Universal testing machine tension-compression integrated experimental fixture

A universal testing machine and fixture technology, which is applied in the field of material mechanics and performance research, can solve the problems of inability to realize axial load alignment, inability to realize tension and compression experiments, and large friction in experiments, so as to achieve simple structure, ensure accuracy, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

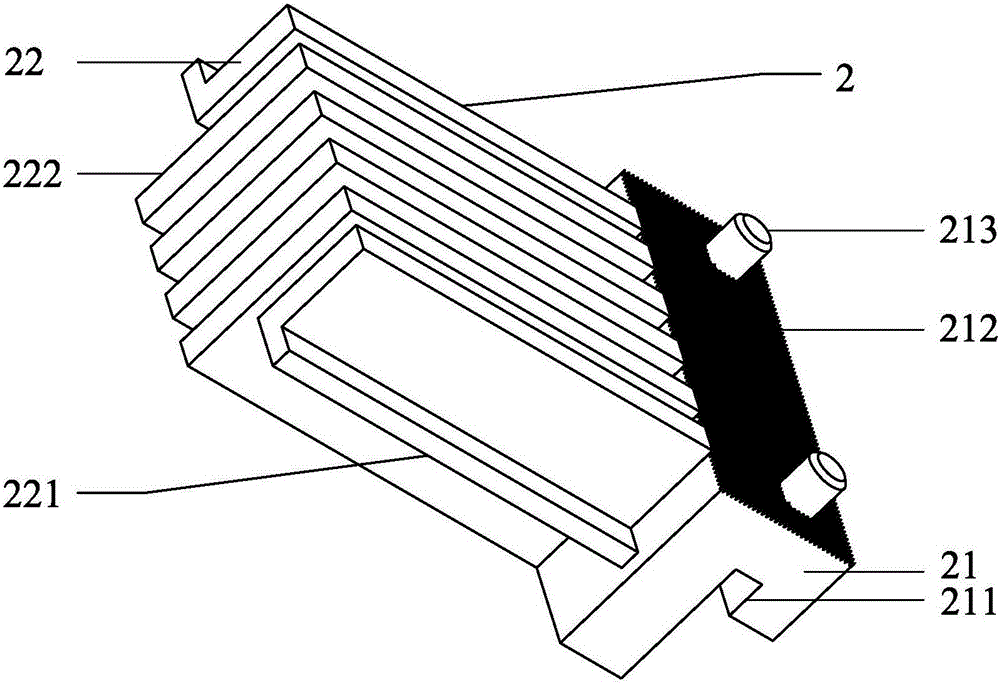

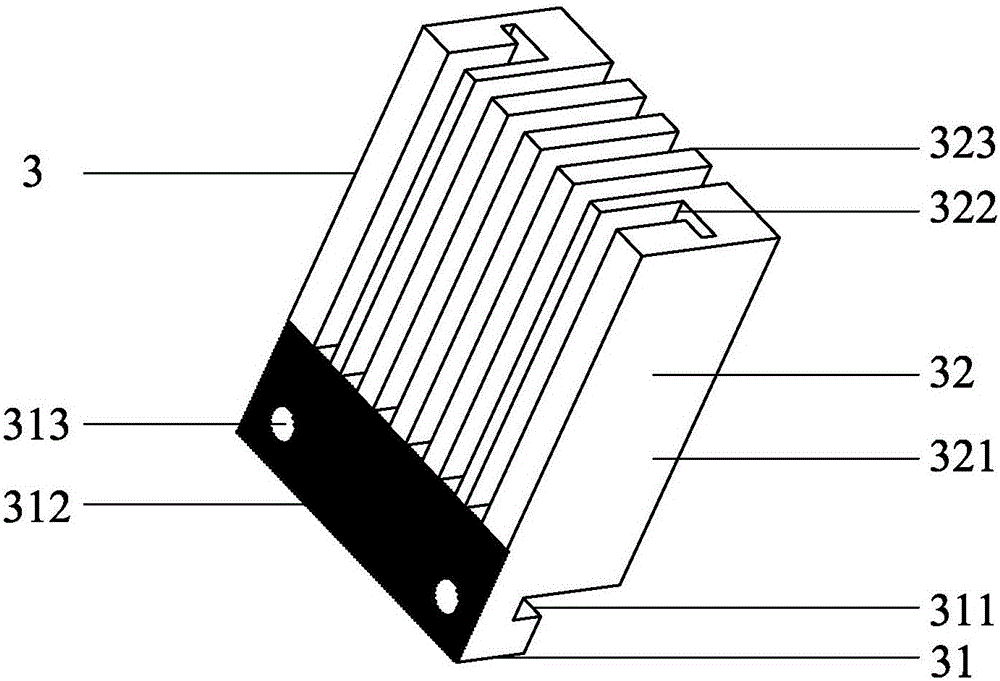

[0037] Such as Figure 6 As shown in Fig. 1, a tensile and compression integrated test fixture for a universal testing machine includes upper fixture Ⅰ1, upper fixture Ⅱ3, lower fixture Ⅰ2 and lower fixture Ⅱ4. processed separately.

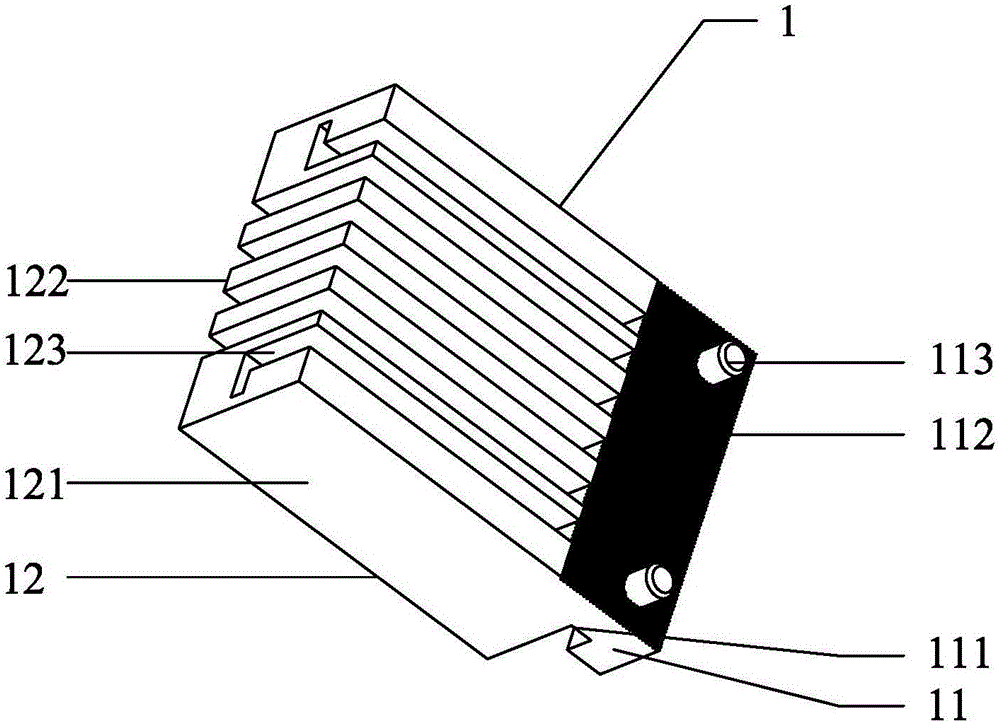

[0038] Such as figure 1As shown, the upper fixture I1 includes an upper end part I11 and an upper guide base part I12 arranged on the upper end of the upper end part I11. The upper guide base part I12 includes guide positioning parts I121 arranged on both sides and arranged on two A plurality of upper comb-shaped guide rail columns I122 between the guide positioning parts I121, the guide positioning part I121 is provided with a positioning groove I123, the positioning groove I123 is an "L"-shaped rail groove, and the "L"-shaped rail groove is only One of the preferred embodiments of the present invention, in the actual processing process, can be designed according to actual needs as long as the rail groove form meets the strength and use requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com