Rotary shot blasting machine for concrete mixing drum

A technology of shot blasting machine and mixing drum, which is applied in the direction of abrasive jetting machine tools, used abrasive processing devices, abrasives, etc. It can solve problems such as turbulent flow, substandard quality, failure to clean or strengthen the surface, etc., to achieve Prevent dust turbulence, good cleaning effect and increase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

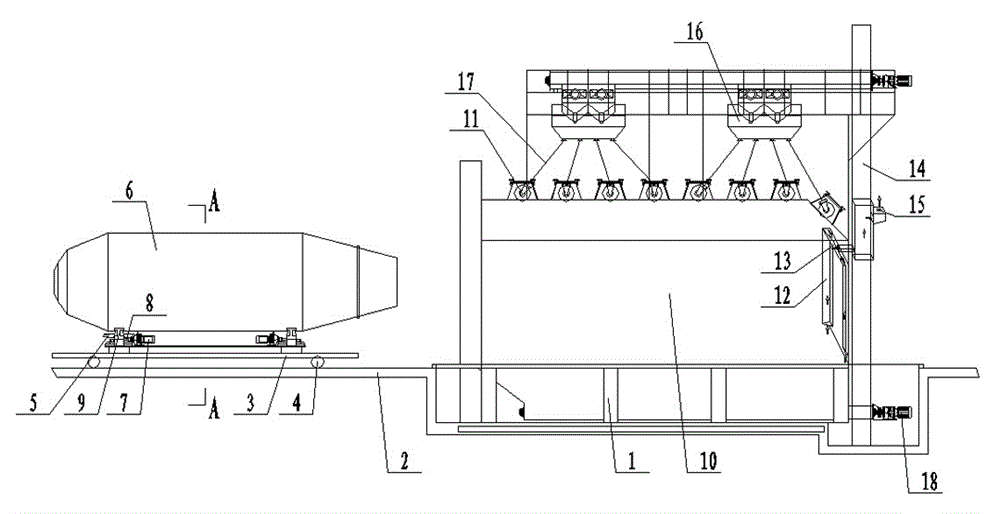

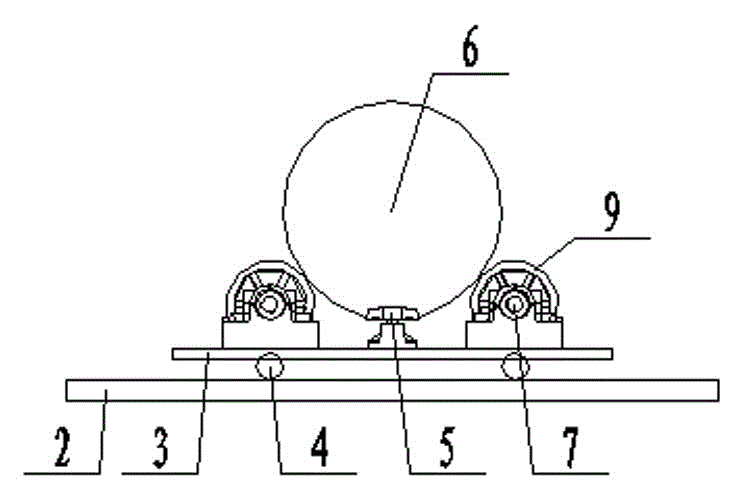

[0009] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0010] Such as figure 1 , figure 2 As shown, the concrete mixing drum rotary shot blasting machine includes: a frame 1, the frame 1 is supported on the ground 2, and a transport trolley 3 is arranged on one side of the frame 1, and the transport trolley 3 The lower end of the concrete mixing drum 6 is provided with a pulley 4, and support rollers 5 are respectively provided on both sides of the upper end of the conveying trolley 3. 3 are respectively provided with a high-frequency speed-regulating motor drive device 7, on the motor shaft 8 of the high-frequency speed-regulating motor drive device 7 is provided with a support wheel 9 that cooperates with the concrete mixing drum 6, and on the frame 1 There is a cleaning room 10, inside the upper end of the cleaning room 10, a number of shot blasting devices 11 are ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com