Ball placement detection equipment and application thereof

A testing equipment and ball-planting technology, which is applied in the direction of optical testing for flaws/defects, can solve the problems of misjudgment, time-consuming, and unfavorable implementation of light-sensing sensors, and achieves simple installation and adjustment, simple and accurate operation, and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

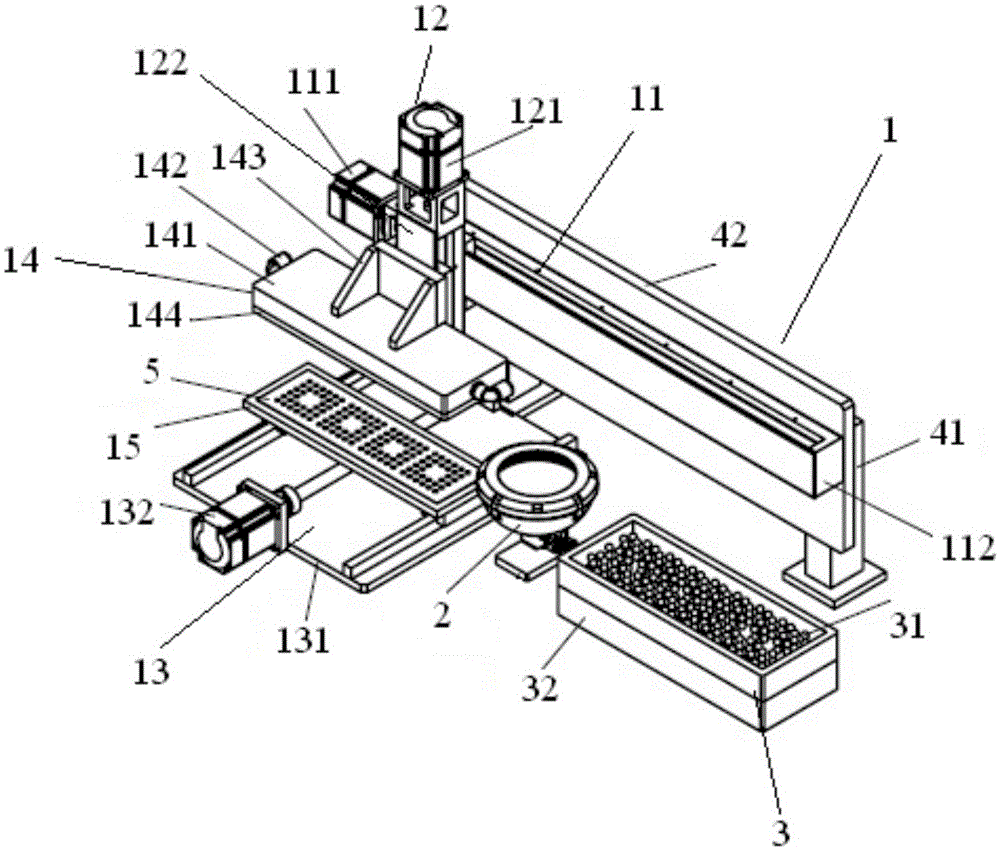

[0067] A kind of implant detection equipment, its structure is as follows: figure 1 As shown, the testing equipment is set on a platform, and the testing equipment includes a ball planting unit 1, a testing unit 2 and a ball supplying unit.

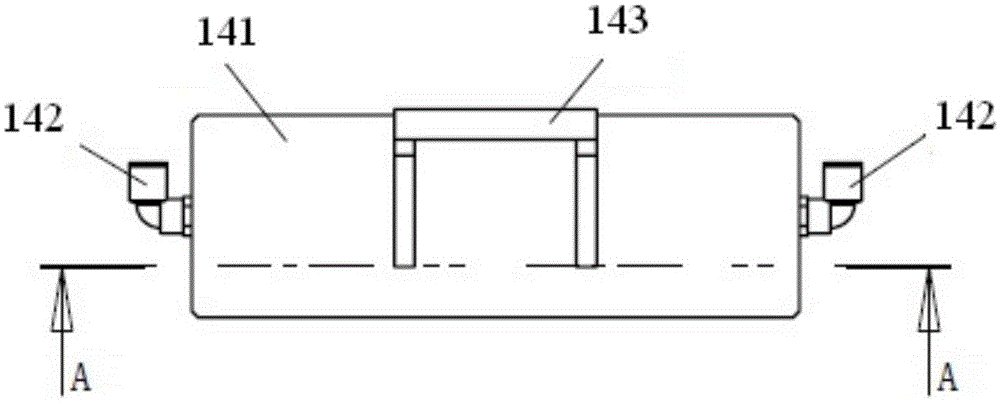

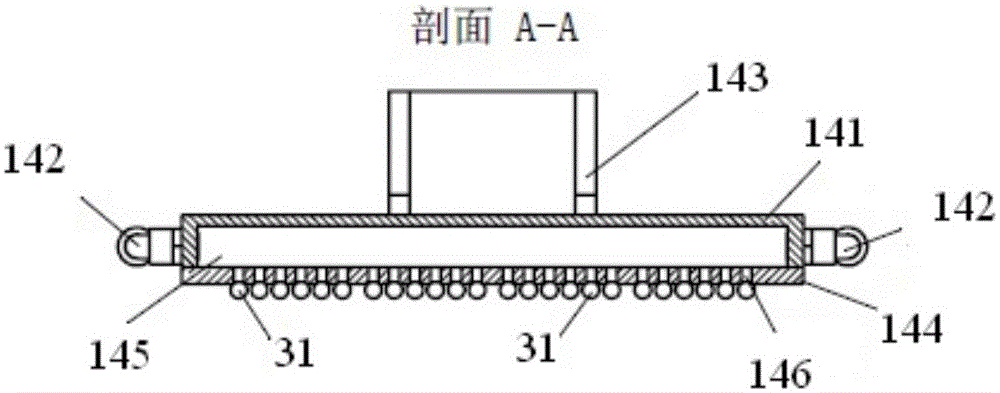

[0068] The ball planting unit 1 comprises a conveying device, and a ball planting device 14 and a substrate placing platform 15 arranged on the conveying device, the substrate placing platform 15 is provided with a substrate 5, and the conveying device is formed along the directions of the X axis, the Y axis and the Z axis respectively. The moving X-direction conveying device 11, the Y-direction conveying device 12 and the Z-direction conveying device 13 are composed;

[0069] The X-direction transmission device 11 is arranged on the supporting device 4 fixed on the stand, and the X-direction transmission device 11 includes an X-direction controller 111 and an X-direction transmission plate 112 arranged on the support device, and the X-di...

Embodiment 2

[0080] The application of the ball planting detection equipment as described in embodiment 1 may further comprise the steps:

[0081] (a) Solder ball pickup

[0082] Adjust the X-direction controller 111 to control the Y-direction transfer device 12 equipped with the ball planting device 14 to move to the top of the ball supply unit 3 along the X-axis direction, and then adjust the Y-direction controller 121 to control the ball planting device 14 to descend along the Y-axis direction To pick up the height of the solder ball, turn on the vacuum generator, absorb the solder ball 31 from the ball supply unit 3, and then adjust the Y direction controller 121 to control the ball planting device 14 to rise to the initial height along the Y axis;

[0083] (b) Solder ball pickup defect detection

[0084] Adjust the X-direction controller 111 to control the ball planting device 14 that has absorbed the solder ball 31 to move to the top of the detection unit 2 along the X-axis directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com