Method for preparing cigar tobacco leaves by virtue of oxidase fermentation

A cigar tobacco leaf and oxidase technology, which is applied in the directions of tobacco, application and treatment of tobacco, can solve the problems of less research and application of tobacco leaves, and achieve the effects of improved flammability, improved gray score, and improved bitterness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

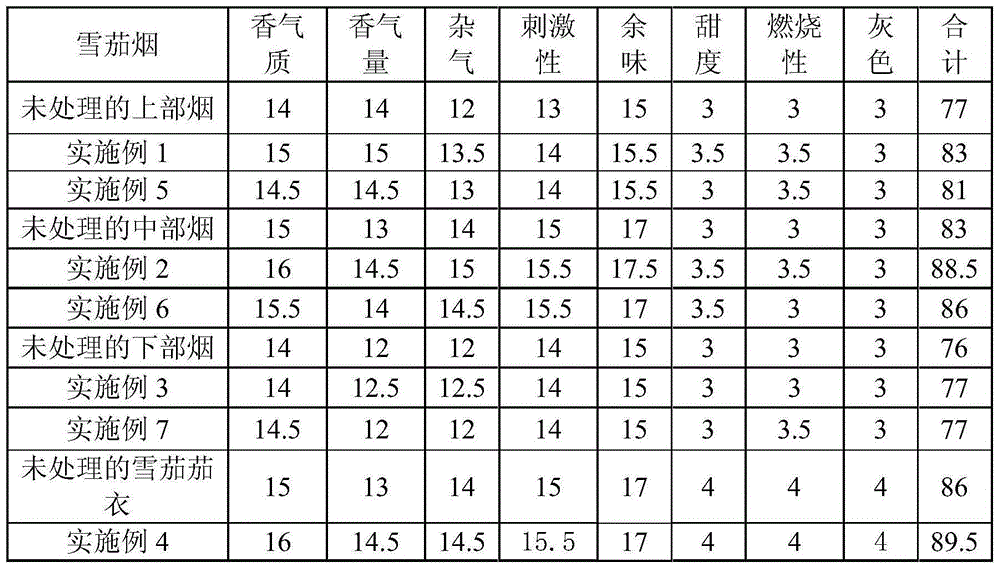

Examples

Embodiment 1

[0029] The method for preparing cigar tobacco leaves by mixed enzyme fermentation comprises the following steps:

[0030] 1) Alcoholize 30kg of the upper part of the cigar filler under natural conditions for one year, and then remoisturize the upper part under vacuum;

[0031] 2) dissolving the mixed enzyme in deionized water to obtain a mixed enzyme aqueous solution, wherein the polyphenol oxidase enzyme activity in the oxidase aqueous solution is 18 U / ml, and the peroxidase enzyme activity is 4.8 U / ml;

[0032] 3) Put the leaf petiole end of the tobacco leaves treated with moisture regain in step 1) in the mixed enzyme aqueous solution to soak the handle for 30 minutes, and then spray the mixed enzyme aqueous solution on the tobacco leaves according to the weight ratio of 1:10 to obtain the tobacco leaves containing the mixed enzyme, wherein, per gram In the tobacco leaves containing mixed enzymes, the enzyme activity of polyphenol oxidase is 1.8U / ml, and the activity of per...

Embodiment 2

[0036] The method for preparing cigar tobacco leaves by peroxidase fermentation comprises the following steps:

[0037] 1) Aging 30kg of the middle part of the cigar filler under natural conditions for one year, and then re-moisture the upper part of the smoke under vacuum conditions;

[0038] 2) dissolving the peroxidase in deionized water to obtain a peroxidase aqueous solution, wherein the peroxidase enzyme activity in the peroxidase aqueous solution is 6 U / ml;

[0039] 3) Place the tobacco leaf petiole end of step 1) remoisturized in the peroxidase aqueous solution to soak the handle for 20 minutes, then spray the peroxidase aqueous solution on the tobacco leaves in a weight ratio of 1:10 to obtain peroxidase-containing Tobacco leaves, wherein, per gram of tobacco leaves containing peroxidase, the peroxidase enzyme activity is 0.6U; let stand for 24 hours to balance the water in the tobacco leaves, and then adjust the moisture content of the tobacco leaves to 24%;

[0040...

Embodiment 3

[0043] The method for preparing cigar tobacco leaves by polyphenol oxidase fermentation comprises the following steps:

[0044] 1) Aging 30kg of the lower part of the cigar filler under natural conditions for one year, and then re-moisture the upper part of the smoke under vacuum conditions;

[0045] 2) dissolving polyphenol oxidase in deionized water to obtain an aqueous solution of polyphenol oxidase, wherein the activity of polyphenol oxidase in the aqueous solution of polyphenol oxidase is 15 U / ml;

[0046] 3) Put the petiole end of the tobacco leaves treated in step 1) in the polyphenol oxidase aqueous solution to soak the stalk for 10 minutes, and then spray the polyphenol oxidase aqueous solution on the tobacco leaves according to the weight ratio of 1:10 to obtain polyphenol oxidase containing polyphenol oxidase. Tobacco leaves, wherein, per gram of tobacco leaves containing polyphenol oxidase, the enzyme activity of polyphenol oxidase is 1.5U; standing for 24 hours to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com