Vacuum defoaming method for surface of workpiece

A vacuum defoaming technology on the surface of a workpiece, which is applied to the device and coating of the surface coating liquid, can solve the problems of difficult air bubbles, thick potting thickness, and large surface tension, so as to improve the surface quality of the product, Guarantee the sealing effect and improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

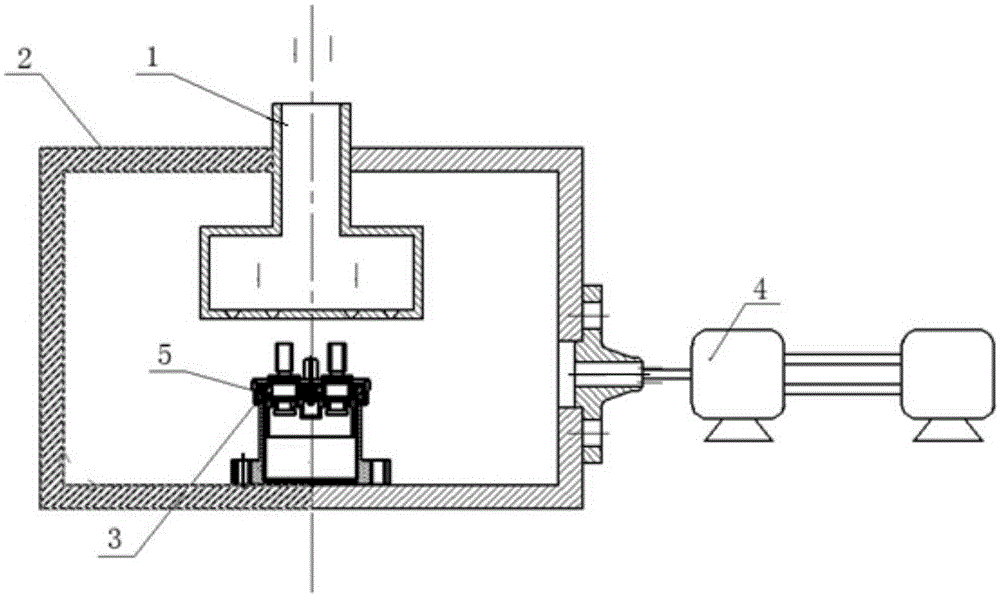

[0022] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

[0023] refer to figure 1 , the workpiece surface vacuum defoaming method, the specific steps are:

[0024] (1) The workpiece 3 is placed in the vacuum chamber 2, and the vacuum chamber 2 is connected with the vacuum pump 4 and the high-pressure air injection nozzle 1;

[0025] (2) Turn on the vacuum pump 4 to vacuumize, and after the vacuum pump 4 reaches the set time, close the vacuum pump 4;

[0026] (3) Open the high-pressure air injection nozzle 1, the high-pressure air quickly enters the vacuum chamber 2, and the bubbles on the surface of the workpiece 3 are broken due to the rapid change of the internal and external pressure difference, and at the same time, the pressure of the rapidly injected high-pressure gas acts on the surface of the bubbles so that the bubbles are blown;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com