Aluminum veneer cutting equipment

A technology of cutting equipment and aluminum veneer, which is applied in metal sawing equipment, metal processing equipment, sawing machine devices, etc., can solve the problems affecting the efficiency of aluminum veneer cutting, low degree of automation, and complicated operation, so as to improve safety. high degree of automation, simple and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

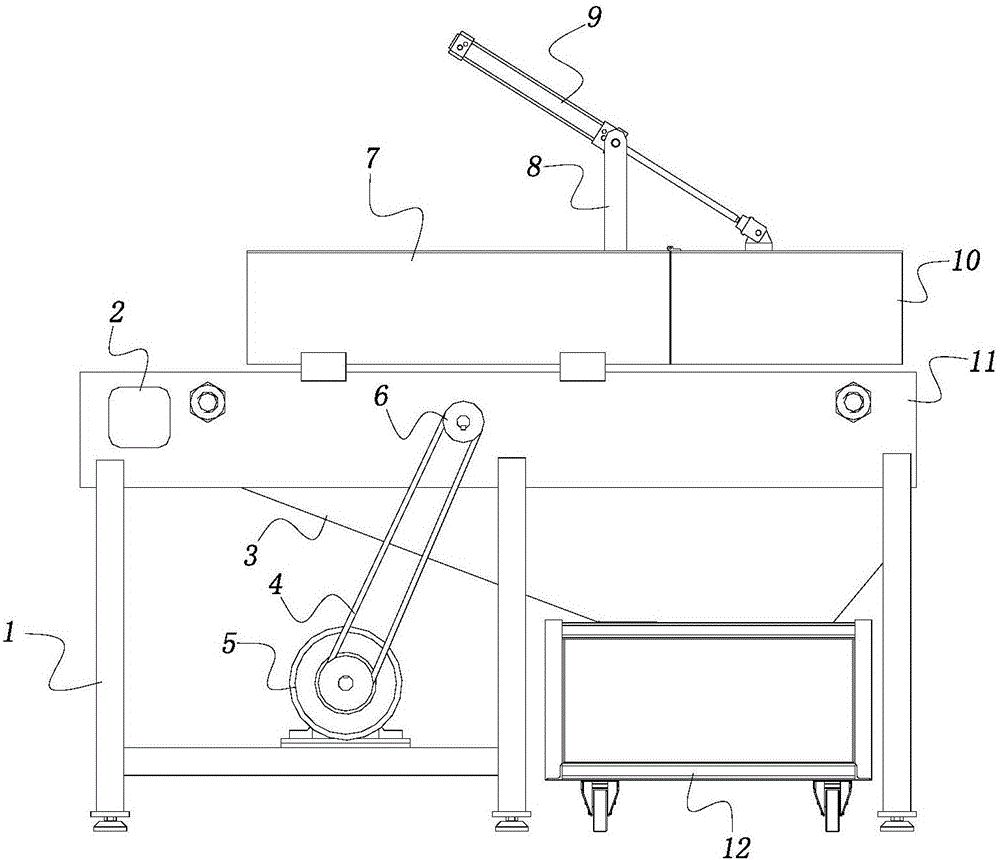

[0014] See Figure 1 to Figure 3 , the present invention includes a feeding and cutting device supported by a plurality of columns 1 .

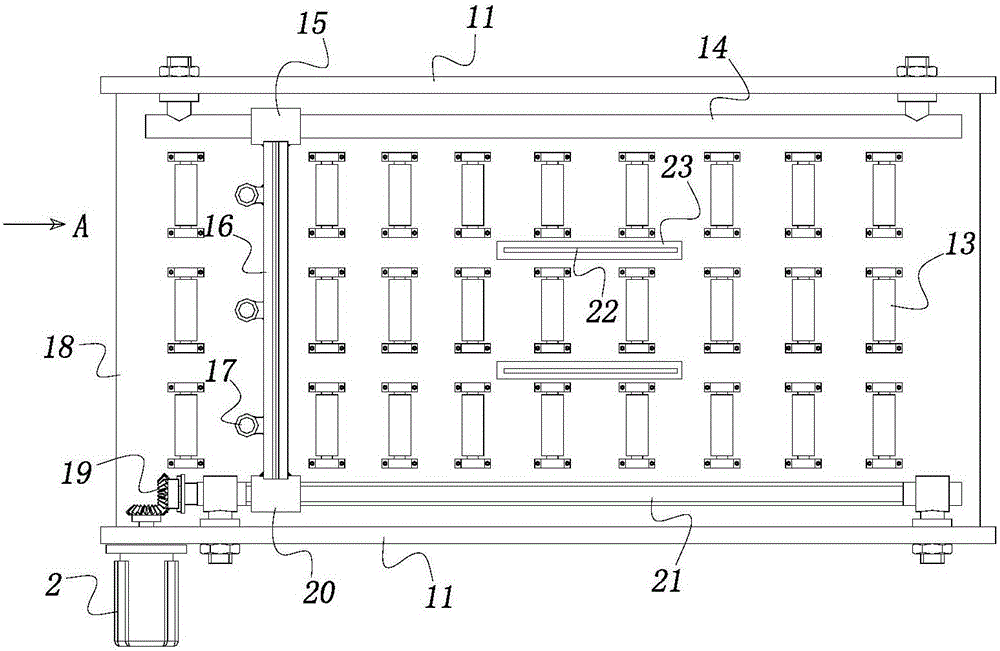

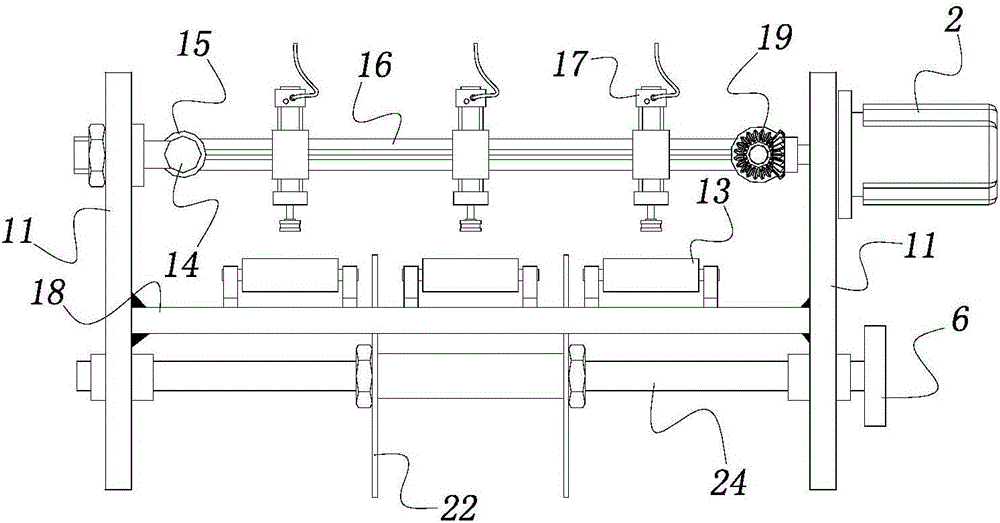

[0015] The straight bottom plate 18 of the feeding and cutting device is vertically fixed with side plates 11 on both sides of the bottom plate 18 respectively.

[0016] A guide rod 14 with a sliding sleeve 15 is installed on the inside of one of the side plates 11, and a lead screw 21 with a nut 20 is installed on the inside of the other side plate 11. The center line of the guide rod 14 is aligned with the wire. The centerlines of the bars 21 are parallel, and the plane where the centerlines of the two are located is parallel to the upper surface of the bottom plate 18 . The above-mentioned two side plates 11 not only constitute the mounting brackets for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com