Oil-immersed 54 pulse wave frequency conversion transformer for large-power high-voltage frequency conversion apparatus

A frequency conversion transformer, high voltage frequency conversion technology, applied in the direction of transformer, transformer/inductor coil/winding/connection, inductor, etc., can solve the problems of high difficulty, large space and complexity, and achieve strong short-circuit resistance and structure. Reasonable, base-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

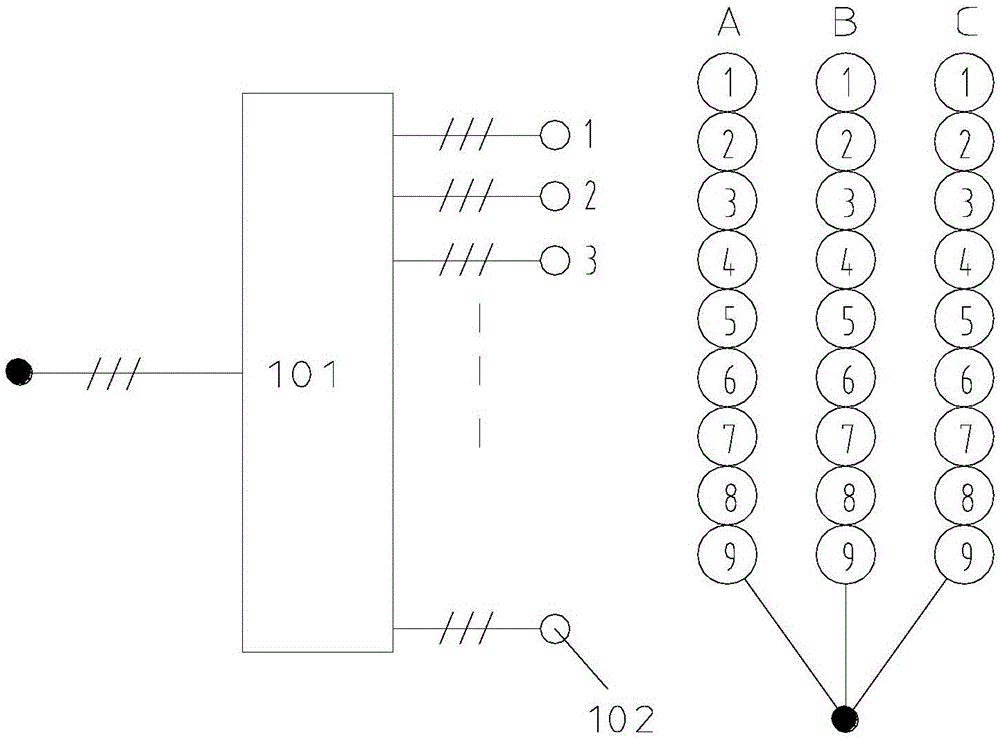

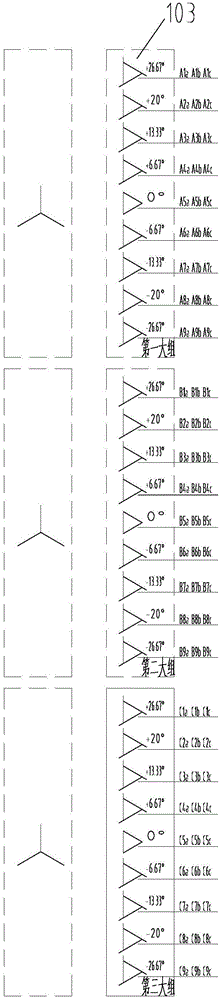

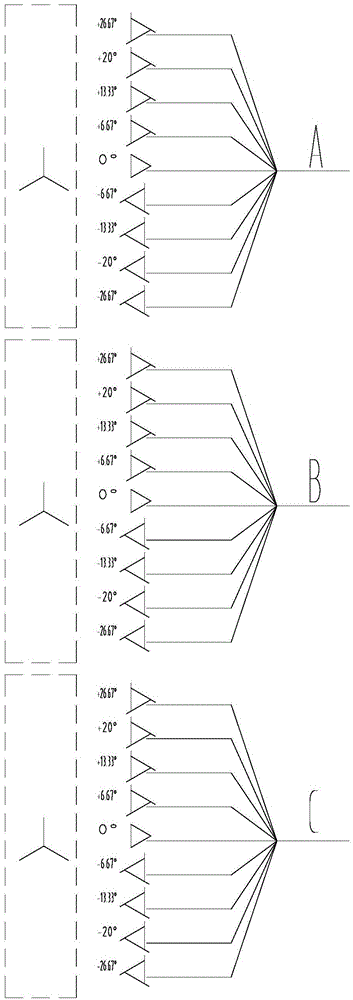

[0026] See Figure 4 , is a structural schematic diagram of the present invention, an oil-immersed 54-pulse frequency conversion transformer 101 for a high-power high-voltage frequency conversion device of the present invention, a three-phase input winding with a Y-shaped connection for high voltage, and a multi-phase output with a delta connection for low voltage Windings, low-voltage windings are divided into three large groups, each of which includes 9 phase-shifted windings, and their phase-shifted angles are +26.67°, +20°, +13.33°, +6.67°, 0°, -6.67° , -13.33°, -20°, -26.67°, the angle difference of each phase-shifting winding is 6.67°; each phase is composed of several power units 102 connected in series, and the difference between adjacent three-phase low-voltage outputs is 6.67°, the nine The phase-shifting winding 104 is controlled by th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap