Method for printing patterns on inorganic board through heat transfer

A technology of thermal transfer printing and thermal transfer film, which is applied in the process of producing decorative surface effects, decorative art, etc., can solve the problems of applying inorganic plates without thermal transfer printing technology, and achieve shortening of on-site processing time and adhesion Strong, increased weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

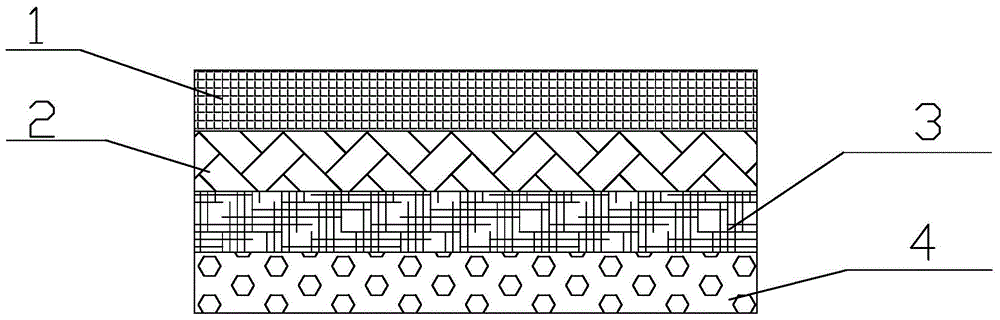

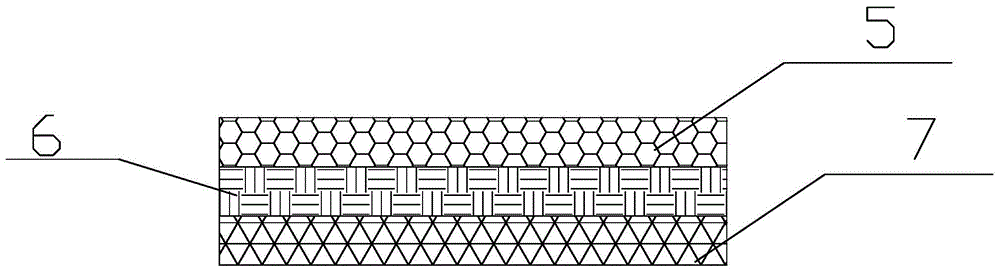

Image

Examples

Embodiment 1

[0030] A standard calcium silicate board with a specification of 1220*2440*6mm is used as the base material.

[0031] A method for heat-transfer printing patterns on inorganic plates, the steps are as follows:

[0032] 1) Input the plate into the sanding equipment, use the sanding belt of the sanding equipment to sand the surface of the substrate, and remove the dust on the surface;

[0033] 2) Apply thermal transfer primer on the surface of the dust-removed board, and then level off and dry with infrared rays, so that the primer can be evenly coated and semi-dry. The semi-dry state is that the surface of the paint film is not sticky when touched the state of the hand;

[0034] 3) After hot stamping the thermal transfer film on the surface of the board treated in step 2), peel off the base layer of the thermal transfer film.

[0035] 4) After placing the above-mentioned plates treated in step 3) in a ventilated place for 12-24 hours, use electrostatic dust removal to remove du...

Embodiment 2

[0043] A standard silicate plate with a specification of 1220*2440*6mm is used as the substrate.

[0044] A method for heat-transfer printing patterns on inorganic plates, the steps are as follows:

[0045] 1) Input the plate into the sanding equipment, use the sanding belt of the sanding equipment to sand the surface of the substrate, and remove the dust on the surface;

[0046] 2) Apply thermal transfer primer on the surface of the dust-removed board, and then level off and dry with infrared rays, so that the primer can be evenly coated and semi-dry. The semi-dry state is that the surface of the paint film is not sticky when touched the state of the hand;

[0047] 3) After hot stamping the thermal transfer film on the surface of the board treated in step 2), peel off the base layer of the thermal transfer film.

[0048] 4) After placing the above-mentioned plates treated in step 3) in a ventilated place for 12-24 hours, use electrostatic dust removal to remove dust from th...

Embodiment 3

[0056] The reinforced fiber cement board with a specification of 1220*2440*6mm is used as the base material.

[0057] A method for heat-transfer printing patterns on inorganic plates, the steps are as follows:

[0058] 1) Input the plate into the sanding equipment, use the sanding belt of the sanding equipment to sand the surface of the substrate, and remove the dust on the surface;

[0059] 2) Apply thermal transfer primer on the surface of the dust-removed board, and then level off and dry with infrared rays, so that the primer can be evenly coated and semi-dry. The semi-dry state is that the surface of the paint film is not sticky when touched the state of the hand;

[0060] 3) After hot stamping the thermal transfer film on the surface of the board treated in step 2), peel off the base layer of the thermal transfer film.

[0061] 4) After placing the above-mentioned plates treated in step 3) in a ventilated place for 12-24 hours, use electrostatic dust removal to remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com