Door leaf vacuum thermal transfer printer

A technology of vacuum heat and transfer printing machine, applied in rotary printing machine, printing machine, transfer printing and other directions, can solve the problems of low transfer efficiency, poor authenticity of transfer pattern, increase in production cost, etc., to improve transfer efficiency , The transfer effect is good, and the effect of improving the transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

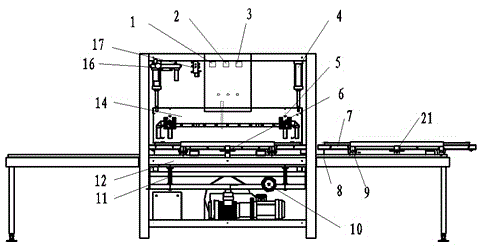

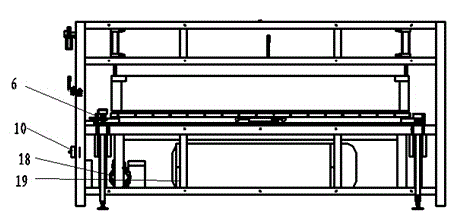

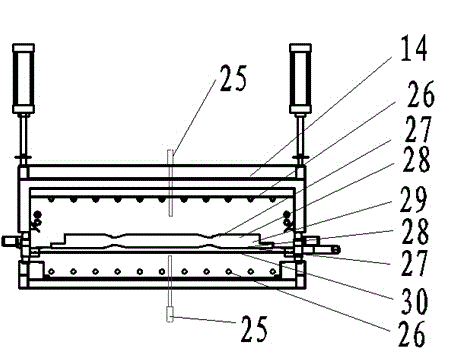

[0014] As an embodiment of the present invention, such as figure 1 , 2 As shown in , 3, a door leaf vacuum heat transfer machine, including a body frame, is characterized in that: a cylinder 4 is arranged on the upper end of the body frame, the cylinder is connected to the air source processor 16, and the lower end of the cylinder push rod is fixedly connected There is an upper heating chamber 14, and a lower heating chamber 12 is fixedly installed on the lower side of the body frame. A slide rail 8 is arranged between them, and the slide rail passes through the frame of the body. The slide rail is divided into three sections, left, middle, and right. There is a sealed chamber 7, the bottom of the sealed chamber is provided with a pulley 9 matching with the slide rail 8, a trigger block 21 is arranged on the side of the sealed chamber to cooperate with the travel switch 6 arranged on the body frame, and a vacuum valve is arranged at the bottom of the body frame. The vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com