Deep dehydration method for excess sludge of urban sewage plant

A technology for deep dewatering and excess sludge, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problem of high labor cost or energy consumption, save investment and manpower, and achieve the effect of high-efficiency deep dewatering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

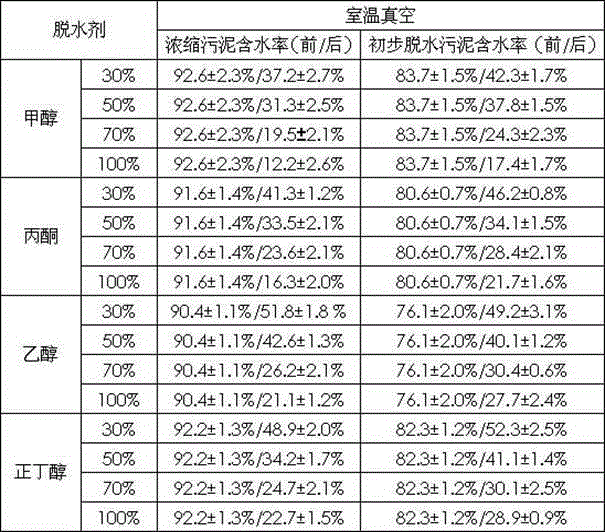

[0020] Take 30mL, 50mL, 70mL formaldehyde, ethanol, acetone and n-butanol respectively, mix with 70mL, 50mL, 30mL pure water to prepare formaldehyde, ethanol, acetone and n-butanol solutions with concentrations of 30%, 50%, 70%, and Take 100mL of each solution with a concentration of 100% for use, and put 100mL of the above solution into a 250mL Erlenmeyer flask.

[0021] Take 30±5g of the concentrated sludge from the secondary sedimentation tank and the sludge after mechanical dehydration into organic solutions of different concentrations, place them in a shaker at room temperature (25±3°C), and mix for 30 minutes at 120±5rpm;

[0022] Use qualitative filter paper to filter the mixed sludge mixture. After the filtration, the sludge sample is flattened and dried at room temperature (25±3°C) until the moisture content no longer changes, and the deep dehydration process is completed.

[0023] The results showed that the higher the concentration of dehydrating agent, the lower th...

Embodiment 2

[0025] Take 30mL, 50mL, 70mL formaldehyde, ethanol, acetone and n-butanol respectively, mix with 70mL, 50mL, 30mL pure water to prepare formaldehyde, ethanol, acetone and n-butanol solutions with concentrations of 30%, 50%, 70%, and Take 100mL of each solution with a concentration of 100% for use, and put 100mL of the above solution into a 250mL Erlenmeyer flask.

[0026] Take 30±5g of the concentrated sludge from the secondary sedimentation tank and the sludge after mechanical dehydration into organic solutions of different concentrations, place them in a shaker at room temperature (25±3°C), and mix for 30 minutes at 120±5rpm;

[0027] Put the 0.45μm filter membrane into the vacuum filtration device, then pour the sludge mixture into the device, and carry out vacuum filtration at room temperature (25±3°C) under a pressure of 100-400mmHg until the moisture content does not change That is to complete the deep dehydration process.

[0028] The results showed that the higher the...

Embodiment 3

[0030] Take 30mL, 50mL, 70mL formaldehyde, ethanol, acetone and n-butanol respectively, mix with 70mL, 50mL, 30mL pure water to prepare formaldehyde, ethanol, acetone and n-butanol solutions with concentrations of 30%, 50%, 70%, and Take 100mL of each solution with a concentration of 100% for use, and put 100mL of the above solution into a 250mL Erlenmeyer flask.

[0031] Take 30±5g of the concentrated sludge from the secondary sedimentation tank and the sludge after mechanical dehydration into organic solutions of different concentrations, place them in a shaker at room temperature (25±3°C), and mix for 30 minutes at 120±5rpm;

[0032] Use qualitative filter paper to filter the mixed sludge mixture. After the filtration is completed, the sludge samples are flattened and placed in constant temperature drying boxes at 65, 80, and 120°C, until the moisture content does not change, and the deep dehydration is completed. process.

[0033] The results showed that the higher the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com