Novel nanometer enhanced anti-sticking semiconductive non-woven fabric and processing technology thereof

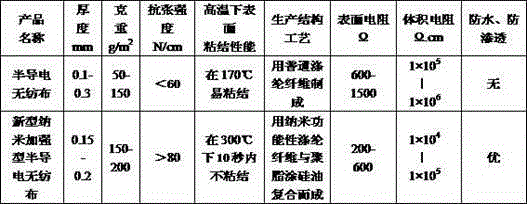

A processing technology and semi-conductive technology, which is applied in the field of new nano-reinforced anti-adhesive semi-conductive non-woven fabric and its processing technology, can solve the problems of non-waterproof, surface bonding, melting, and small pulling force, so as to reduce production costs, Excellent electrical conductivity and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

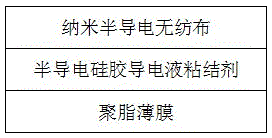

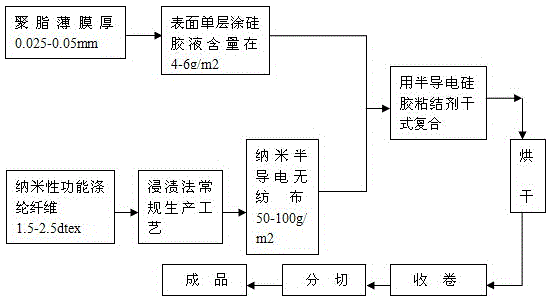

[0023] The present invention carries out according to the following steps:

[0024] 1) First, weave nano-functional polyester fibers into nano-semiconductive non-woven fabrics, and the weight of the nano-semiconductive non-woven fabrics is;

[0025] 2) Coat the upper surface of the polyester film with anti-adhesive semi-conductive silica gel;

[0026] 3) Then, the nano-semiconductive non-woven fabric is compounded with a semi-conductive silicone adhesive and a polyester film by a compound machine, and then cut.

[0027] The thickness of the nano-functional polyester fiber is 2dtex, and the weight of the nano-semiconductive non-woven fabric is 80 g / m 2 .

[0028] The thickness of the polyester film is 0.04mm.

[0029] The amount of anti-adhesive semi-conductive silicone in the step 2) is 5g / m 2 .

[0030] In the step 3), the coating amount of the semi-conductive silicone adhesive is 8g / m 2 .

[0031] The composition ratio of the anti-adhesive semi-conductive silica gel i...

Embodiment 2

[0034] The present invention carries out according to the following steps:

[0035] 1) First, weave nano-functional polyester fibers into nano-semiconductive non-woven fabrics, and the weight of the nano-semiconductive non-woven fabrics is;

[0036] 2) Coat the upper surface of the polyester film with anti-adhesive semi-conductive silica gel;

[0037] 3) Then, the nano-semiconductive non-woven fabric is compounded with a semi-conductive silicone adhesive and a polyester film by a compound machine, and then cut.

[0038] The thickness of the nano-functional polyester fiber is 1.5dtex, and the weight of the nano-semiconductive non-woven fabric is 50 g / m 2 .

[0039] The thickness of the polyester film is 0.025mm.

[0040] The amount of anti-adhesive semi-conductive silicone in the step 2) is 4 g / m 2 .

[0041] In the step 3), the coating amount of the semi-conductive silicone adhesive is 10g / m 2 .

[0042] The composition ratio of the anti-adhesive semi-conductive silica ...

Embodiment 3

[0045] Follow the steps below:

[0046] 1) First, weave nano-functional polyester fibers into nano-semiconductive non-woven fabrics, and the weight of the nano-semiconductive non-woven fabrics is;

[0047] 2) Coat the upper surface of the polyester film with anti-adhesive semi-conductive silica gel;

[0048] 3) Then the nano-semiconductive non-woven fabric is compounded with a semi-conductive silicone adhesive with a compound machine, and cut into pieces.

[0049] The thickness of the nano-functional polyester fiber is 2.5dtex, and the weight of the nano-semiconductive non-woven fabric is 100 g / m 2 .

[0050] The thickness of the polyester film is 0.05mm.

[0051] The amount of anti-adhesive semi-conductive silicone in the step 2) is 6 g / m 2 .

[0052] In the step 3), the coating amount of the semi-conductive silicone adhesive is 8g / m 2 .

[0053] The composition ratio of the anti-adhesive semi-conductive silica gel is: 33% of silica gel, 55% of ethyl ester, 12% of cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com