High-voltage static cooking fume removing device

A fume device and high-voltage electrostatic technology, which is applied in the field of fume removal device, can solve the problems of insufficient strength, installation stability, inability to discharge oil in time, troublesome installation and disassembly, etc., so as to avoid ignition and arcing and ensure power supply Safe and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

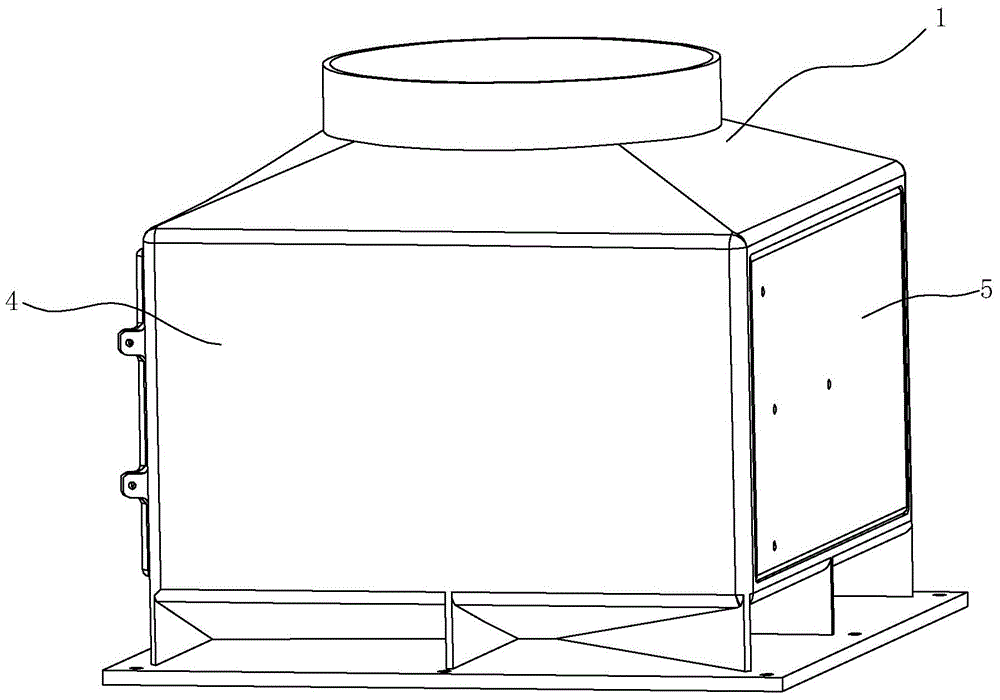

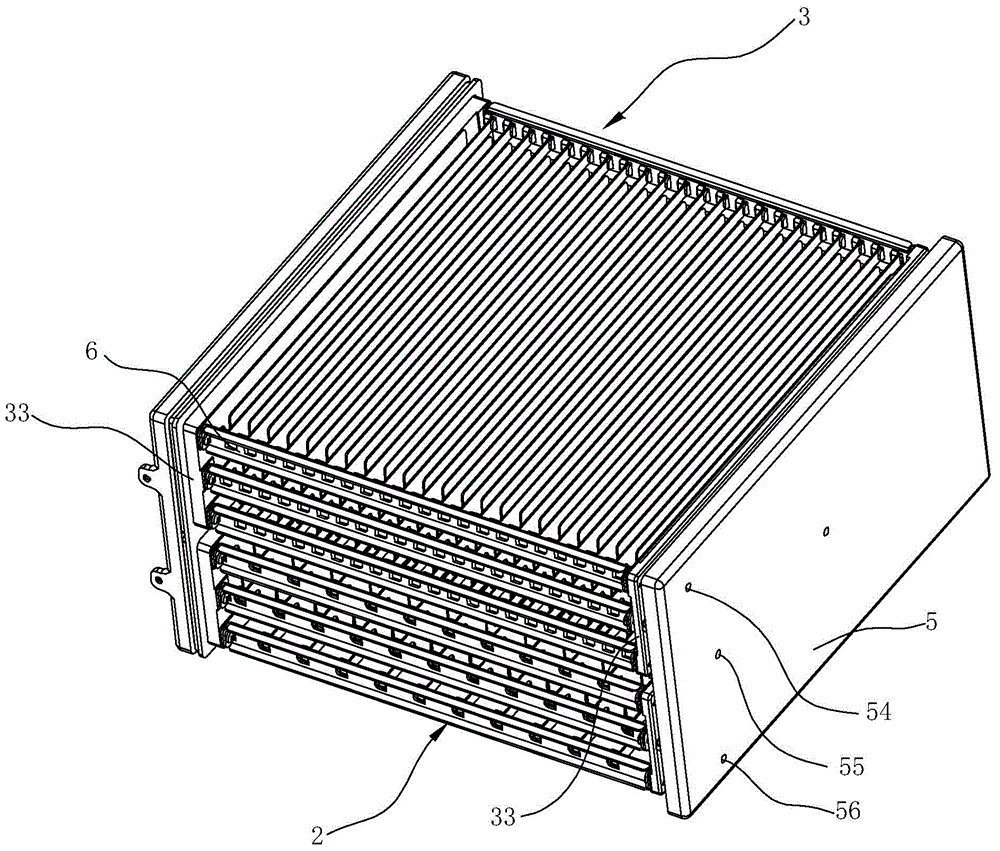

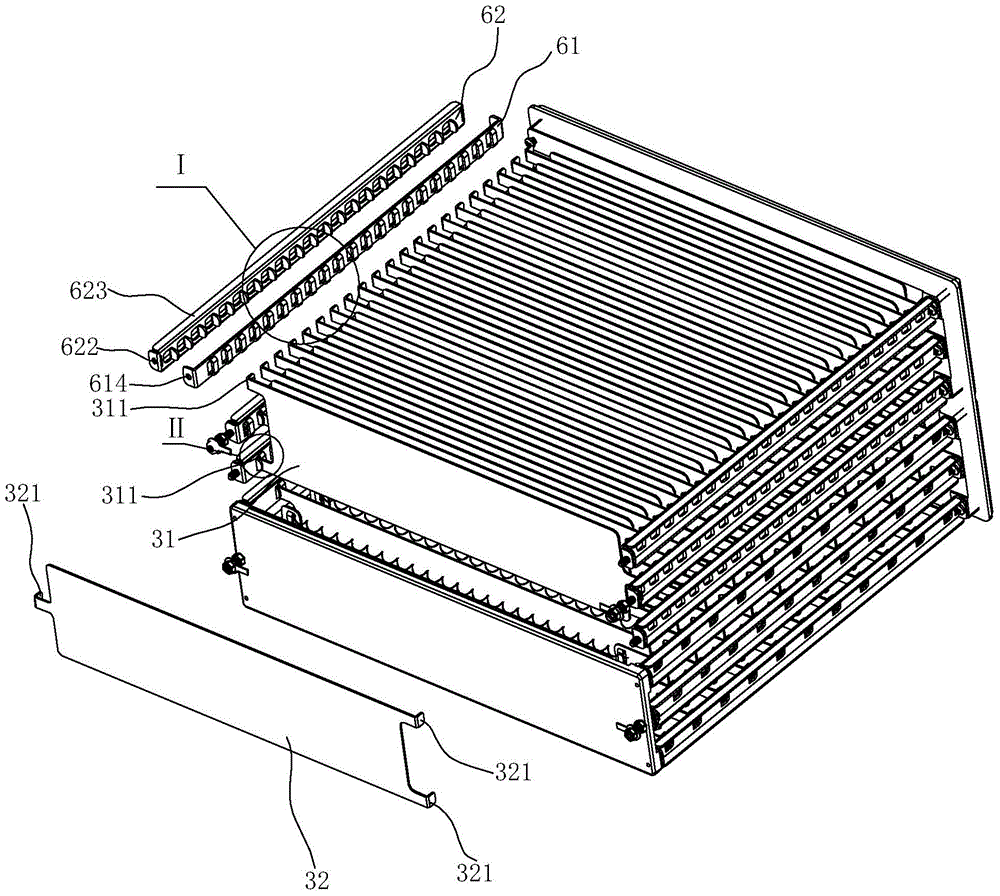

[0021] see figure 1 ~ Figure 4, a high-voltage electrostatic oil fume removal device, which can be installed above the air outlet of the centrifugal fan of the range hood, includes an insulating shell 1, an independent ionization module 2 and a dust collection module 3 placed in the shell 1.

[0022] The front side of the casing 1 has an opening 11, so that the ionization module 2 and the dust collection module 3 can be assembled and disassembled from the front side of the casing 1; the bottom surface also has an opening 12, so that the oil fume enters the electrostatic oil fume purification device from the bottom surface of the casing 1 for purification . The front side opening 11 of the casing 1 is provided with a panel 4, the height and length of the panel 4 match the height and length of the ionization module 2 and the dust collection mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com