Reciprocating extrusion upsetting device and its using method and application

A pie-shaped, punch technology, applied in forging/pressing/hammer devices, manufacturing tools, forging/pressing/hammering machines, etc., can solve the problems of easy cracking and restrict application, and reduce the tendency of cracking and grain size. Small dispersion, avoiding the effect of squeezing dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

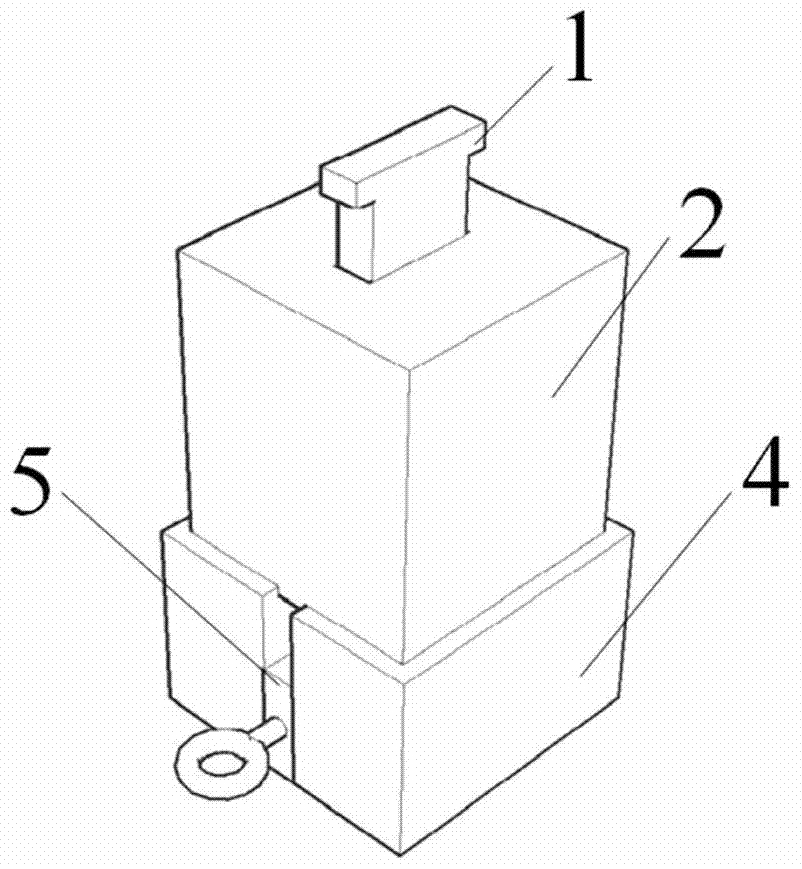

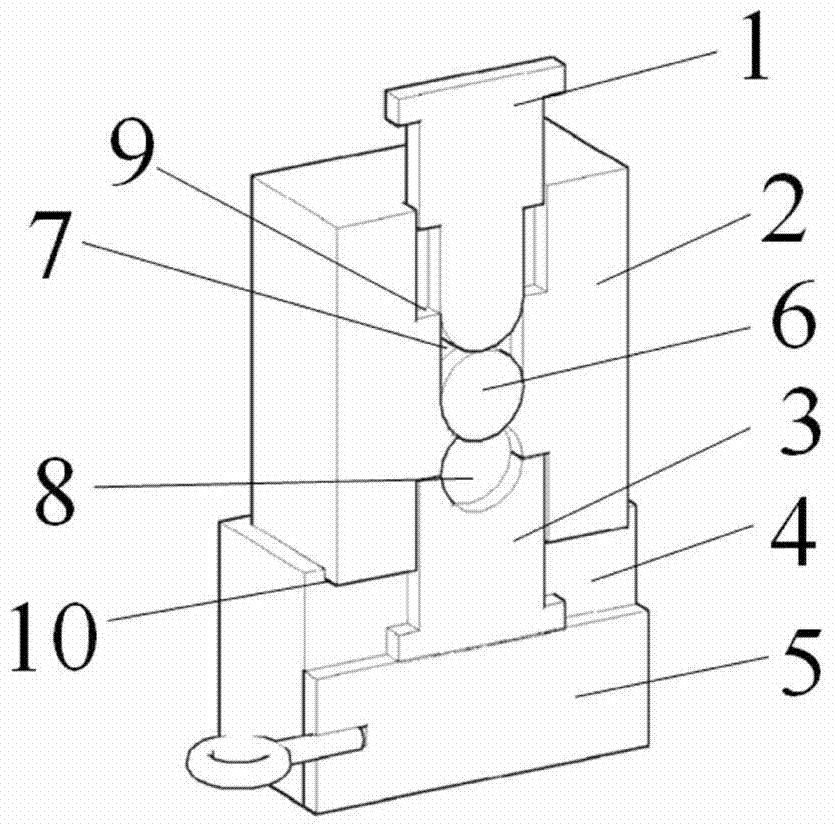

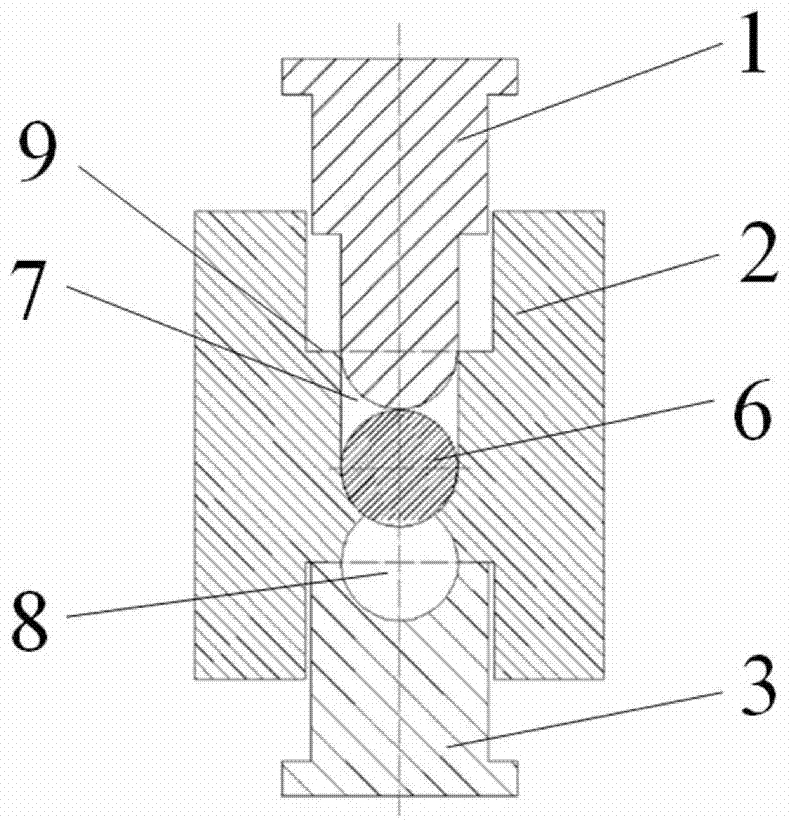

[0037] The present invention provides a reciprocating extruding device for preparing ultra-fine crystal cake-shaped materials, its structure is as shown in the figure figure 1 , figure 2 and image 3 As shown, it includes: an upper punch 1, a die 2, a lower punch 3, a base 4, and a pad 5; the base 4 is detachably arranged at the bottom of the die 2, and the die 2 is provided with a necking area. The necking area divides the interior of the die 2 into an upper cavity 7 and a lower cavity 8 that communicate with each other; the inner side of the bottom of the upper cavity 7 is arc-shaped with an extrusion port; the inner side of the lower cavity 8 is also arc-shaped , the arc inside the upper cavity 7 has the same radius as the arc inside the lower cavity 8 .

[0038] The lower end of the upper punch 1 cooperates with the bottom end of the upper cavity 7 of the die 2, and the upper end of the upper punch 1 cooperates with the inner step 9 of the upper cavity 7 of the die 2, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com