Tension-free compounding and slitting machine for elastic fabric

A tension-free, slitting machine technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of high production cost, unwinding and winding wrinkles, cumbersome operation, etc., and achieve disassembly, assembly, maintenance and replacement Convenience, ingenious overall structure design, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

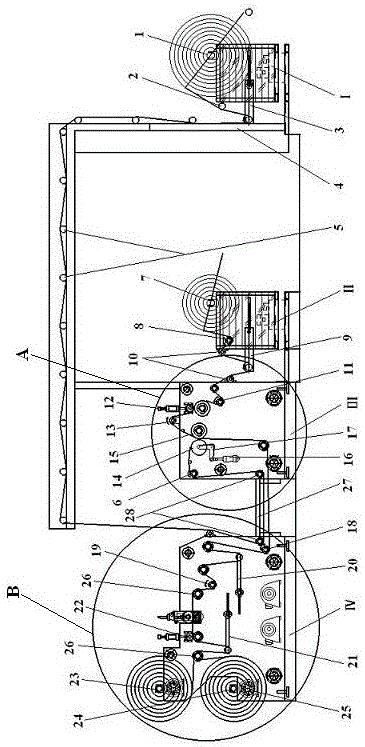

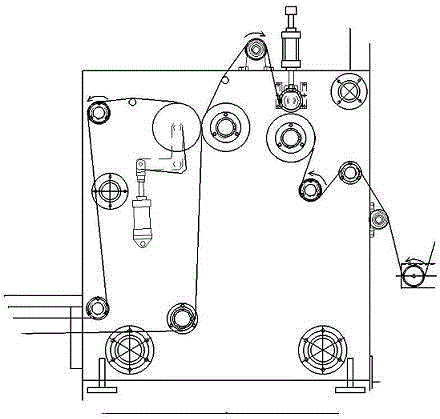

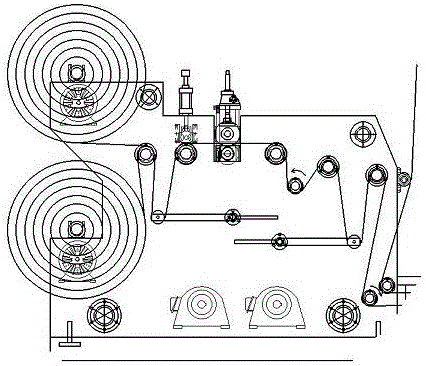

[0017] Such as figure 1 — image 3 , a tension-free composite slitting machine for elastic cloth, comprising a first unwinding mechanism I, a second unwinding mechanism II, a composite mechanism III and a slitting and winding mechanism IV, the first unwinding mechanism I, the second unwinding mechanism The rolling mechanism II is connected with the composite mechanism III, and the composite mechanism III is connected with the cutting and winding mechanism IV. The whole machine adopts PLC control system for automatic control, LCD touch screen interface operation, you can set the cutting width and quantity by yourself, and has a manual / automatic conversion function, which dynamically displays the working status of the whole machine, and the operation is simple and convenient. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com