Cage portion and method for the production thereof

A cage and section technology, applied in the direction of rotating parts, bearings, bearing components, etc. that resist centrifugal force, can solve the problem of high manufacturing cost of the cage and achieve the effect of stabilizing the connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

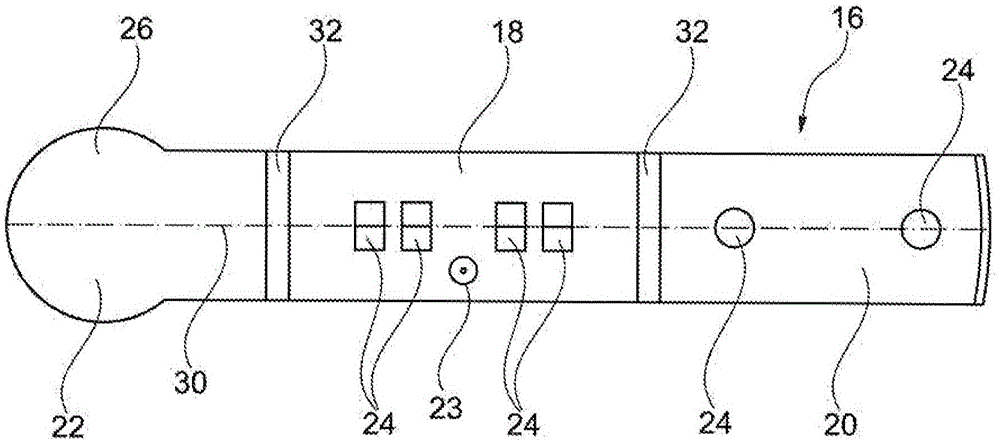

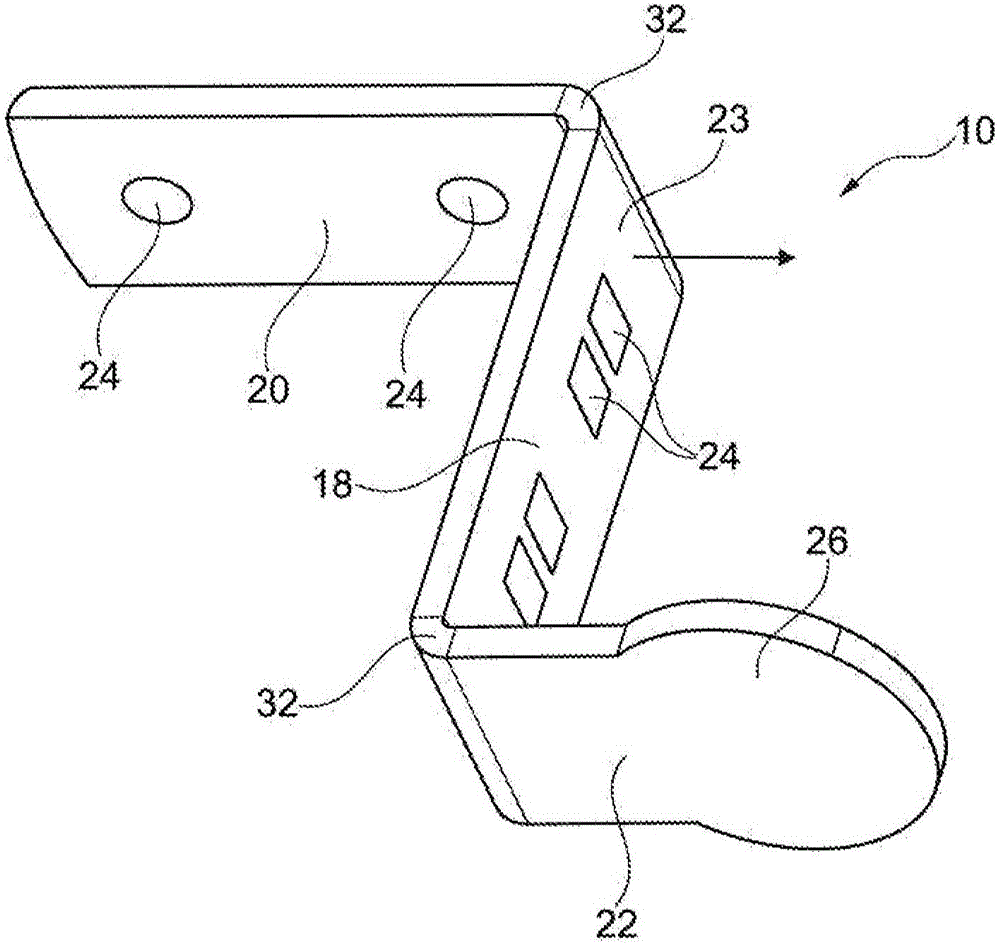

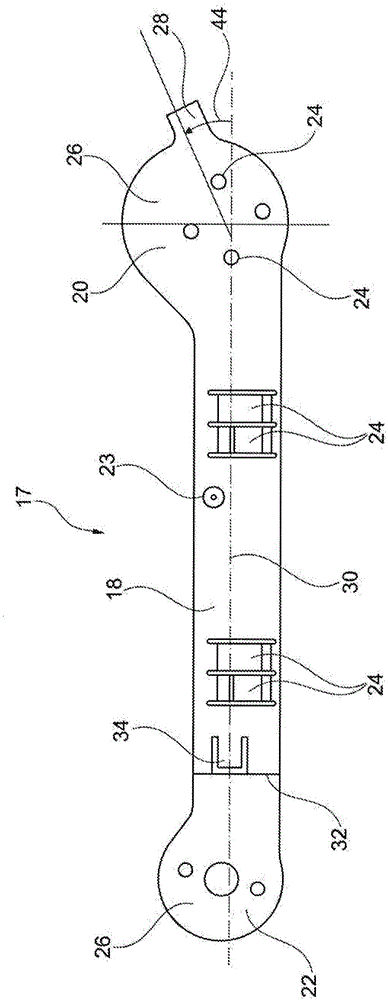

[0031] figure 1 A method for manufacturing a cage part 10 according to a first embodiment is shown (see figure 2 ) has been cut out of the planar plate strip 16. The planar metal strip 16 includes a first leg 20 , a web 18 and a second leg 22 . A transition region 32 to the two arms 20 , 22 is shown on both sides of the web 18 . The longitudinal axis 30 of the planar sheet metal strip 16 is shown in dotted lines. The surface normal is drawn against the sheet plane 23 . The second arm 22 ends in a circular portion 26 , which protrudes beyond the web 18 or the arm 22 by a corresponding width. Furthermore, the lug 18 also has a plurality of crimp-protruding contours 24 with an approximately angular cross-section. The contours 24 are introduced in a continuously alternating manner. Along the longitudinal axis 30 of the web 18 , the contours extend out of the plane of the drawing toward the viewer and inwards of the viewer away from the plane of the drawing in alternating fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com