Oil filter bypass valve opening pressure gas detection device

A technology of oil filter and opening pressure, applied in the field of parts inspection, can solve the problems of high input cost and inspection cost, high cost, complicated structure, etc., and achieves low device input cost and inspection cost, improved sealing performance, and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] As shown in Figure 4, the oil filter bypass valve includes a valve body 101, an end cap 102 installed on the top of the valve body, a spring 103 arranged in the valve body, a gasket 104 arranged on the top of the spring 103, and the end cap of the valve body 102 is provided with an opening, and the sealing gasket 104 seals the opening under the elastic force of the spring 103;

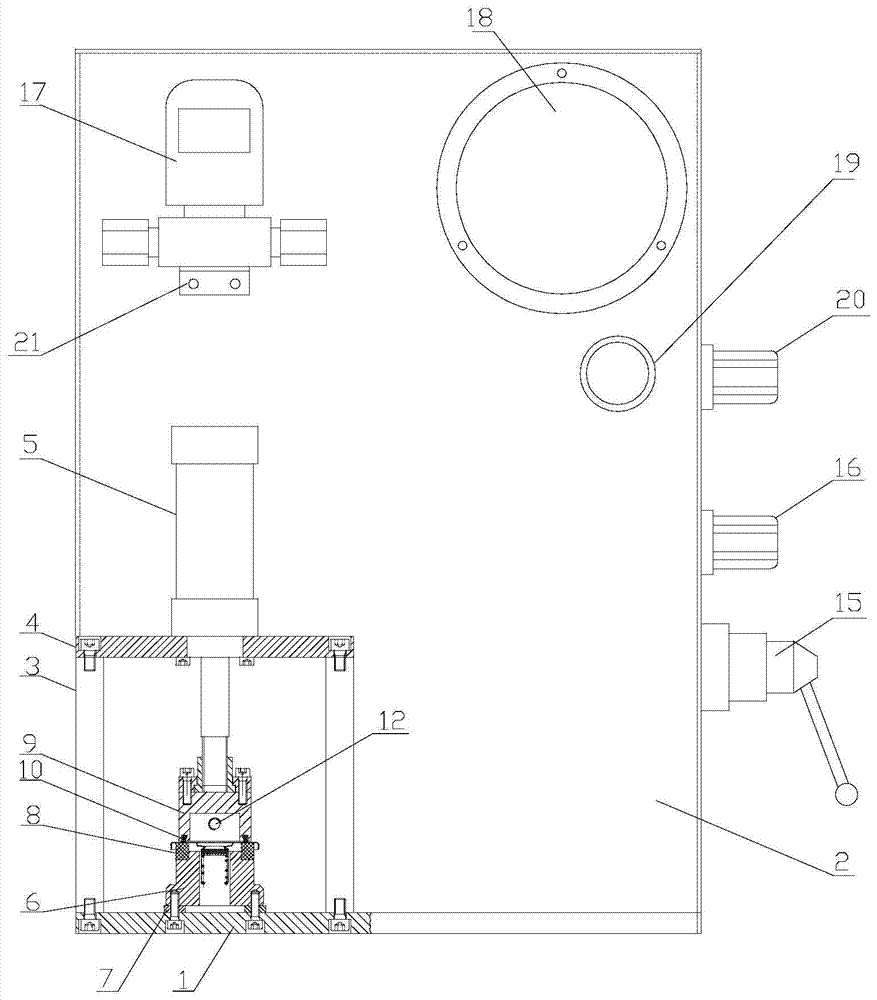

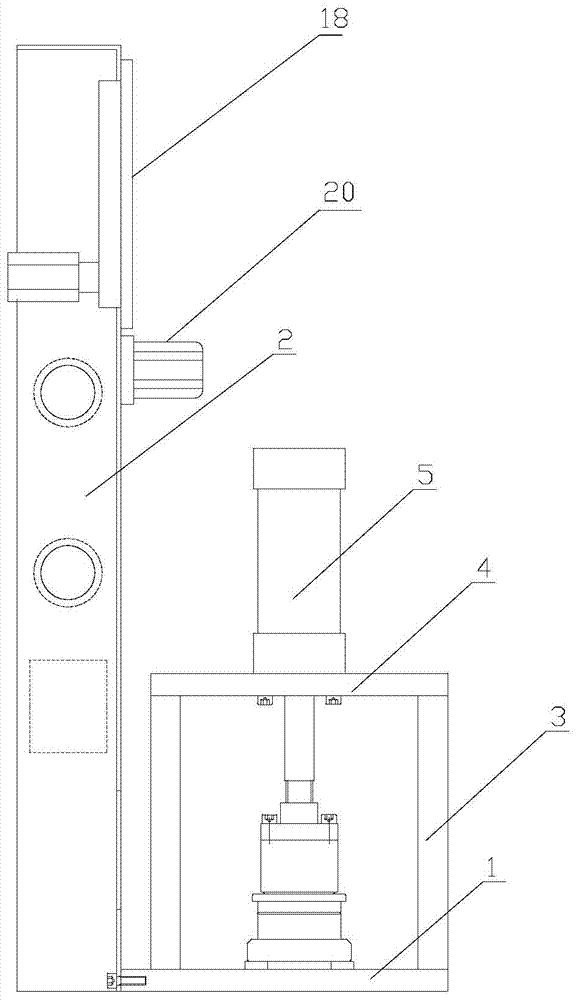

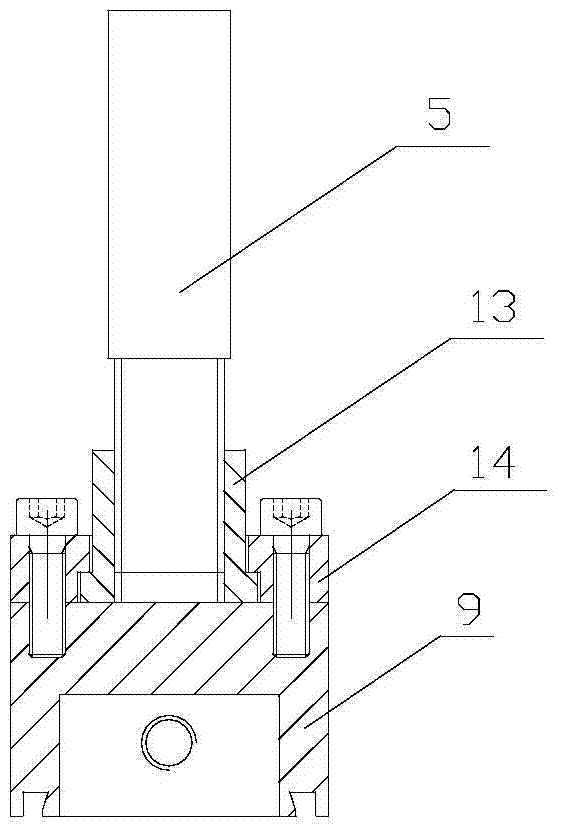

[0026] See Figure 1-Figure 4 , the oil filter bypass valve opening pressure gas detection device includes a base 1, a mounting plate 2 arranged on the side of the base 1, a support rod 3 fixedly connected to the base, and a cylinder fixing seat fixedly connected to the top of the support rod 3 4. The cylinder body of the cylinder 5 set on the cylinder fixing seat 4, the lower mold 6 fixedly installed on the base 1, the gasket 7 arranged between the lower mold 6 and the base 1, and the ring at the top of the lower mold The lower sealing ring 8 on the step surface, the inflatable disk 9 arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com