A method of manufacturing an anti-riot compartment structure

A manufacturing method and technology for carriages, which are applied in the direction of load-bearing body structures, superstructures, vehicle components, etc., can solve the problems of heavy, unsafe, and complicated structures of carriages, and achieve simple skeleton splicing process, high material utilization rate, and overall shape. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

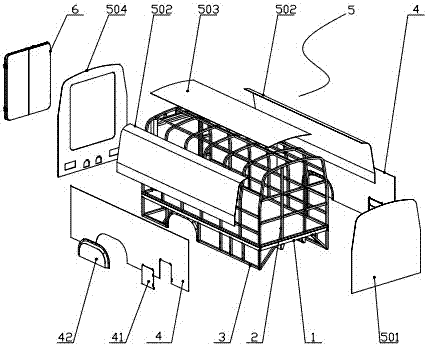

[0044] Such as figure 1 As shown, an anti-riot compartment structure includes an underframe 1, a body frame 2, a lower apron frame 3, a body panel 5, and a rear door assembly 6; The lower apron panel4. The added tire guard 42 and the fuel tank door 41 effectively protect the tires and the fuel tank.

[0045] The body panel 5 includes a front wall panel 501 , two side wall panels 502 , a roof panel 503 and a rear wall panel 504 . The body frame 2 is welded on the chassis 1; the gap between the edges of each body panel 5 is within 5mm, and the section welding is fixed on the body frame 2; the body panel 5 and the lower apron panel 4 are bulletproof panels, which have the function of bulletproof and anti-riot .

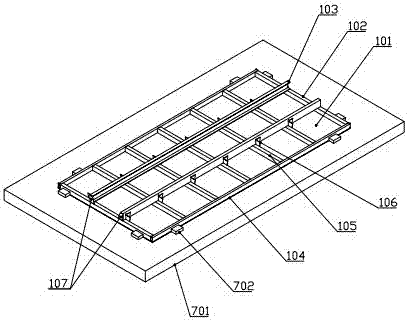

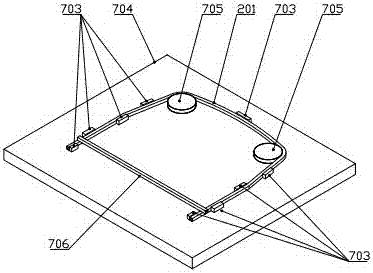

[0046] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 Shown, a kind of manufacturing method of anti-riot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com