Novel light hanging decorating plate and manufacture method thereof

A decorative board, lightweight technology, used in construction, building construction, covering/lining, etc., can solve the problems of paint peeling, complex construction, fading, etc., to facilitate the improvement of production efficiency, facilitate the turnover of molds, and reduce the environment. load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

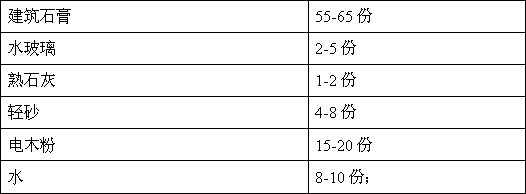

Embodiment 1

[0034] Weigh the surface layer raw materials according to the proportion, and the mass ratio is composed of 55% quartz sand, 0.2% bakelite powder, 18% high aluminate cement, 18% emulsion and 8.8% water; the weighed raw materials Mix well and pour into a glass plate mold with a transfer film, about 3mm thick. Spread a layer of grid cloth on the evenly spread surface layer slurry. Weigh various bottom raw materials, according to the mass ratio of 55% building gypsum, 5% water glass, 2% slaked lime, 8% light sand, 20% bakelite powder and 10% water composition, will weigh good Mix the raw materials evenly, and spread them on the above-mentioned mesh cloth, with a thickness of about 5 mm. Put the above product into an oven at 70°C for 2 hours, take it out after cooling, and remove the protective film of the transfer film to obtain the finished product.

Embodiment 2

[0036] Weigh the surface layer raw materials according to the proportion, and the mass ratio is composed of 55% quartz sand, 0.2% bakelite powder, 18% high aluminate cement, 18% emulsion and 8.8% water; the weighed raw materials Mix well and pour into a glass plate mold with a transfer film, about 3mm thick. Spread a layer of grid cloth on the evenly spread surface layer slurry. Weigh various bottom raw materials, according to the mass ratio of 61% building gypsum, 4% water glass, 2% slaked lime, 7% light sand, 17% bakelite powder and 9% water composition, will weigh good Mix the raw materials evenly, and spread them on the above-mentioned mesh cloth, with a thickness of about 5 mm. Put the above product into an oven at 70°C for 2 hours, take it out after cooling, and remove the protective film of the transfer film to obtain the finished product.

Embodiment 3

[0038] Weigh the surface layer raw materials according to the proportion, and the mass ratio is composed of 55% quartz sand, 0.2% bakelite powder, 18% high aluminate cement, 18% emulsion and 8.8% water; the weighed raw materials Mix well and pour into a glass plate mold with a transfer film, about 3mm thick. Spread a layer of grid cloth on the evenly spread surface layer slurry. Weigh various bottom raw materials, according to the mass ratio of 65% building gypsum, 5% water glass, 2% slaked lime, 6% light sand, 12% bakelite powder and 10% water composition, will weigh good Mix the raw materials evenly, and spread them on the above-mentioned mesh cloth, with a thickness of about 5 mm. Put the above product into an oven at 70°C for 2 hours, take it out after cooling, and remove the protective film of the transfer film to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com