Building waste crushing device

A crushing device and building technology, applied in the direction of grain processing, etc., can solve the problems of restricting the crushing operation of building waste, unrealistic cost of the crusher, and large size of the crusher, so as to achieve good crushing and refining effect and reduce labor work Quantity, the effect of improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and examples, wherein the schematic implementations and descriptions are only used to explain the present invention, but are not intended to limit the present invention.

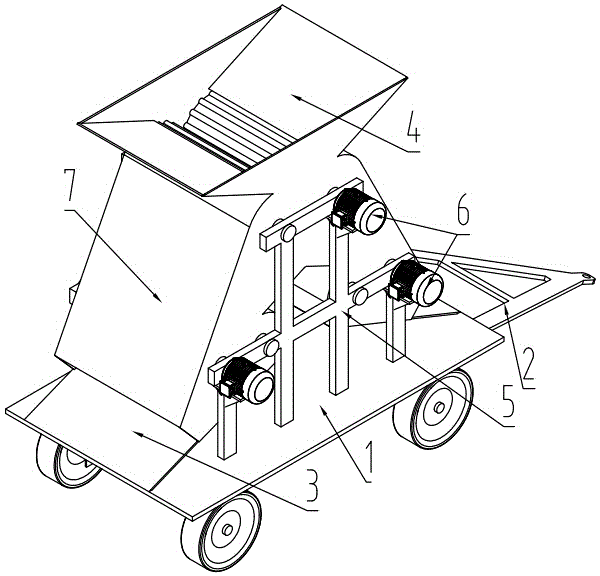

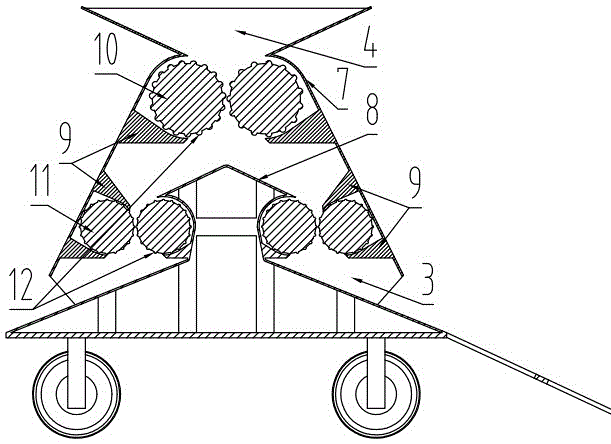

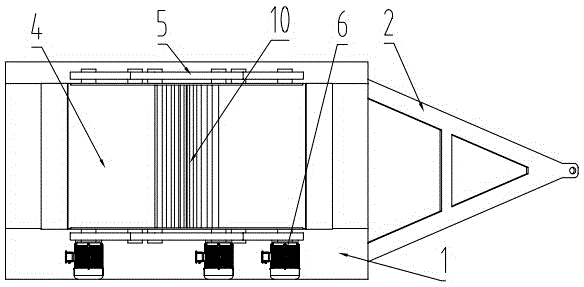

[0014] like figure 1 , figure 2 , image 3 ,and Figure 4 As shown, a building waste crushing device includes a chassis 1, a bracket 5, a primary pressure roller 10 and a secondary pressure roller 11; Drag the removed bracket 2; the bracket 5 is fixed on the chassis 1, and one side of the bracket 5 is designed to provide three pairs of pressure rollers (one pair of primary pressure rollers 10 and two pairs of secondary pressure rollers 11). Power drive motor 6; the primary pressure roller 10 is placed on the support 5, the upper side is designed with a waste material inlet 4, and a stripper block 9 is designed around it to prevent the material from adhering to the primary pressure roller 10 , affec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com