Replaceable automatic centering facade lineation device of numerical control machine tool

A technology of CNC machine tools and scribing devices, applied to workshop equipment, manufacturing tools, etc., can solve problems such as poor performance and inability to replace scribing needles, and achieve the effects of improving work efficiency, good scribing effect, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The installation and working methods of the present invention will be described below in conjunction with the accompanying drawings.

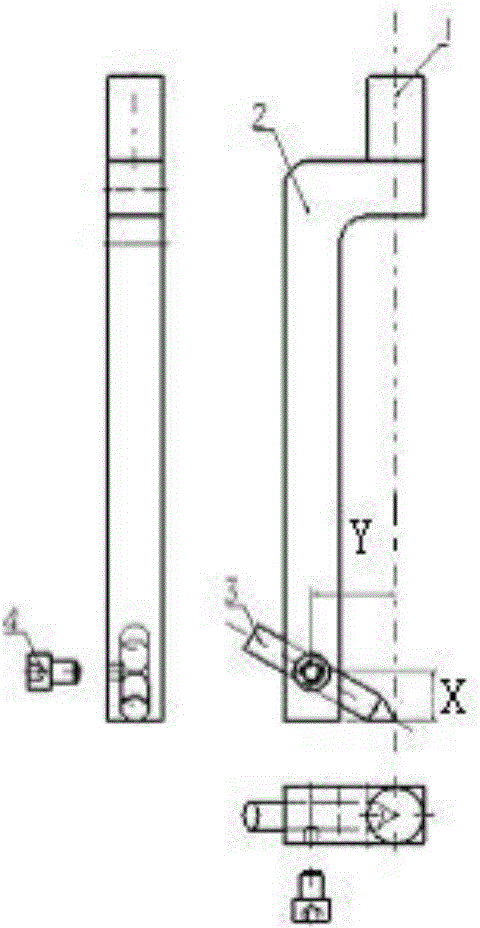

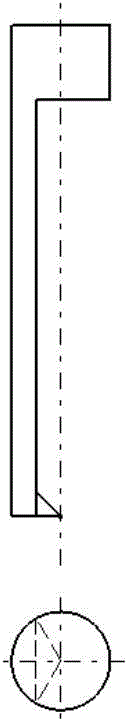

[0011] Such as figure 1 As shown, the connection part and the main part are integrally formed to ensure that the distance Y between the positioning clamping hole and the spindle axis is 30mm, the distance X between the positioning clamping hole and the main part is 17.32mm, and the through hole 5 forms an angle of 30° with the horizontal plane. The scribe needle 3 is made into an equilateral triangle whose tip cross section is 60°. Depend on figure 1 It can be seen that X / Y=tan30° is satisfied. At this time, the needle tip of the stylus coincides with the axis of the spindle, thereby realizing the tool setting of the replaceable automatic centering facade scribing device in the numerical control machining process. Before use, first place the end face of the main body 2 at an X distance from the positioning and clamping hole 6 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com