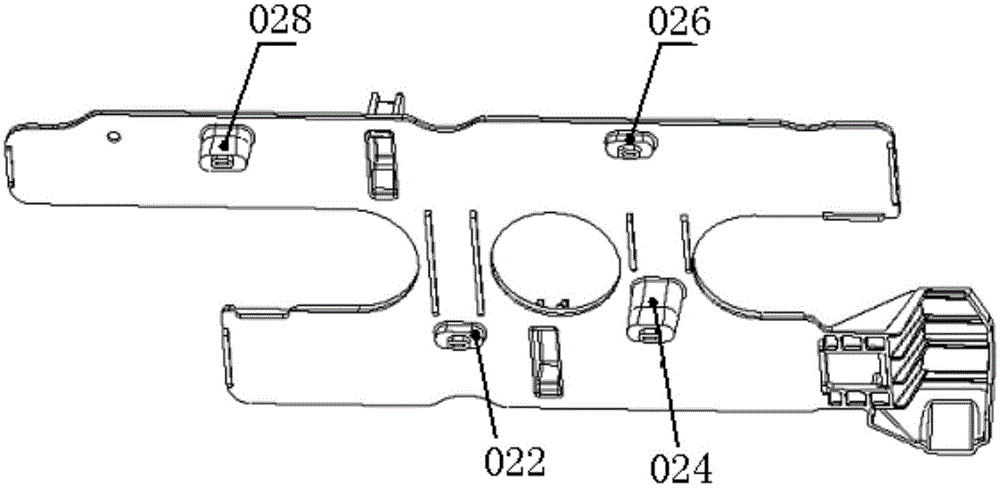

[0049] The invention provides an improved structure of an engine oil-gas separator, such as Figure 6 to Figure 11 As shown, a cylinder head guard 100 is included, and an oil-air separation chamber is arranged on the inner surface of the cylinder head guard 100; the cylinder head guard in this application refers to a cylinder head guard integrated with an oil-gas separator, not Includes cylinder head guards without integrated air separator. In the technical solution of the present application, it is only related to the structure of the oil-air separator on the cylinder head guard, while other structures arranged on the cylinder head gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com