Method for predicting size of low-speed impact dent of circular metal sheet

A metal sheet, low-velocity impact technology, applied in the direction of testing the strength of materials with one-time impact force, special data processing applications, instruments, etc., can solve the problems of high test cost, complicated analysis method, inconvenient theoretical solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

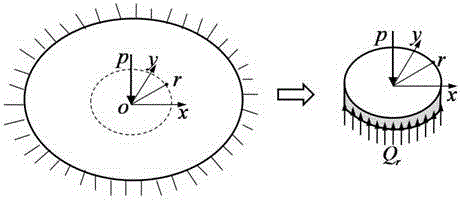

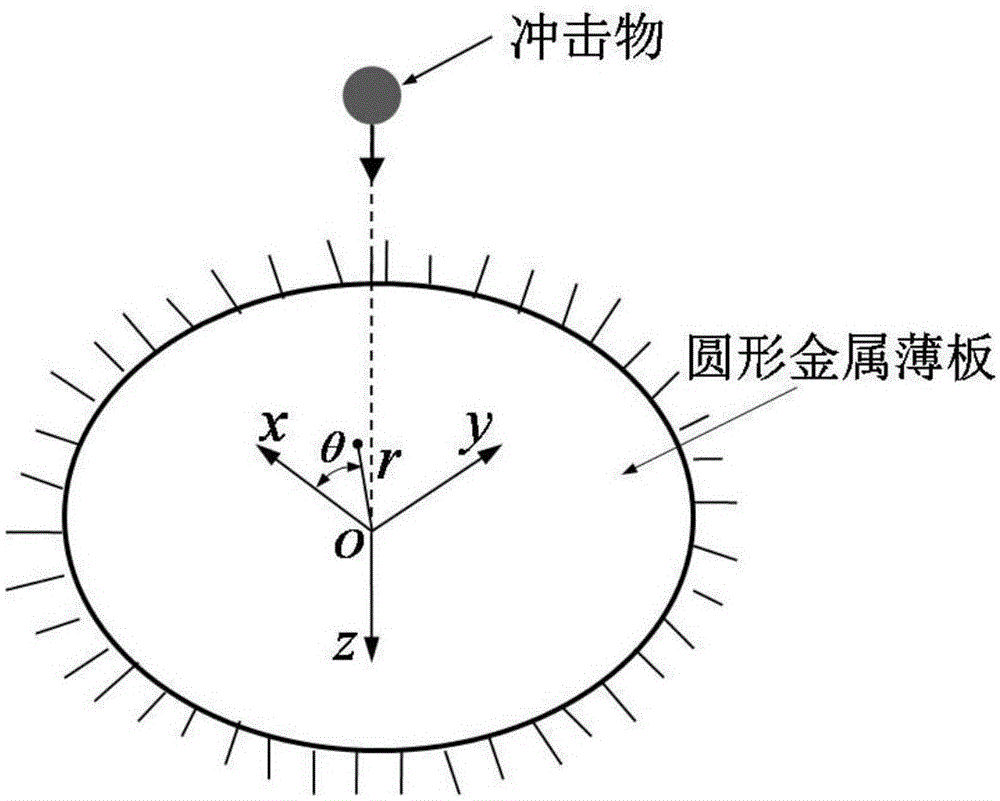

[0095] Figure 4 It is a flow chart of the method of the present invention. The present invention is implemented in 4 steps, specifically:

[0096] Step 1. Propose the assumptions of a new method for predicting the size of circular metal sheet low-velocity impact pits.

[0097] Assumptions include:

[0098] (1) The shape of the impact pit of the thin metal plate is rotationally symmetric, and the influence of springback deformation on the size of the pit is not considered;

[0099] (2) The Kirchhoff-Love thin plate hypothesis is satisfied, so the influence of out-of-plane normal stress and transverse shear stress can be ignored, mainly radial tensile stress, radial bending stress and circumferential bending stress;

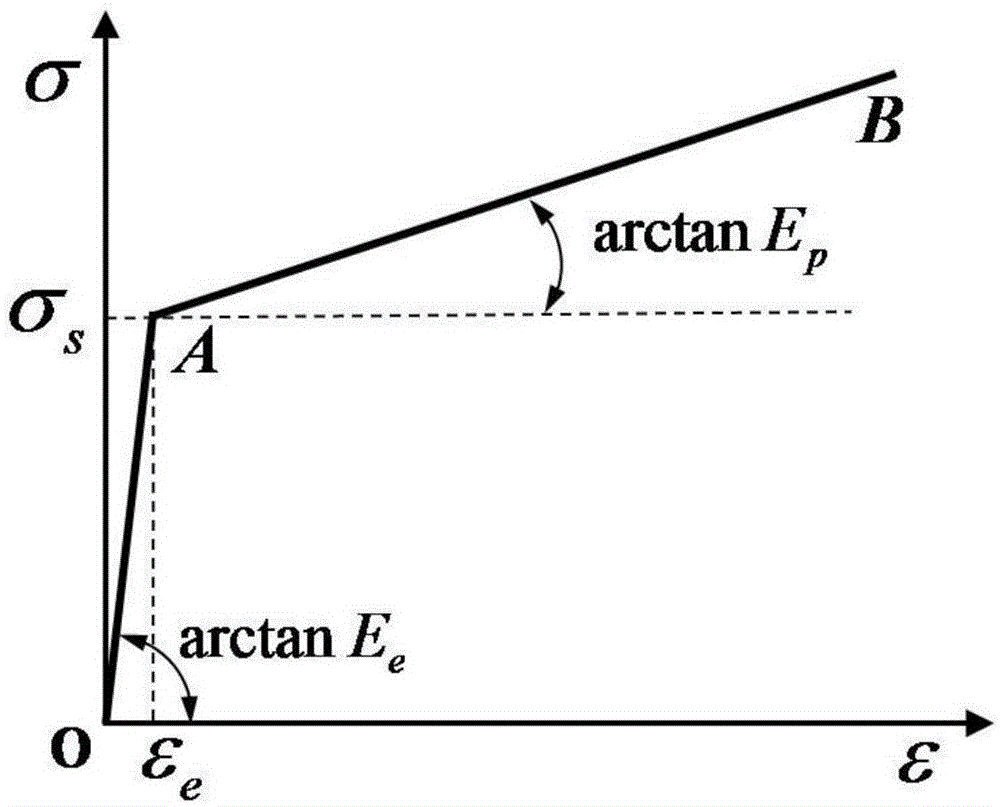

[0100] (3) The material of the metal sheet is an elastic-plastic linear strengthening material, and its stress-strain relationship is as image 3 As shown, the line segment OA is the elastic phase, and the line segment AB is the plastic phase, and the corresponding slopes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com