Vehicle frame connector on shock absorber

A technology for connecting joints and shock absorbers, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., and can solve the problem of inability to install, screw in the screw, welding slag easily falling into the internal threaded hole 1a, etc. Problems, to achieve good practicality, highly reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

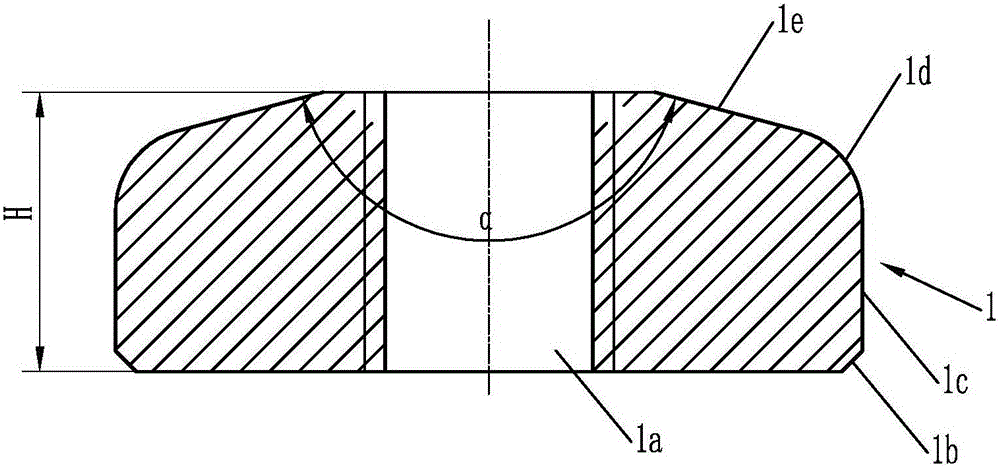

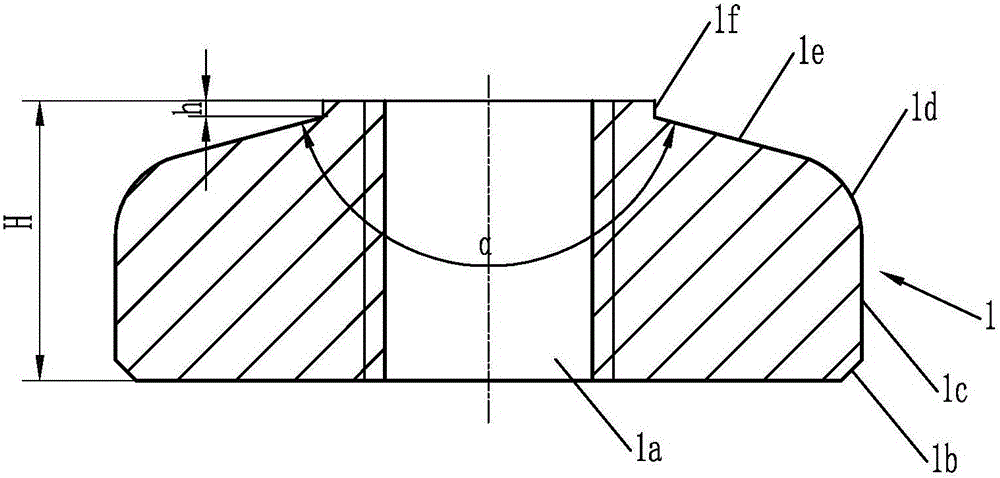

[0017] Such as figure 2 As shown, a frame connection joint on a shock absorber, the body 1 of the joint is a rotary structure, the manufacturing material is 20 steel, and the overall height H of the body 1 is 13.5 mm. An internally threaded hole 1a is opened in the center of the body 1 in the axial direction. The internally threaded hole 1a is a through hole penetrating through the top and bottom surfaces of the body 1. The internally threaded hole 1a is used for connecting a screw. In addition, the parameter of the internally threaded hole 1a is M12*1.25-7H.

[0018] The bottom surface of the body 1 is connected to the lower end of the cylindrical section 1c through the chamfered section 1b, the parameter of the chamfered section 1b is 1*45°, and the diameter of the cylindrical section 1c is 36mm. The upper end of the cylindrical section 1c is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com