Self-heating experimental simulation device for combustible solids

An experimental simulation, flammable solid technology, applied in the direction of material thermal development, can solve the problem of difficult to reflect the self-heating process of flammable substances, and achieve good heat storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with specific examples.

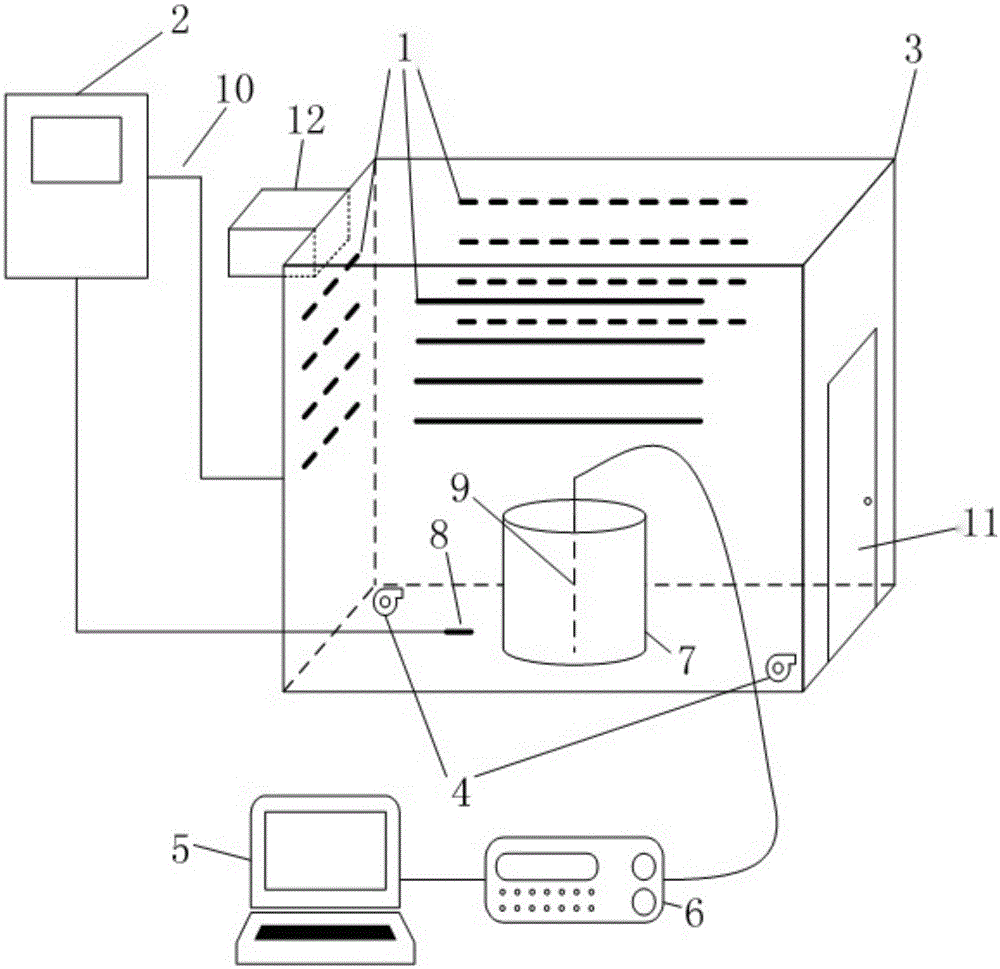

[0018] Such as figure 1 As shown, the flammable solid self-heating experimental simulation device described in this embodiment includes a combustion chamber 3, an infrared heating tube 1, a centrifugal blower 4, an exhaust fan 12, a stainless steel insulation barrel without a cover 7, and a constant temperature heating control Box 2, armored thermocouple 9, data acquisition instrument 6. Wherein, the combustion room 3 is a rectangular room with four walls in total. A fire door 11 is provided on one of the walls, and infrared heating tubes 1 are installed on the inner walls of the remaining three walls. The centrifugal blower 4 is placed to promote the air flow in the combustion room, so that the temperature inside the combustion room is uniform. An exhaust fan 12 is installed on the upper part of the combustion room 3 to prevent the self-heating of solid flammable substances ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com