Fiber grating displacement sensor with temperature measuring function for marine engineering

A displacement sensor and fiber grating technology, applied in the field of displacement measurement devices, can solve the problems of easy corrosion damage, low survival rate of vibrating wire displacement sensor, affecting test results, etc., so as to improve measurement efficiency and accuracy, and achieve stable and reliable work performance. , the effect of simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

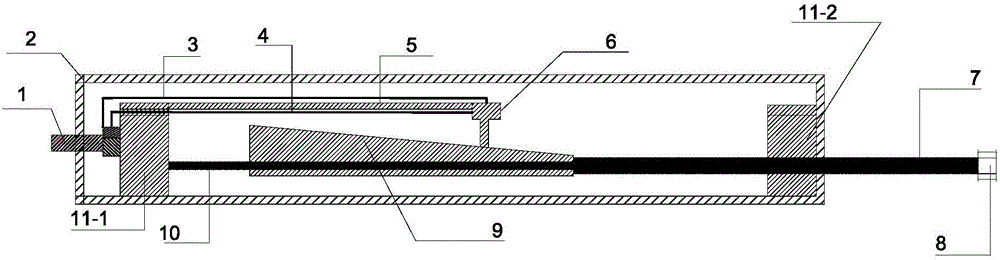

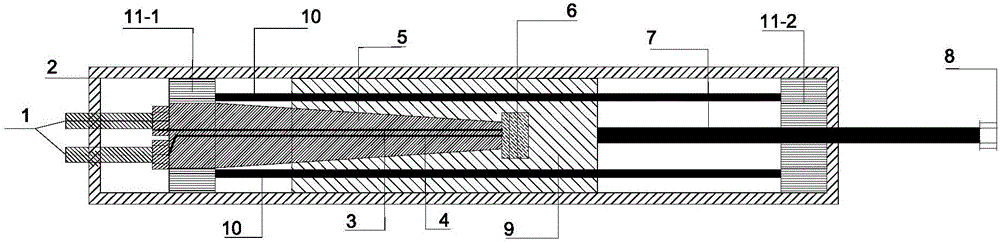

[0014] See Figure 1 ~ Figure 3 , A fiber grating displacement sensor with temperature measurement function for marine engineering, comprising a housing 2 in which a front support block 11-2 and a rear support block 11-1 are provided. Between the front support block 11-2 and the rear support block 11-1 are two guide rails 10 fixed to them, and the guide rails 10 are parallel to the longitudinal center line of the housing 2; A ramp slider 9 is installed on the guide rail 10, and a contact piece 6 is provided above the slope surface of the ramp slider 9, and the contact piece 6 is fixed at the front end of the equal-strength beam 5. 6 Always maintain stable and reliable surface contact with the slope surface of the slope slider 9. The equal-strength beam 5 is parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com