Short closed-loop control high-speed roller bed conveying mechanism

A conveying mechanism and high-speed roller technology, which is applied in the direction of roller table, transportation and packaging, etc., can solve the problems that affect production logistics budget, layout and planning design, low proportion of effective working time, high cost, etc., and achieve compact structure and save PLC The effect of fast resources and delivery speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

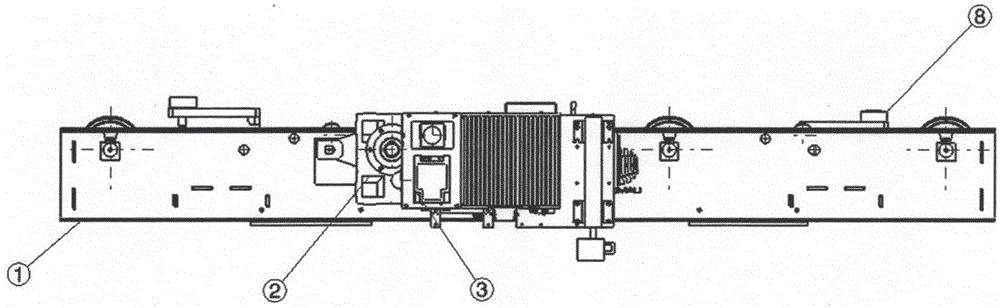

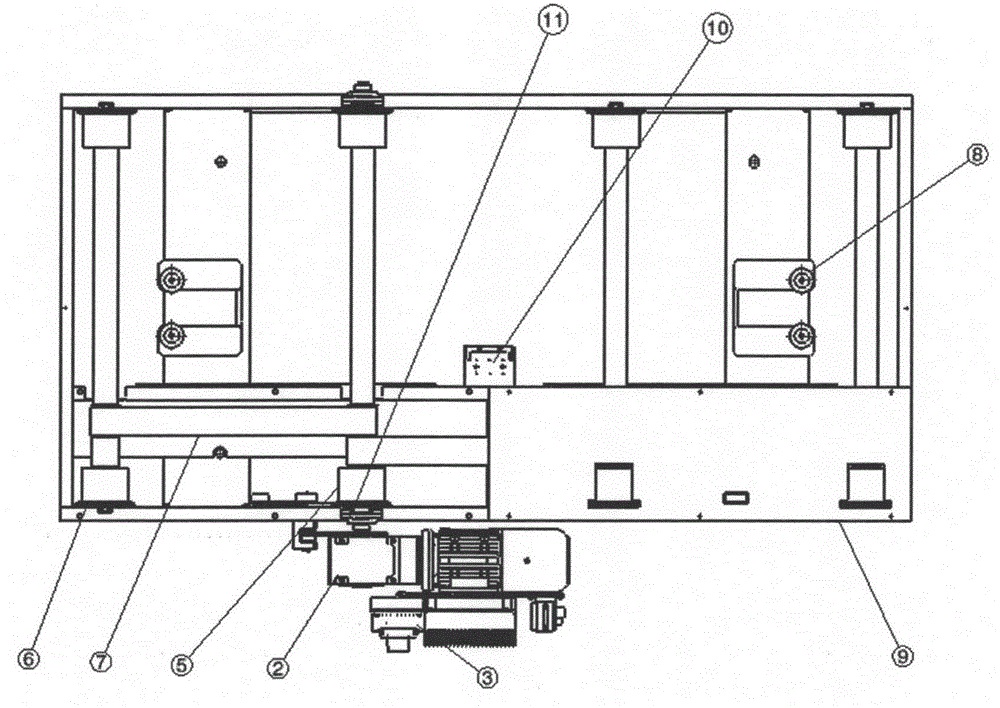

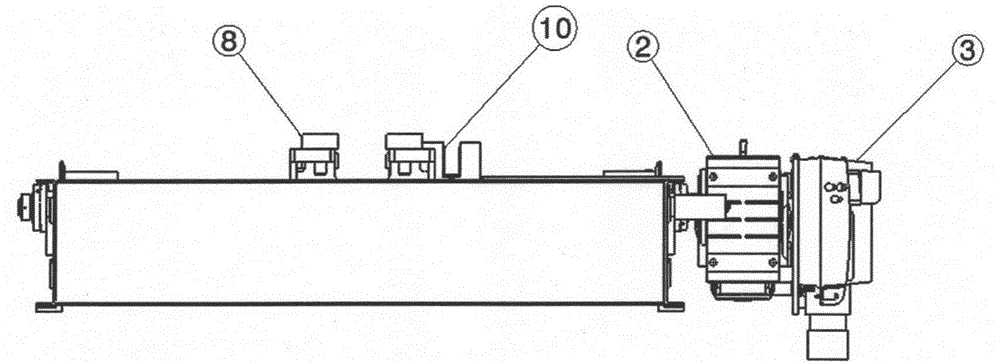

[0024] Such as Figure 1-3 As shown, a short closed-loop controlled high-speed roller bed conveying mechanism is provided for the present invention, which includes a roller bed 1 with a VersaDrive closed-loop control drive system. The VersaDrive closed-loop control drive system includes a drive motor 2 and a frequency converter 3. , Code reading decoder 10 and code ruler 13. The bed of the high-speed roller bed is 2.5m, and the production line is conventionally arranged at a station spacing of 2.9-3.2m. The bed 1 of the roller bed is equipped with a driving roller 5, three driven rollers 6, and a timing belt 7, forwarding The direction guide wheel assembly 8, the cover plate 9, and the driving roller 5 are fixed on the bed 1 through the flange bearing 11. The driving roller 5 and the driven roller 6 are provided with timing belt wheels, which are connected in pairs by a timing belt 7. The driving roller 5 is installed on the bed 1 of the high-speed roller bed conveying mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com