Frame for distributing rubber hoses to assembly stations

A technology for station distribution racks and hoses, which is applied to manufacturing tools, tool storage devices, workshop equipment, etc., can solve the problems of inconvenient access, affecting assembly quality and assembly efficiency, and achieves simple structure, cost saving, and high efficiency. The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

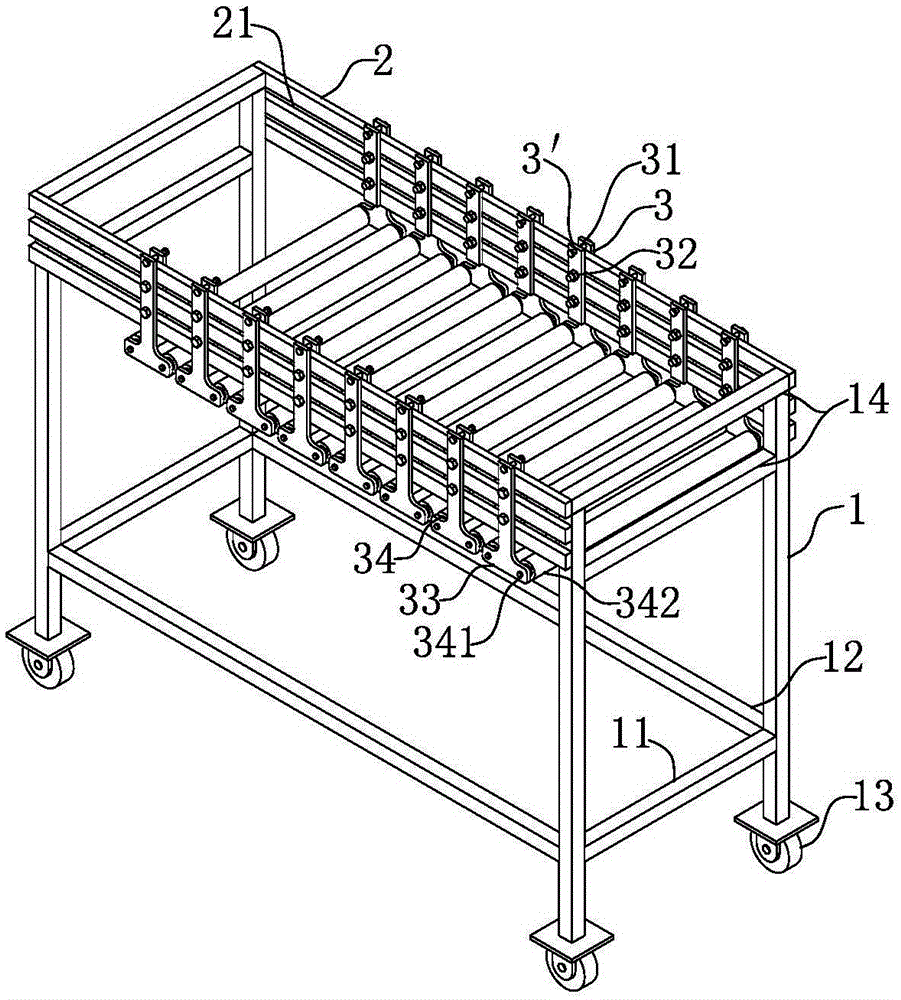

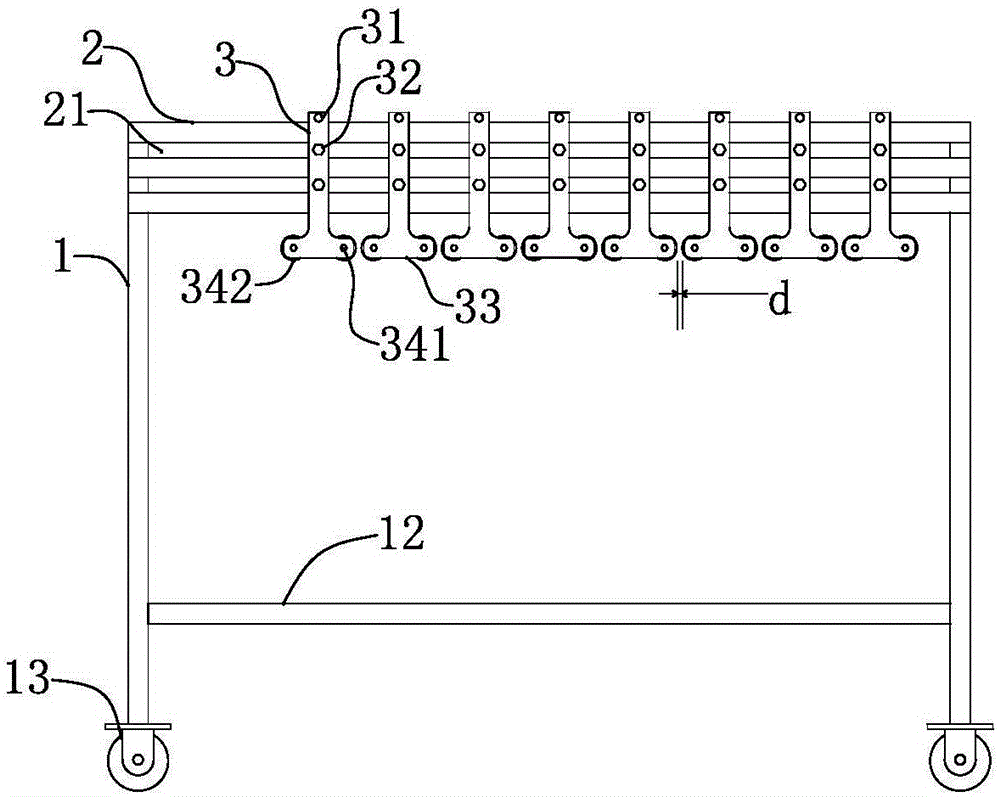

[0029] Such as Figure 2 to Figure 5 As shown, the present invention provides a rubber hose assembly station distribution frame, which is characterized in that it includes a support frame, a steel plate 2 and a fixing device, and there are multiple fixing devices that can slide on the steel plate 2 with each other And can be locked and fixed.

[0030] Such as figure 2 As shown, the support frame includes four vertically arranged legs 1, a running wheel 13 is provided under the legs 1, and the lower sides of the legs 1 on the left and right sides are connected with the first cross brace 11, and the left and right The upper sides of the legs 1 on both sides are connected by a third cross brace 14 , and the lower sides of the legs 1 on the front and rear sides are connected by a second cross brace 12 .

[0031] In a specific embodiment, in order to facilitate welding and manufacturing, the legs 1 and each cross brace are preferably square tubes; in addition, since the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com