Gear shifting control method and device for gear box of loading machine, electric control system and loading machine

A control method and technology of a control device, which are applied in the direction of transmission control, mechanical equipment, components with teeth, etc., can solve problems such as fuel consumption, and achieve the effect of improving power use efficiency, ensuring power performance, and facilitating production management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

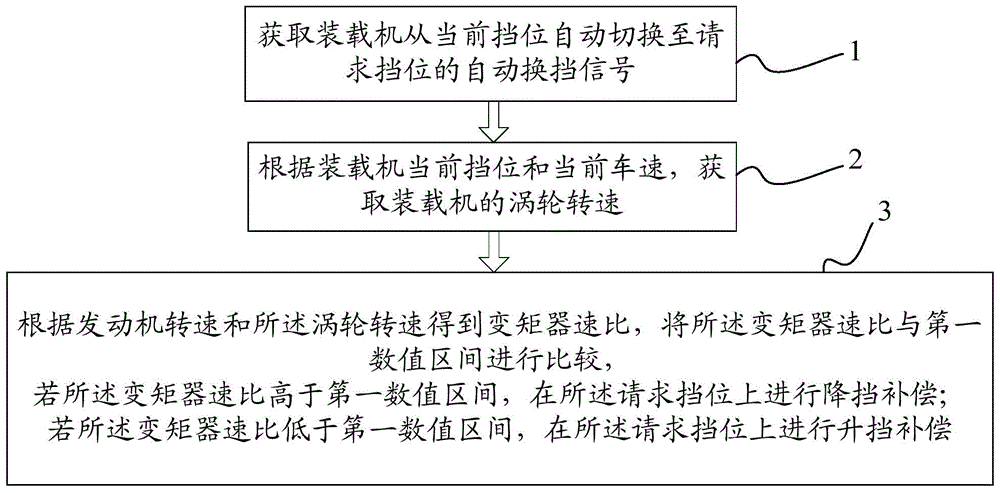

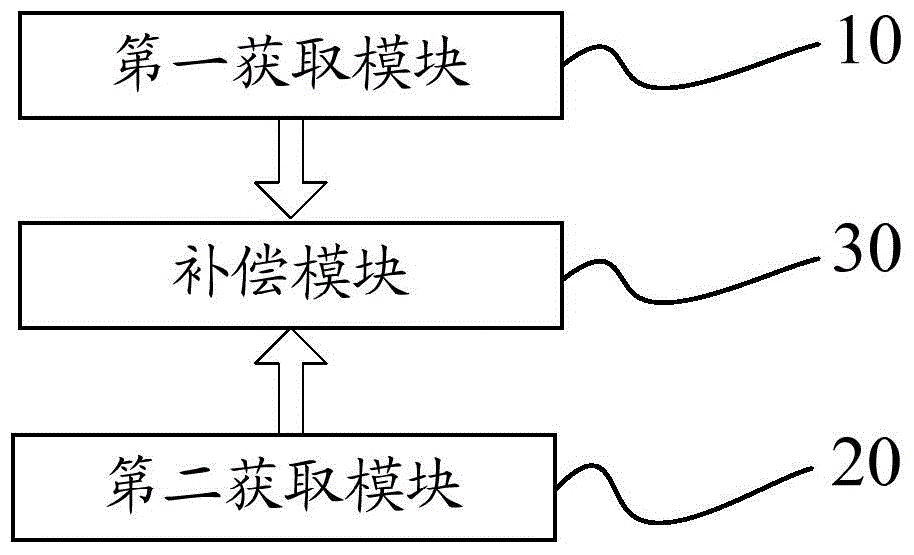

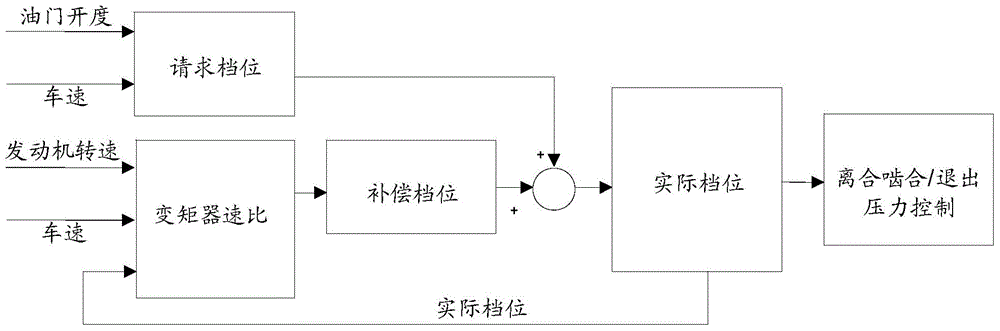

[0061]The present invention provides a gear shift control method for a loader gearbox, comprising: acquiring an automatic gear shift signal for the loader to automatically switch from the current gear to the requested gear; Turbine speed: get the torque converter speed ratio according to the engine speed and the turbine speed, compare the torque converter speed ratio with the first value range, if the torque converter speed ratio is higher than the first value range, then Perform down-shift compensation on the requested gear; if the torque converter speed ratio is lower than the first value range, perform up-one gear compensation on the requested gear.

[0062] refer to figure 1 Generally speaking, the loader gearbox shift control method of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com