Spray head structure of combined 3D printer

A technology of 3D printers and nozzles, applied in the direction of additive processing, etc., can solve problems such as poor product quality, poor sealing, and overflow of melted materials, and achieve the effects of avoiding environmental pollution, improving quality, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

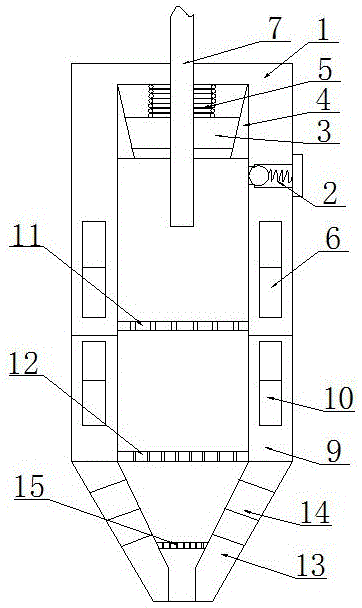

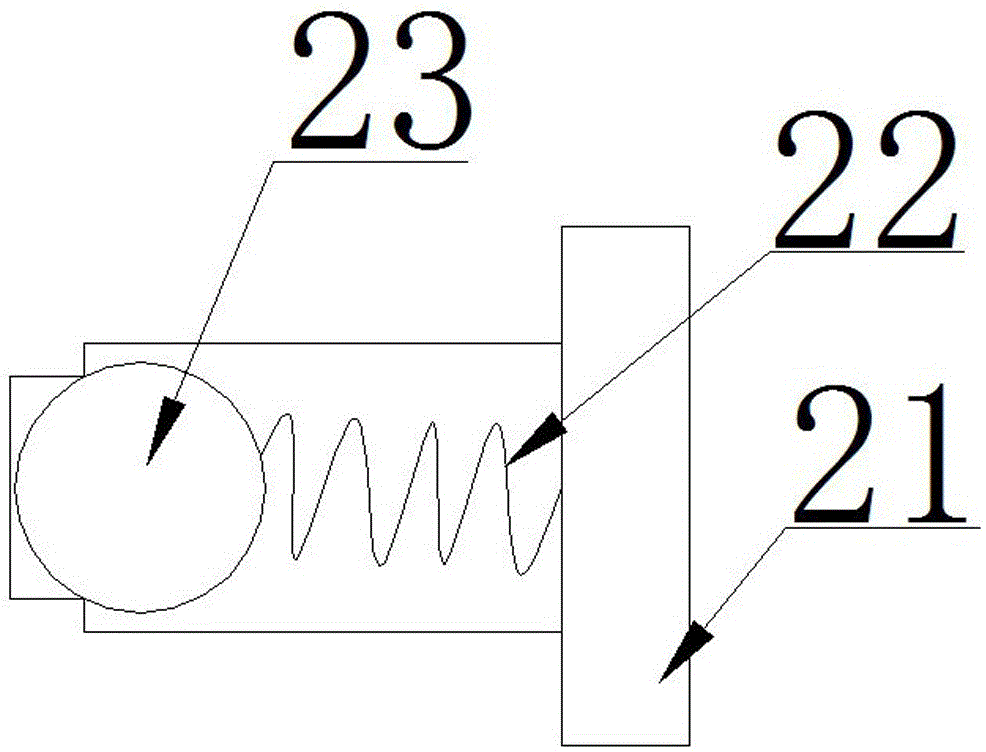

[0011] Figure 1-2 Shown is a nozzle structure of a combined 3D printer provided by the present invention, including: a feed housing 1, an electric heating wire heating ring 6, an exhaust device 2, an infrared heater 10, a sealing ring 3, a limit ring 4, Intermediate housing 9 , nozzle housing 13 , hot water heat conduction layer 14 , first filter screen 11 , second filter screen 12 , gas 23 , exhaust spring 22 , purifier 21 , third filter screen 15 and spring 5 . The feed end in the feed housing 1 is fixedly provided with a limit ring 4, the inner circular surface of the limit ring 4 is a conical surface, and the inner circular surface of the limit ring 4 is provided with a sealing ring 3 matched with the conical surface, A spring 5 is arranged between the sealing ring 3 and the inlet end face in the feed housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com