Chemical parallel reaction device

A parallel reaction and chemical technology, applied in chemical/physical/physical-chemical fixed reactors, etc., can solve the problems of complex operation, difficult to achieve, and weak operation ability at the same time, and achieves simple operation, improved automation, and accelerated screening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

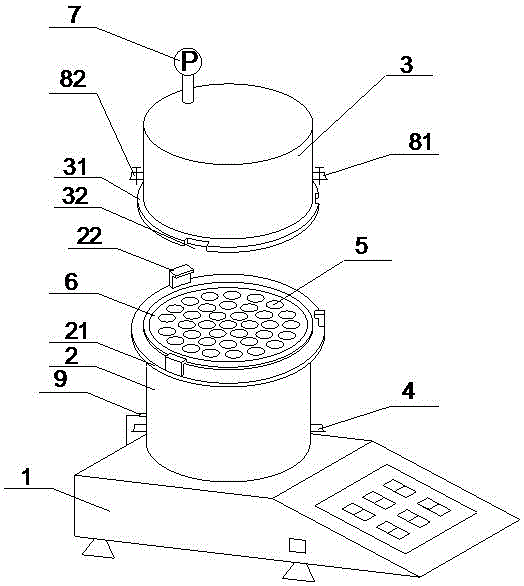

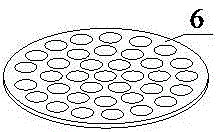

[0021] Such as figure 1 As shown, a chemical parallel reaction device includes a magnetic heating stirrer 1, a heating column 2, and a sealing cover 3. The heating column 2 is placed on the heating panel of the magnetic heating stirrer 1. The upper end of the heating column 2 is integrally formed with an upper The connecting plate 21 and the lower end of the sealing cover 3 are integrally formed with a lower connecting plate 31, and the upper connecting plate 21 and the lower connecting plate 31 are correspondingly provided with a matching positioning block 22 and a positioning groove 32, and the heating column 2 and the sealing cover 3 There is a metal sealing gasket (not shown in the figure) between them, and the heating column 2 and the sealing cover 3 are sealed and connected through the snap fit of the positioning block 22 and the positioning groove 32; wherein, the bottom of the heating column 2 is provided with a condensation The water pipe 4, the middle and lower part ...

Embodiment 2

[0026] A chemical parallel reaction device, the structure of which is basically the same as that of Embodiment 1, and the only difference from Embodiment 1 is that the top of the heating column 2 omits the setting of the reactor column holder 6 .

[0027] This kind of embodiment is applicable to the situation that the reactor is a reactor or similar to it, and the perspective view of the reactor is shown in Figure 4 , sectional view see Figure 5 , the reactor is composed of a kettle body and a kettle cover.

[0028] When a reaction is required, the sealing cover 3 is removed, the required samples and magnets are added to the reaction kettle, and the reaction kettles are placed in the reactor accommodation hole 5 one by one, and then the heating column 2 and the sealing cover 3 are passed through the sealing gasket Sheet, positioning block 22 and positioning groove 32 are sealed and connected. If a reaction with pressure is required, connect the gas cylinder with the requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com