Inerter capable of adjusting inertance coefficient

A technology of inertial coefficient and inerter, which is applied in the field of vibration-absorbing devices, can solve problems such as difficulty in obtaining vibration-reducing effects, and achieve the effect of simple structure and strong working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

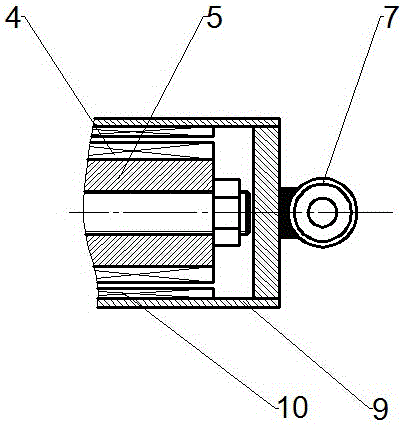

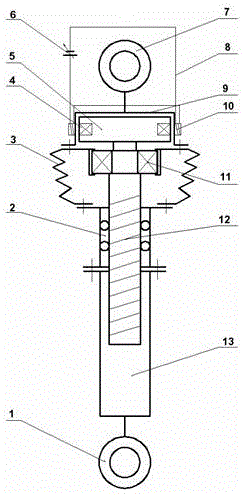

[0032] An inerter with an adjustable coefficient of inertia, the structure of which is as follows figure 1 As shown, it includes upper lifting lug 7, flywheel chamber 9, flywheel 5, leading screw 12, stroke chamber 13, leading screw nut 2, lower lifting lug 1.

[0033] The upper lug 7 is connected with the upper end of the flywheel chamber 9 .

[0034] The periphery of the flywheel chamber 9 is provided with a stator coil 10 electrically connected to the power supply 6 via a wire 8 . The stator coil 10 has an annular structure, and the axis of the stator coil 10 is parallel to the axis of the lead screw 12 . The magnitude and direction of the current generated when the stator coil 10 is energized is controlled by the power supply 6 .

[0035] The flywheel 5 is located in the flywheel chamber 9 , and the periphery of the flywheel 5 is provided with a rotor coil 4 that can rotate with the flywheel 5 . The rotor coil 4 has a ring structure, and the axis of the rotor coil 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com