Oil-purification environmental protection equipment

A kind of environmental protection equipment and oil purification technology, which is applied in the direction of fat oil/fat refining, filtration circuit, filtration separation, etc., can solve problems such as trouble and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

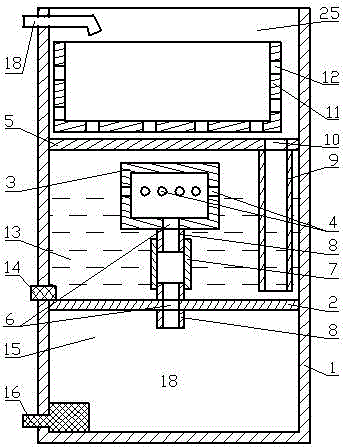

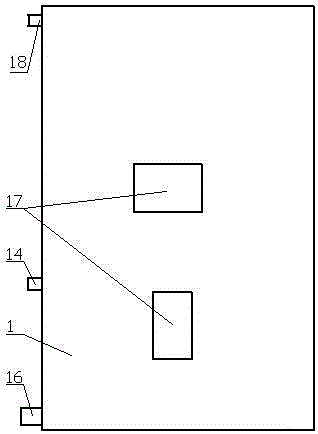

[0059] The clean oil environmental protection equipment of the present invention mainly includes a box body 1, a filter residue box, an upper partition 5, a sealing plate 2, a clean oil float 3, an oil suction hole 4, a swallowing hole 6, an oil suction pipe 8, a telescopic pipe 7, an oil inlet pipe 18, a net Oil chamber 13, oil storage chamber 15, filter chamber 25, observation window 17, oil pump 16.

[0060] An upper partition 5 and a sealing plate 2 are horizontally fixed in the casing 1 to divide the casing 1 into a filter chamber 25, a clean oil chamber 13 and an oil storage chamber 15. The upper part of the filter chamber 25 in the casing 1 is clean. The middle part of the oil chamber 13 in the casing 1 between the filter chamber 25 and the oil storage chamber 15, the lower part of the oil storage chamber 15 in the casing 1; the upper side of the upper partition 5 is the bottom of the filter chamber 25, The lower side is the top of the clean oil chamber 13, the upper si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com