Ultrasonic non-invasive pressure detection method based on information fusion of multiple converted waveforms

A waveform information, non-intrusive technology, applied in the direction of fluid pressure measurement using acoustic methods, can solve the problems of container cracks, propagation delay changes, inconvenient addition of temporary monitoring points, etc., to avoid errors and high pressure measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

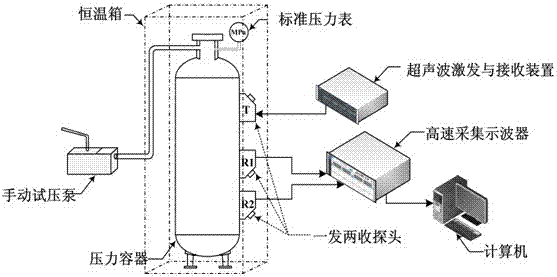

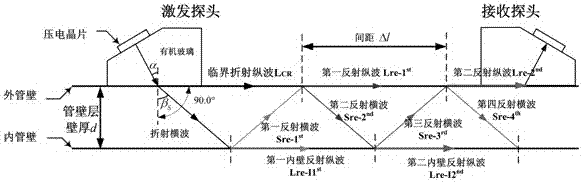

[0028] like figure 1 As shown, the ultrasonic waves are generated by the ultrasonic excitation device (CUT-2000A flaw detector), and then incident on the outer pipe wall of the pressure vessel at a critical angle, the path of its propagation in the pipe wall of the pressure vessel is as follows figure 2 shown. The specific propagation process is: when the incident longitudinal wave is incident at the first critical angle, the wave mode conversion occurs at the interface between the ultrasonic probe and the pressure vessel wall, and a critical refracted longitudinal wave L is generated at the outer wall CR and refracted transverse waves, critically refracted longitudinal waves L CR Propagate along the outer pipe wall to the receiving probe to be received; the refracted shear wave propagates in the pressure vessel pipe wall and is reflected at the inner pipe wall to generate the first inner wall reflected longitudinal wave L re-I1 st and the first reflected shear wave S re-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com