On-line Density Detection Structure of Mixed Drilling Fluid

A detection structure and density detection technology, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc., can solve the problems of wasting drilling fluid materials, incorrectly sensing pressure, and failing to detect density, etc., and achieve saving The effect of density detection time, guaranteed sealing performance, and limited space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

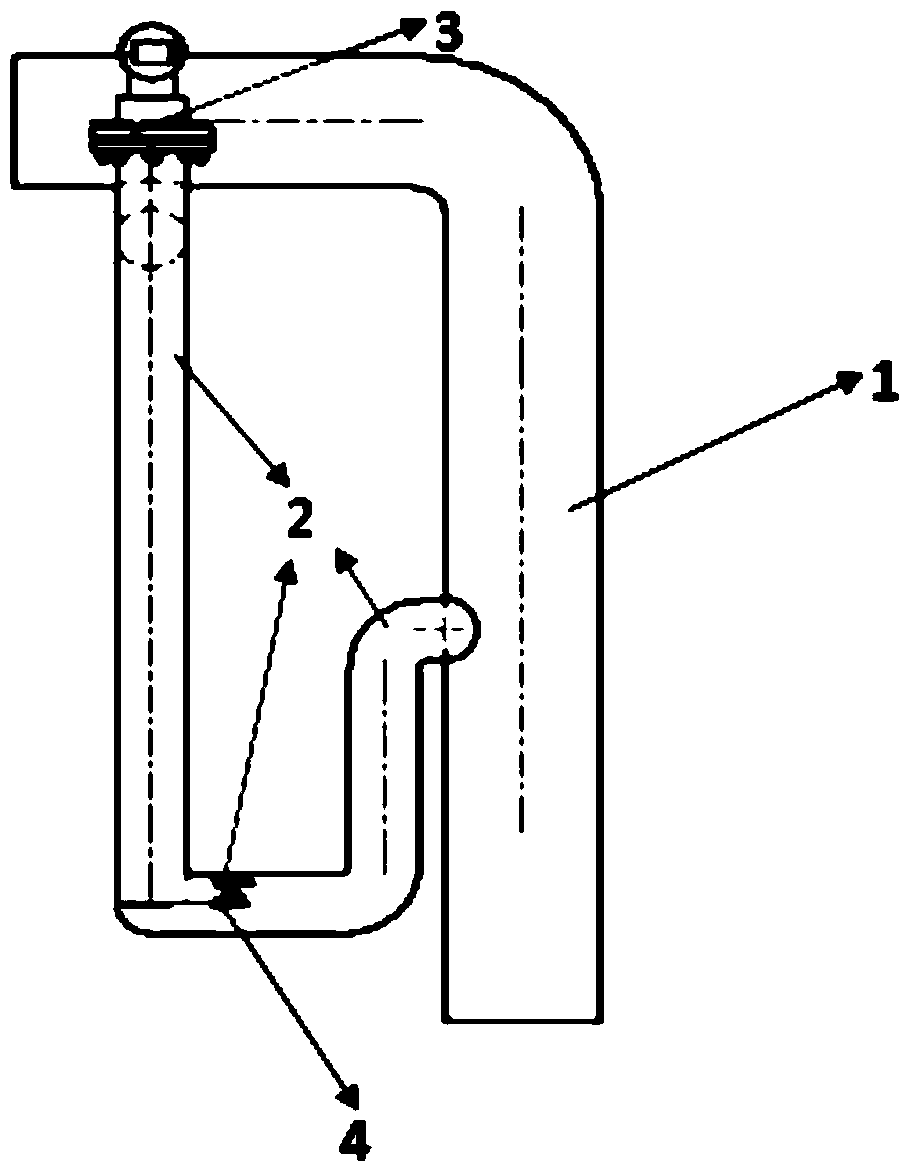

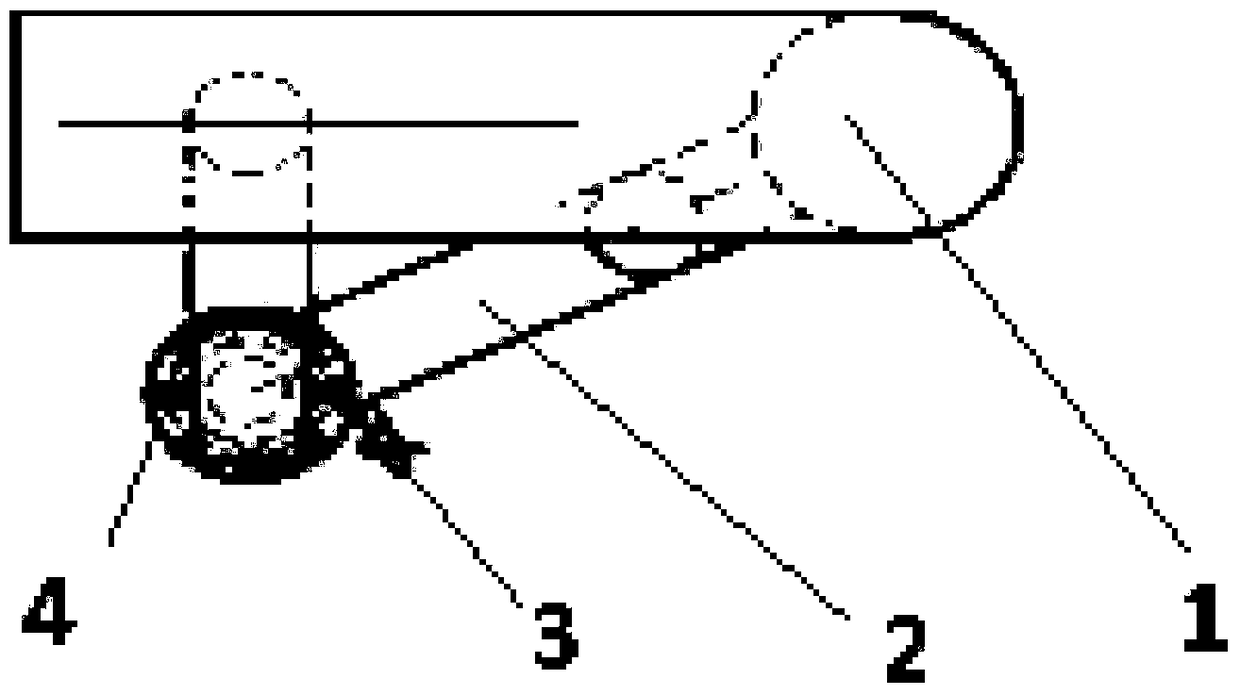

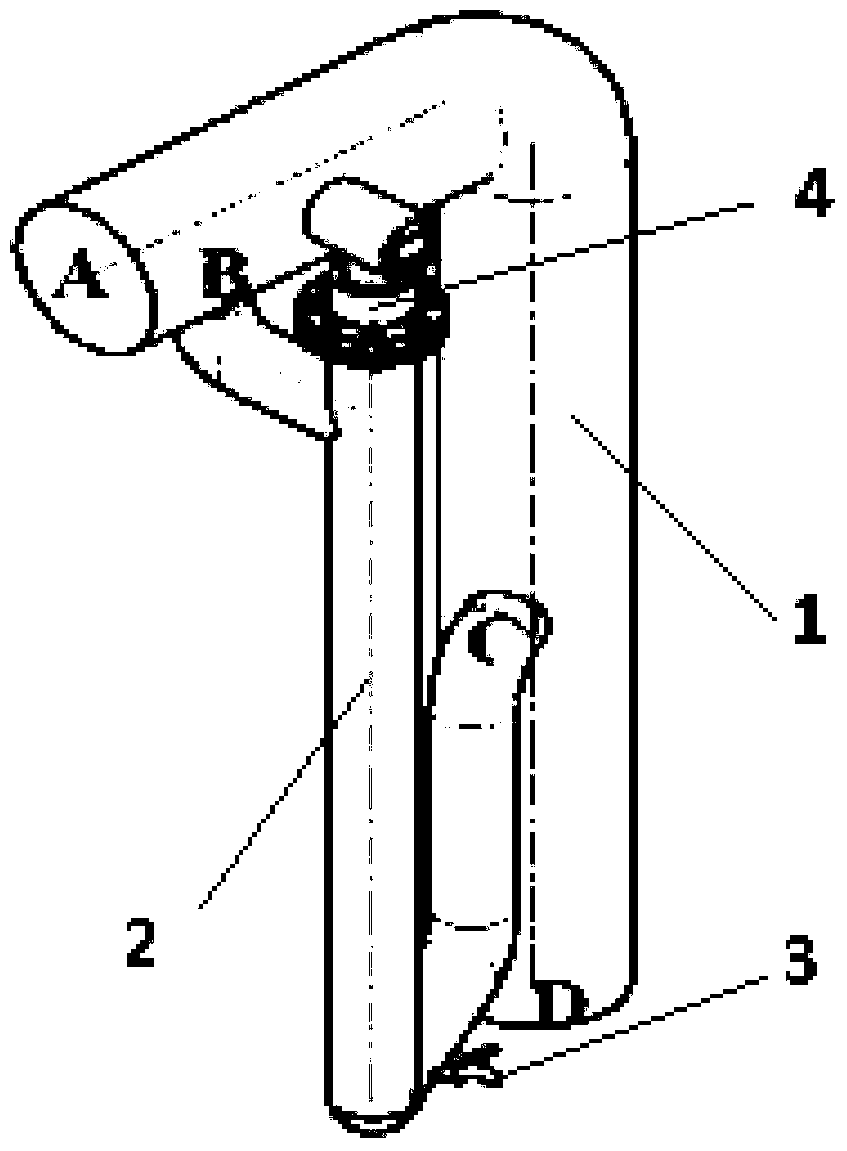

[0026] see Figure 1a to Figure 1c , is a preferred embodiment of the mixed drilling fluid online density detection structure, including an inverted L-shaped main pipeline 1 of the mixed drilling fluid. The main pipeline 1 includes a horizontal main pipeline 1, a vertical main pipeline 1, and also includes A U-shaped density detection pipeline 2 and a differential pressure density meter 3, the density detection pipeline 2 includes a first vertical pipe, a second vertical pipe and a connecting pipe connected between the lower ends of the first vertical pipe and the second vertical pipe , the length of the first vertical pipe is greater than the length of the second vertical pipe, the upper end of the first vertical pipe communicates with the horizontal main pipe 1 through the connecting pipe, and the second vertical pipe communicates with the vertical main pipe 1 through the connecting pipe , forming a one-piece structure. The differential pressure density meter 3 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com